What are the latest developments in gasket cutting machines?

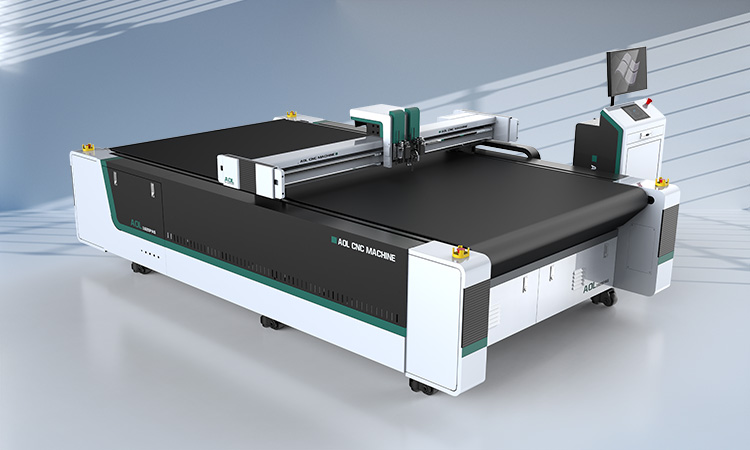

Recent advances in gasket cutting machines are having a major impact on manufacturing. Modern machines are equipped with the latest software, allowing for automation and gasket design customization. CNC technology enables gasket cutters to quickly produce gaskets that match complex shapes and sizes, reducing the need for manual intervention. In addition, the new equipment has higher cutting capacity, greater efficiency and reduced energy consumption, making it more sustainable and cost-effective.

What are the emerging technologies in the gasket cutting industry?

The gasket cutting industry is constantly evolving, with emerging technologies at the forefront. Some of the latest technologies in the industry include blade cutters, lasers, water jets, and ultrasonic cutters. CNC blade cutting machines use cold cutting to cut gasket materials accurately and quickly. On the other hand, blade cutting is a more environmentally friendly cutting method and can ensure a smooth and flat cutting surface without the need for secondary processing!

How will gasket cutters impact manufacturing in the future?

Gasket cutting machines are rapidly evolving and their impact on manufacturing is set to increase. The increasing use of digital technology and software automation will enable more precise and sophisticated gasket designs. Combining different cutting technologies will also result in a more efficient and environmentally friendly manufacturing process. For example, using water jets to cut gaskets can reduce the need for lubricants and coolants, thereby reducing emissions and waste. The use of blade cutting machines can reduce environmental pollution caused by laser cutting. In the future, the manufacturing industry will increasingly rely on advanced gasket cutting machines to improve efficiency, reduce costs and improve product quality.

What are the predictions for the future of gasket cutters?

A major shift to gasket cutters will mark the future of manufacturing. More manufacturers will invest in advanced gasket cutting machines, thereby increasing the adoption and innovation of new technologies. Demand for custom and durable gasket designs will increase, leading to greater investment in advanced software automation and cutting technology. Niche players in the gasket cutting industry will emerge, offering specialized gasket designs and further driving innovation.

How to keep up to date with the latest trends in gasket cutting machines?

It is vital for anyone in the manufacturing industry to understand the latest trends in gasket cutting machines. Some resources to keep you informed include trade shows, industry conferences, and online forums. These events allow professionals to network and learn about the latest trends and technologies. Additionally, industry journals, magazines, and industry newsletters provide detailed insights into gasket cutting industry trends. Manufacturers can subscribe to supplier newsletters and follow industry thought leaders on social media platforms for the latest updates.

FAQ:

Q: What is a gasket cutting machine?

A: The gasket cutting machine is used to cut rubber, cork, silicone, plastic, sponge and other gasket and sealing materials.

Q: What are the different types of gasket cutters?

A: There are many types of gasket cutting machines, including CNC gasket cutting machines, knife cutting machines, digital cutting machines and automatic gasket cutting machines.

Q: How does the cutter work?

A: Cutter uses a sharp blade to cut rubber, plastic and sponge. The edge is held in place by a knife guided by the cutting table.

Q: What is the difference between CNC cutting machine and automatic cutting machine?

A: CNC cutting machines are usually operated by a skilled operator inputting cutting parameters, while automatic cutting machines use a set of pre-programmed cutting parameters and work without human intervention.

Q: How to ensure that the gasket is cut smoothly?

A: To ensure smooth cutting of the gasket, it is crucial to select the appropriate cutting system and use the correct tool. Additionally, the material should be compressed to prevent movement during cutting, and a suction platform or vacuum table can be used to hold the fabric in place.

AOL intelligent blade cutting machine has high precision and high efficiency. Our professional after-sales service can provide automatic cutting solutions for various industries.

For more information, please consult:

Email: [email protected]

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://aollaser.net/