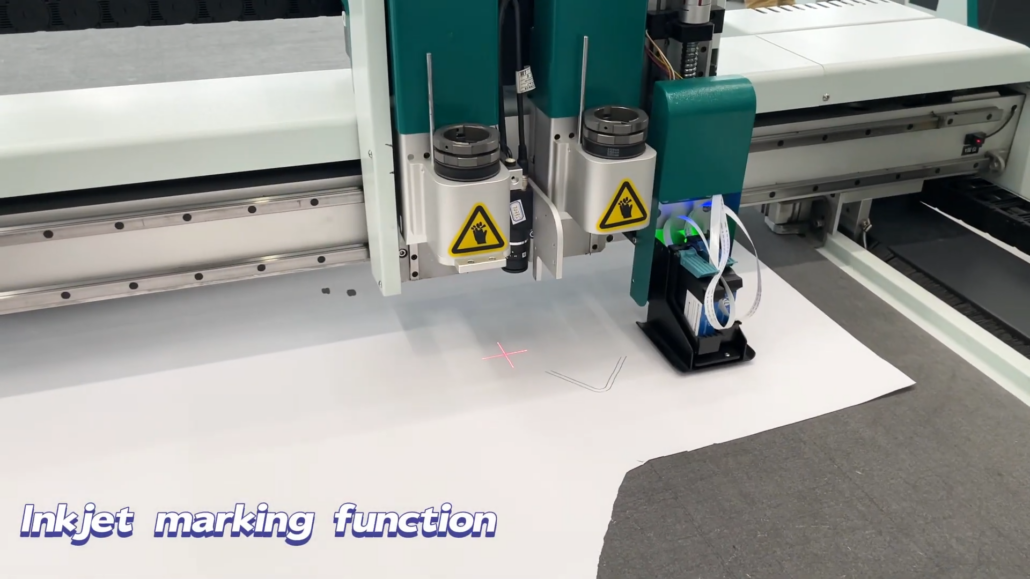

AOL CNC cutting equipment is a standard workhorse for businesses of all sizes. This cutting machine focuses on intelligently cutting non-metallic materials into a variety of designs. It can quickly complete various operations such as full cutting, half cutting, drilling and milling, punching, creasing and marking, easily solving production efficiency problems in sample making and small batch production. Many flexible materials need to be marked before cutting, and AOL technicians have newly added inkjet technology for marking materials to improve material utilization and accuracy.

The advent of smart cutting machines with inkjet marking technology is revolutionizing everything from manufacturing to packaging. These advanced systems combine cutting-edge automation with precise marking capabilities to increase productivity, accuracy, and traceability.

Smart cutting machines are automated devices used for high-precision cutting of materials. They are equipped with advanced software and hardware that enable them to perform complex cutting tasks with minimal human intervention.

The main functions of intelligent cutting equipment:

Material Holder

The holder is a simple device located at the front of the cutter to collect loose cut material. It helps to quickly separate finished product from waste material.

Precision Welded Frame

The frame of the cutter is manufactured to heavy-duty industrial standards. The assembly process includes pre-welding, machine welding and post-welding heat sealing, and is subject to strict quality control to create the strongest and most durable frame.

Linear Guides

Linear guides provide extremely low-friction movement and are able to withstand loads in all directions. This feature allows for high accuracy and greatly improves movement precision.

Conveyor Feeding System

The cutting mat is a belt that forms a closed loop around a pulley so it can rotate continuously, allowing for continuous automatic feeding and essentially unlimited cutting length.

6-Zone Vacuum Bed

The industrial-grade aluminum honeycomb vacuum tabletop is equipped with an independent 6-zone vacuum system to ensure perfect flatness for all media types. The conveyor belt is made of durable 4mm thick felt, which is breathable, wear-resistant and has a long service life. The tabletop is equipped with a powerful vacuum pump that provides excellent downward pressure to ensure that it will not move during operation.

Inkjet Marking Capability

Smart cutting machines equipped with inkjet marking can perform cutting and marking tasks simultaneously. This dual functionality ensures that each cut piece is accurately labeled or marked as needed. The integration allows for a high level of customization. Manufacturers can easily change the marking to include different text, logos, or barcodes without the need for additional setup or equipment. This flexibility is particularly beneficial in short-run production and prototyping.

Cross-Industry Applications

The versatility of smart cutting machines with inkjet marking makes them a valuable asset across a variety of industries

How does the inkjet marking function of the smart cutting machine work? Please watch the video below!

Smart cutting machines with inkjet marking represent a major leap forward in industrial automation. By combining precision cutting with flexible marking capabilities, these machines streamline production processes and reduce costs. As the technology continues to develop, their impact on various fields will only grow, making them an indispensable tool in the pursuit of higher productivity and quality.

This article ends here. If you want to know more, please contact us for more information. You can also learn more and contact us through the following methods!

For more information, please consult:

Email: [email protected]

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://aollaser.net/