CNC fabric cutting machines are widely used in the cutting of sofa fabrics, making the cutting of sofa fabrics change from traditional manual cutting to automatic cutting. Automatic cutting is the trend of sofa fabric cutting.

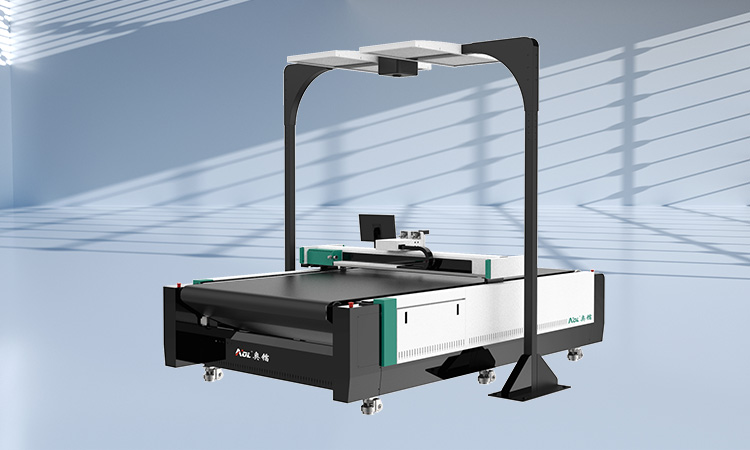

Digital fabric cutting machine is a fully automatic industrial CNC cutting system, suitable for fabrics, textiles, leather, carpets, floor mats, leather seat cushions, inner linings, trunk mats, car seat cushions, car interiors, and can also cut sponges , EVA, soft glass, silicone, rubber, etc. Digital precision cloth cutting machines are widely used in clothing, shoe materials, furniture, sporting goods, packaging, home textiles, decorations, automobiles and other industries. This digital cloth cutting machine is also called CNC cloth cutting machine, industrial cloth cutting machine, digital cloth cutting system, digital cloth cutting machine, precision cloth cutting machine, digital leather cutting machine, digital textile cutting machine, industrial leather cutting machine, Industrial textile cutting machine.

What is the working principle of CNC cloth cutting machine?

A CNC fabric cutting machine can complete the die-cutting, creasing and forming of leather, cloth, paper, rubber and other flexible materials without molds, which can save a lot of manpower, molds and die-cutting machine costs. It can also create a set of standardized and feasible complete solutions to meet customers’ production goals of small batches, multiple orders, and multiple styles.

Mainly through computer graphics, the internal data is processed and then transmitted to the machine control card. The control card then sends a command pulse signal to the servo drive. The drive drives the servo motor to move to achieve the movement of the machine, and at the same time sends a signal to the cutting tool to process the raw materials. Precise cutting action.

The fully automatic CNC cloth cutting machine has high precision and high efficiency, and is suitable for the manufacture of small batches of fabrics. The automatic cloth cutting machine can cut any shape, the cutting edge is smooth, no pollution, no smell, and environmental protection.

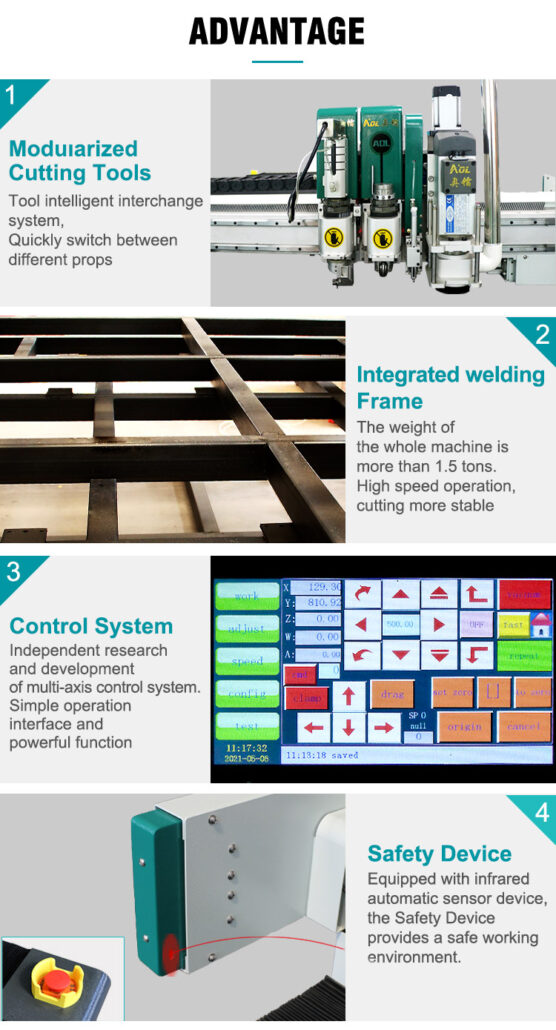

Advantages of automatic CNC fabric cutting machine:

1. High speed and high quality, its cutting speed is 5-8 times faster than laser cutting machine.

2. Advanced computer numerical control system, easy to operate with Ethernet port.

3. Cutting without air pollution, no burning edge, uniform color.

4. This machine cuts soft materials with perfect edges and corners.

5. The CNC cloth cutting machine adopts Japanese Panasonic servo motor and driver, with fast cutting speed and high precision.

6. This machine can be equipped with different cutting tools to meet various needs.

7. Special safety sensor device, in line with European standards.

Features of CNC fabric cutting machine:

1. Equipped with an intelligent cutting head, the cutter can be replaced according to the needs, and various gaskets can be effectively cut, with strong practicability.

2. All electrical components and pneumatic components adopt well-known brand products to ensure the stability and reliability of the long-term use of the whole machine. the

3. The cutting precision of the equipment is high, and the error is extremely small, which meets the strict requirements of gasket production for precision.

4. Pneumatic knife cutting, the cutting surface is smooth and round, no secondary processing is required, it can be used directly, reducing the production process and improving production efficiency.

5. The cutting accuracy of this machine is 0.01mm, the reset accuracy is 0.01mm, the product error is ±0.03mm, the cutting surface finish can be achieved, and the multi-cavity waste can be greatly saved.

6. Cutting products are vacuum-adsorbed to make the finished product more precise.

7. Optional automatic feeding device can realize continuous feeding, realize large-span cutting, unlimited theoretical cutting length, improve production efficiency, and have a high degree of automation.

8. Various cutting tools can be selected according to the product requirements of customers.

Matters needing attention when using CNC fabric cutting machine:

1. Turn on the air pump before turning on the machine every day, then turn on the computer and software, and then turn on the control box. After use, please turn off the power in order, first turn off the air compressor, computer, vacuum pump, and finally turn off the equipment and air valve switch.

2. The dirt on the machine tool and guide rails must be cleaned on working days to keep the bed clean.

3. If you leave the machine for a long time, please turn off the power to prevent unnecessary damage caused by non-professional operation.

4. Thoroughly clean the machine every week, clean the horizontal and vertical guide rails, drive gears and racks, and add lubricating oil.

AOL intelligent blade cutting machine has high precision and high efficiency. Our professional after-sales service can provide automatic cutting solutions for various industries.

For more information, please consult:

Email: [email protected]

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://aollaser.net/