In the process of producing leather products, no matter which product is made, it needs to be cut according to the shape and size of the product. Therefore, cutting is an indispensable process in production. There are many ways to cut leather, which can be cut, cut, cut, carved, etc. In the past, these methods were all done by hand, and low efficiency and waste of materials were a common problem faced by many manufacturers. Now with the advent of fully automatic belt cutting machines, these problems no longer exist. Today, Xiaobian will introduce this leather cutting machine in detail to you.

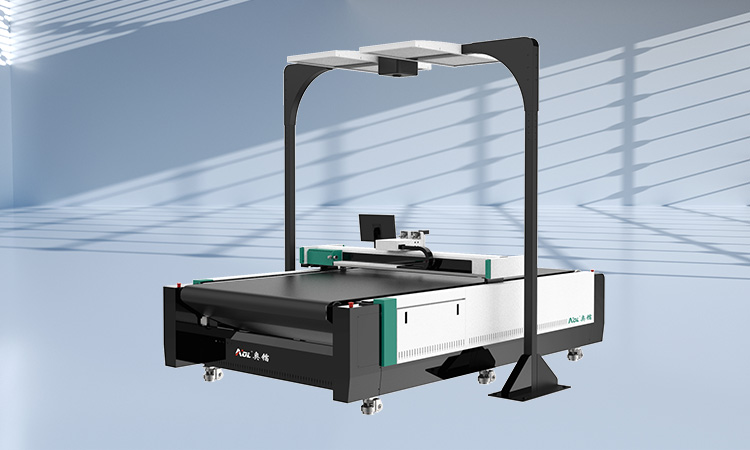

There are two kinds of equipment for cutting leather, one is cutting with laser machine, the other is cutting with vibrating knife. AOL belt cutting machine adopts vibrating knife blade for cutting. Compared with laser machine, blade cutting is more accurate and environmentally friendly. And there is no need to manually make patterns and sketches, just import the data into the computer to cut. Many manual cutting steps are eliminated. One piece of equipment can work continuously for 24 hours, maximizing the productivity. This makes it easier, more convenient and more efficient to cut leather belts and genuine leather!

The two functions of automatic loading and unloading and super nesting can solve the problem of wasting materials and labor to a great extent. Automatic loading and unloading can make the leather and leather materials uninterruptedly transported to the cutting machine for cutting work, which can make the materials used to a higher degree. In terms of labor saving, one equipment can replace 3-5 labors, and one person can watch multiple devices. It really solves the labor cost and material cost, saving you money!

At the same time, our machine also takes into account the actual use environment of customers, and is specially equipped with an anti-interference operation screen, which is not affected by the surrounding electronic environment during work, and special treatment of lines and interfaces makes it safer to cut conductive materials.

The weight of the whole machine is more than 1.5 tons, and the high-speed operation does not vibrate. The equipment must undergo 72 hours of uninterrupted high-load proofing and trial cutting before leaving the factory.

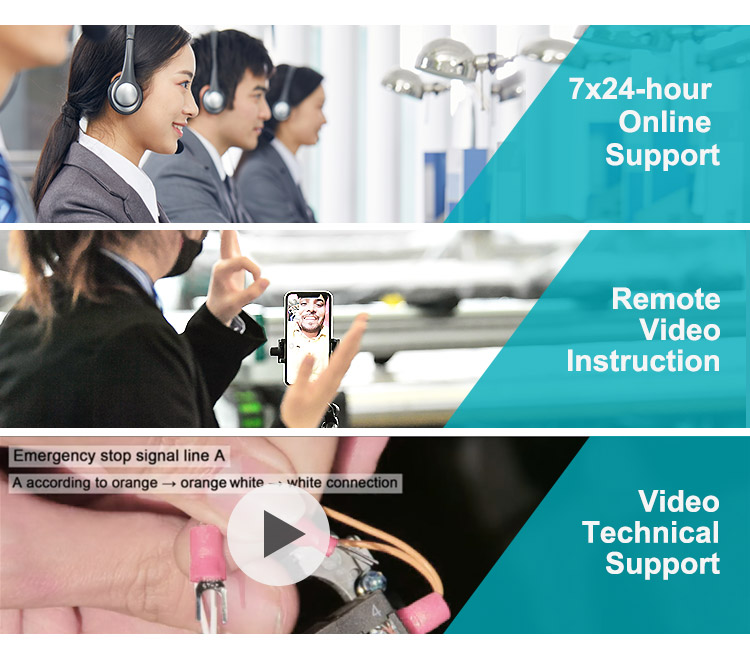

If you use the equipment well in cutting, it will completely allow you to reduce labor costs, ensure quality, and increase your output. At present, the general model of equipment for cutting belts and leather materials is 1625. Of course, it can also be customized according to your needs. If you encounter any problems during the cutting process, you can contact us!