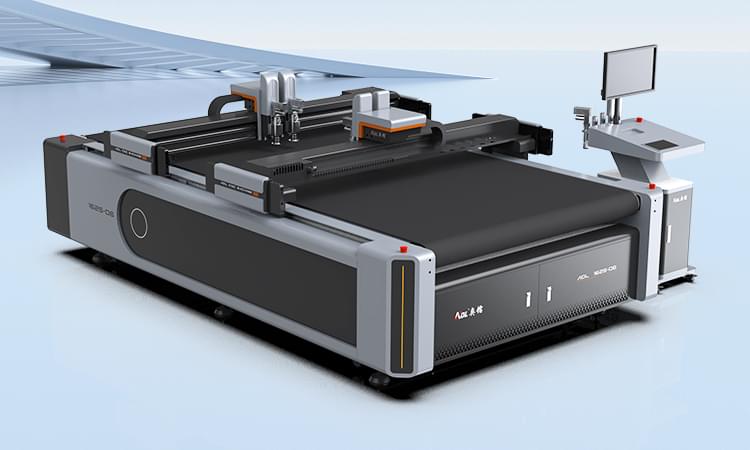

Automatic CNC Cardboard Cutting Machine with Vibrating Tangential Knife is an industrial CNC cardboard box making machine for the packaging industry with a wide range of knives and blades to cut cardboard, cardboard, cartons, corrugated boxes, corrugated cardboard, paperboard, dunnage and chipboard.

Unlike standard CNC cutting machines, which primarily use rotating cutting tools such as end mills and saws, blade cutting machines employ blades that move in multiple directions to create intricate and precise cuts.

When considering a tangential knife CNC router, it is important to evaluate your specific application requirements, such as the type of material to be cut, the required cutting accuracy, and the desired machine size and capabilities.

Features of plastic and cardboard CNC cutting machine:

1. Multi-Material Compatibility: These machines are suitable for cutting a wide range of materials, including foam, cardboard, gasket materials, vinyl, leather, textiles, and a variety of flexible

2. Precision and Detail: CNC cutting machines are known for their high precision, making them ideal for applications that require intricate details, sharp corners, and clean cuts.

3. Versatile Cutting: In addition to straight cuts, tangent cutters can also make V-cuts, bevel cuts, creasing, perforations, and kiss cuts (cutting a layer while leaving the backing material intact), which expands their versatility.

4. Automatic Tool Changing: Some models are equipped with an automatic tool changer, allowing for quick switching between different tool types or angles.

5. Contour Cutting: These machines excel at contour cutting, producing custom shapes, graphics, labels, and patterns with high precision.

6. Integration with Design Software: Tangential Knife CNC Routers are compatible with a variety of CAD/CAM design software, allowing for seamless integration and precise control of cutting patterns.

CNC plastic and cardboard cutting machines are used in the cutting, creasing, dotted line, marking, drawing and other processes in the packaging industry, replacing the manual development, design and proofing of traditional cartons and display racks, shortening the R&D time, with fast proofing and high quality. CNC carton cutting machines do not require knife molds or die-cutting machines to complete die-cutting, creasing and forming of flexible materials such as paper and plastic, saving a lot of manpower and mold costs.

What materials can be cut with CNC vibration cutting machine

Textiles, fabrics, leather, fiberglass, rubber, stickers, films, foam boards, corrugated boards, cardboards, plastic boxes, clothes, gasket materials, footwear materials, clothing materials, bag materials, carpets, sponges, carpets, PU, PP, PE, PTFE, ETFE, EVA, XPE, PVC and composite materials.

AOL intelligent blade cutting machine has high precision and high efficiency. Our professional after-sales service can provide automatic cutting solutions for various industries.

For more information, please consult:

Email: [email protected]

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://aollaser.net/