For enthusiasts and professionals in the automotive interior industry, the appeal of precision-cut parts is undeniable. From the smooth lines of dashboard elements to the perfect fit of the interior, cut quality can determine the beauty and functionality of your car’s interior. However, this level of accuracy comes at a cost. So why is a machine capable of such fine work, such as a digital cutting machine, considered so valuable despite being expensive?

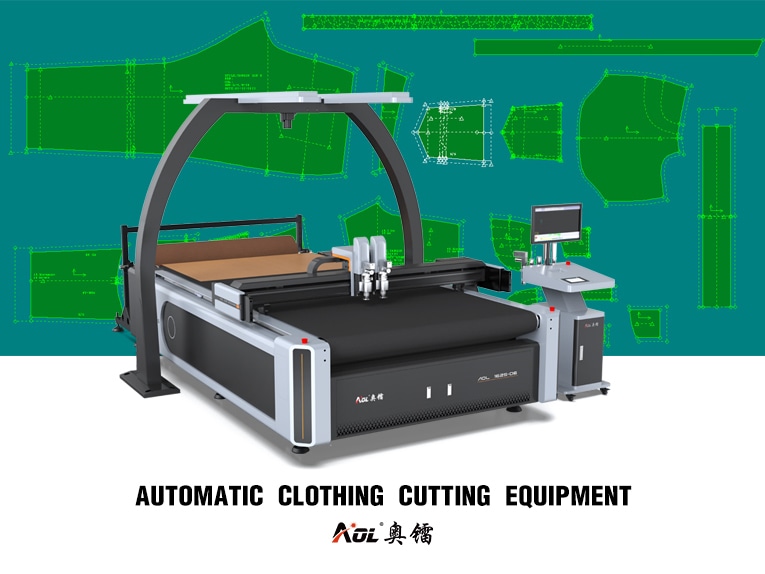

These machines are designed with the unique needs of automotive interiors in mind, which require not only precision but also the ability to handle materials ranging from leather to composite fabrics. Their high cost is justified because they are durable, technologically advanced, and bring unparalleled quality to car interiors.

Is the investment in precision cutting of automotive interiors worth it?

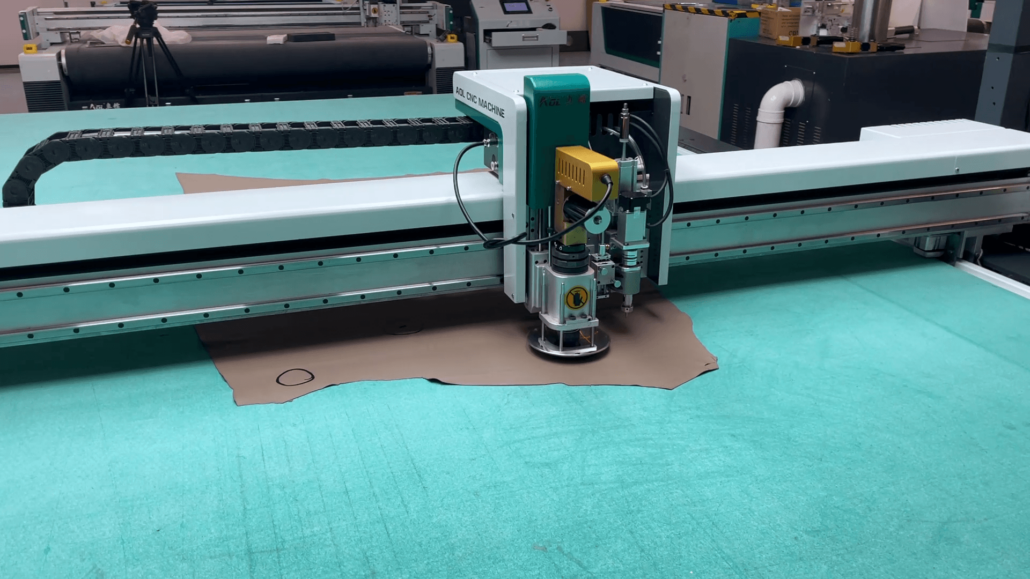

In the competitive world of automotive design and manufacturing, advantage often lies in the details. Digital knife cutting technology enables manufacturers to achieve unparalleled precision when cutting interior materials, enhancing the appeal and comfort of the final product. Investment in such technology, while significant, opens up new avenues for innovation and customization of automotive interiors, making it a compelling option for companies aiming to differentiate their products.

Selecting machines capable of handling the specific materials used in automotive interiors and integrating them efficiently into the production line can significantly improve product quality and reduce waste, providing a significant return on investment over time.

Driven by consumer demand for personalization and luxury, the automotive interiors industry is shifting toward greater customization and higher quality standards. Traditional cutting methods, while effective for mass production, often fail to meet these new expectations. Digital knife cutting technology, capable of producing complex designs quickly and accurately, is becoming indispensable for manufacturers who want to stay ahead of the curve.

However, as home and mobile entertainment options become more advanced, the automotive industry must continue to innovate to keep vehicle interiors attractive and functional, which challenges traditional manufacturing methods.

Why some auto interior manufacturers are hesitant

Despite the obvious benefits, some manufacturers are hesitant to invest in advanced cutting technology due to high upfront costs and the need for specialized operator training. Additionally, the rapid pace of technological advancement can make it difficult for companies to time their investments because they worry that their technology may soon become obsolete.

The unique advantages of precision cutting in the field of automotive interiors

Digital knife cutting technology is unique in the automotive interior industry in its ability to transform high-quality materials into precision-cut parts that perfectly fit the vehicle design. The technology supports the trend towards more personalized and luxurious car interiors, providing manufacturers with the flexibility to innovate and meet personal preferences. The tactile and visual appeal of perfectly cut materials can significantly enhance the overall driving experience, signaling a shift from standardization to a more customized approach.

Precision cutting machine pricing reflects the sophistication of the technology and the quality of the parts produced. High-grade materials require equally high-grade cutting solutions to maintain their integrity and beauty. Customization options allow manufacturers to customize the cutting process to specific materials and designs, which also adds to the cost. However, this investment is crucial to achieving the level of detail and quality expected in modern automotive interiors.

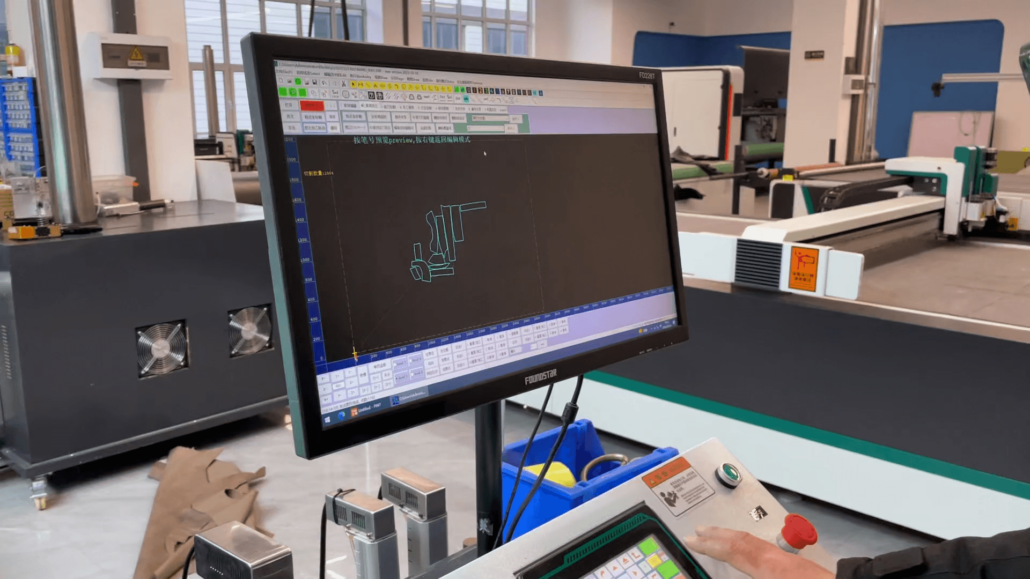

The role of software and licensing in cutting technology

Software plays a vital role in precision cutting, enabling complex designs and customization options that make car interiors unique. Licensing fees for software and design patents add to costs but are critical to accessing cutting-edge technology and designs. These ongoing costs ensure that manufacturers can continue to produce interiors that meet the highest standards of quality and innovation.

In summary, the high cost of precision cutting technology in the automotive interior industry proves the value it brings. As manufacturers strive to meet the growing demand for personalized and luxurious vehicle interiors, investment in such technology is not only justified but essential. The ability to create interiors that resonate with consumers on a personal level can set a brand apart, making precision cutting technology a cornerstone of modern automotive interior manufacturing.

For more information, please consult:

Email: [email protected]

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://aollaser.net/