Inflatable rubber boats are commonly known as inflatable boats. Most of these boats are made of rubber, so they also become rubber boats. Uninflated can be compressed, can be used for recreational competitions and water rescue and other purposes, and is also widely used by marines in various countries. Before the inflatable rubber boat is not formed, the rubber material needs to be cut first, and then the subsequent finished product production is carried out. At present, the commonly used cutting methods are manual cutting and intelligent cutting. Due to the current new crown virus, manufacturers face high labor costs and low efficiency. Therefore, most manufacturers use intelligent cutting. Now I will introduce a smart device – inflatable rubber boat rubber cutting machine!

How does an Inflatable rubber boat cutting machine work?

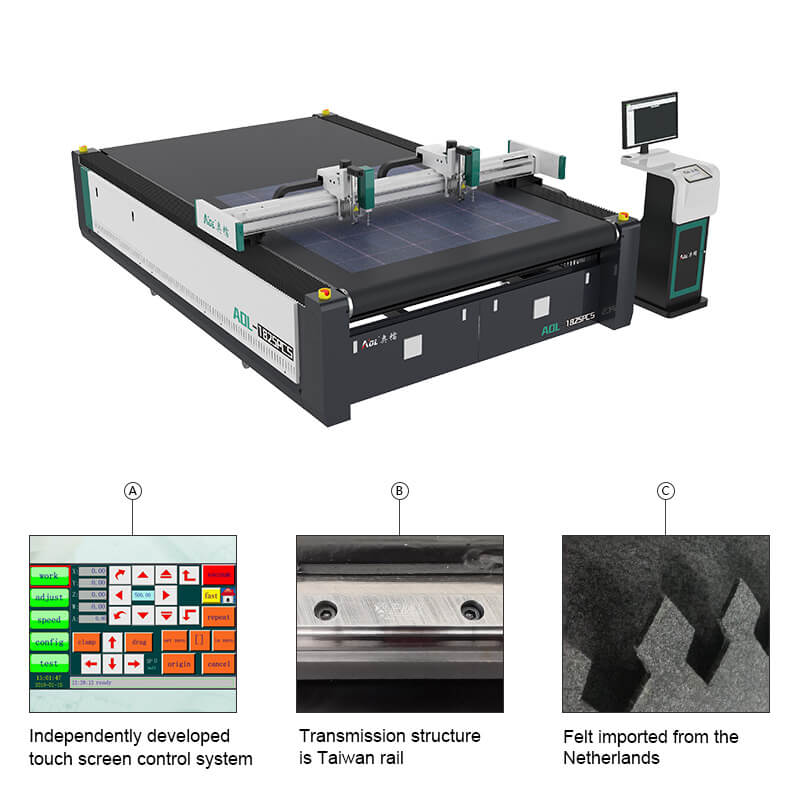

The machine uses computer graphics, and transmits it to the machine control card through internal data processing. The control card sends command pulse signals to the servo drive. The drive drives the servo motor to move to achieve the movement of the machine, and at the same time sends signals to the cutting tool. Do the cutting action.

The inflatable rubber boat cutting machine adopts the cold cutting process, the characteristics of environmental protection and no pollution are the reasons why many manufacturers choose it, and the cutting edge is smooth and free of burrs.

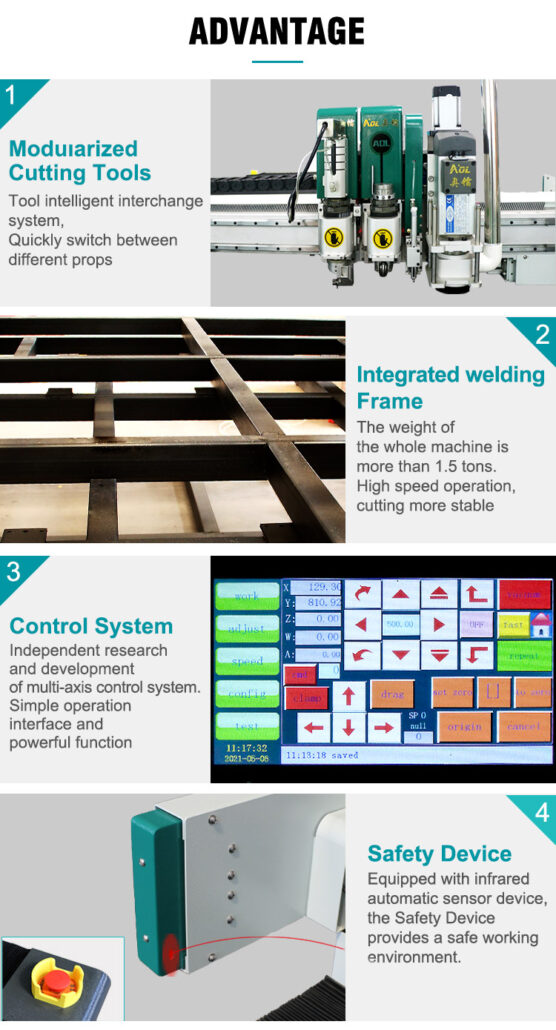

Intelligent typesetting and cutting can save materials by more than 30%, which solves the shortcomings of manual cutting of waste.

The machine is equipped with an infrared sensor safety device, which maximizes the safety of the workers and avoids the loss of cutting materials.

Please click on the left

Many people are very satisfied after consulting our machine, but they feel that the price is too expensive and hesitate. Now I will lead you to make a calculation, and you will know how much benefit it will bring you by using our cutting opportunity.

1. The work efficiency of using a machine cutting machine to work a day is equivalent to the workload of 4-6 employees, and it can save more than 30% of raw materials. This day, only one person can simply operate the machine to complete the cutting, but from manual labor If you calculate the cost and material cost, you can save hundreds of dollars in one day, several thousand dollars in a month, and then in a year?

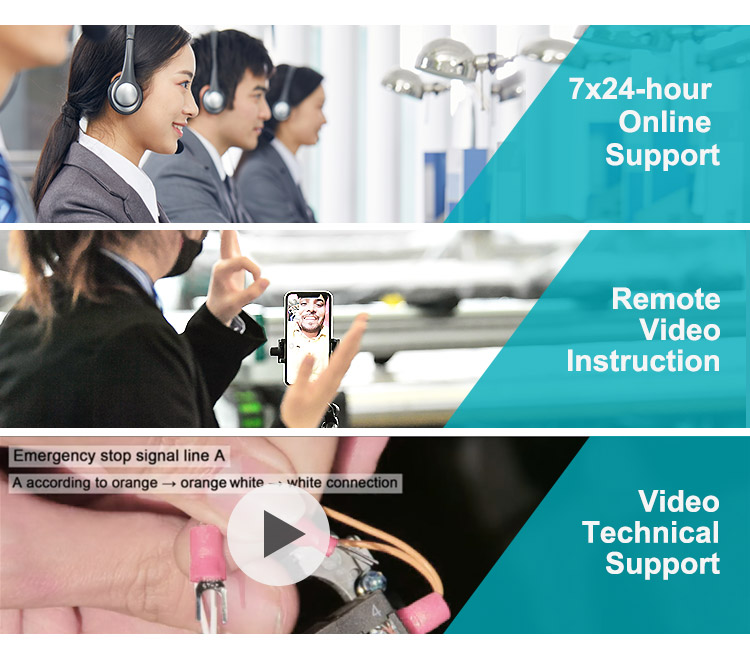

2. In addition to the price, many manufacturers are also concerned about after-sales problems. For after-sales problems, I think you can rest assured. Our company’s after-sales team has more than 20 engineers, and they can speak English. At least three engineers serve one. A customer/agent who can provide remote assistance to help you install and use your equipment, and one item that only we have, and currently no other company, is that we will set up a dedicated service team for you, including AOL sales staff, AOL engineers, AOL sales managers, AOL sales directors and you (or your employees), if you have any questions, we will respond within 1 minute. So what are you still worried about?

3. Most other companies promise a one-year machine warranty service, but only our company has a three-year warranty service. Except for felts, knives, and blades, if there is any problem during this period, we will replace them with new ones for free through DHL. Free maintenance within the year. And we guarantee replacement parts will be shipped within 24 hours. Regarding the software, we upgrade for free for life. Have you not been excited when you see it?

4. The accessories of our equipment are all imported brands, not imported is necessarily good, but after more than ten years of experience in accessories brand selection, we only choose the best quality accessories, so as to make the best quality. machine, consumers can also get a machine that is durable and has a real sense of maximizing savings. Before the equipment leaves the factory, it has to undergo 72 hours of uninterrupted high-load proofing and trial cutting, so that customers who receive the machine can use it comfortably, with fewer quality problems, and our staff can have sufficient time to develop more in-depth content. Isn’t it the best of both worlds for us and our customers?

So what do you mean by expensive? The price is low, there is no effect, you are disappointed, this is expensive!

What do you mean by cheap? With the effect, it can solve your problem and make you satisfied, this is called cheap!

The above introduces our machines through price, after-sales, guarantee and quality. I believe you must have your own ideas. If there is anything you don’t understand or not mentioned in the above article, please contact us, we will There are big bosses who have been in the industry for more than ten years to answer you in person and relieve all your questions!

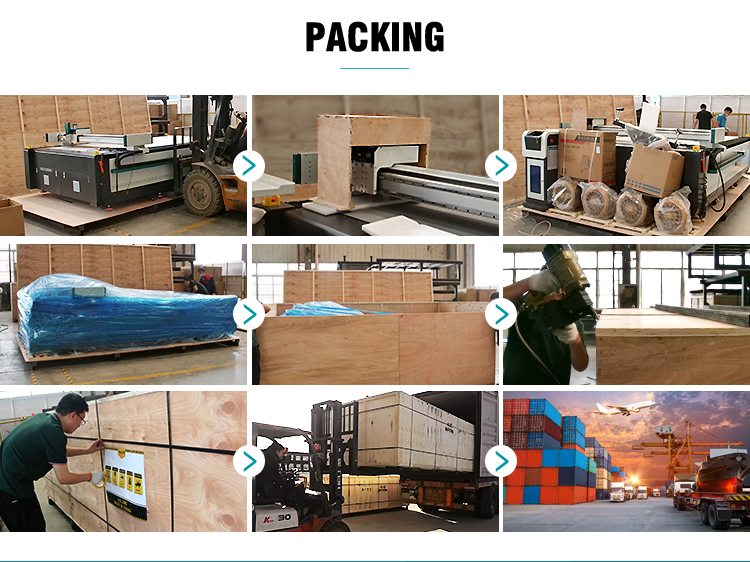

Packaging of Inflatable rubber boat cutting machine:

1. Outer packing: Standard sea export plywood box.

2. Inner packing: stretchable film and plastic film to prevent moisture.

If you have special requirements, we can negotiate amicably.

In addition to cutting rubber, our machines can also cut materials such as leather, advertising packaging, carpet industry, textile industry, composite material cutting, and automotive interior trim, and are suitable for processing and cutting various flexible materials. The maximum utilization of the machine can be achieved. What are you waiting for, get in touch with us now!

AOL intelligent blade cutting machine has high precision and high efficiency. Our professional after-sales service can provide automatic cutting solutions for various industries.

For more information, please consult:

Email: [email protected]

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://aollaser.net/