BOPP film is a very important flexible packaging material

BOPP film is colorless, odorless, odorless, non-toxic, and has high tensile strength, impact strength, rigidity, toughness and good transparency.

BOPP film cutting problem

We recommend using a blade cutter to cut BOPP film. On the basis of ensuring the cutting quality, the automatic BOPP film cutter adds automatic feeding and receiving, which can also reduce labor costs.

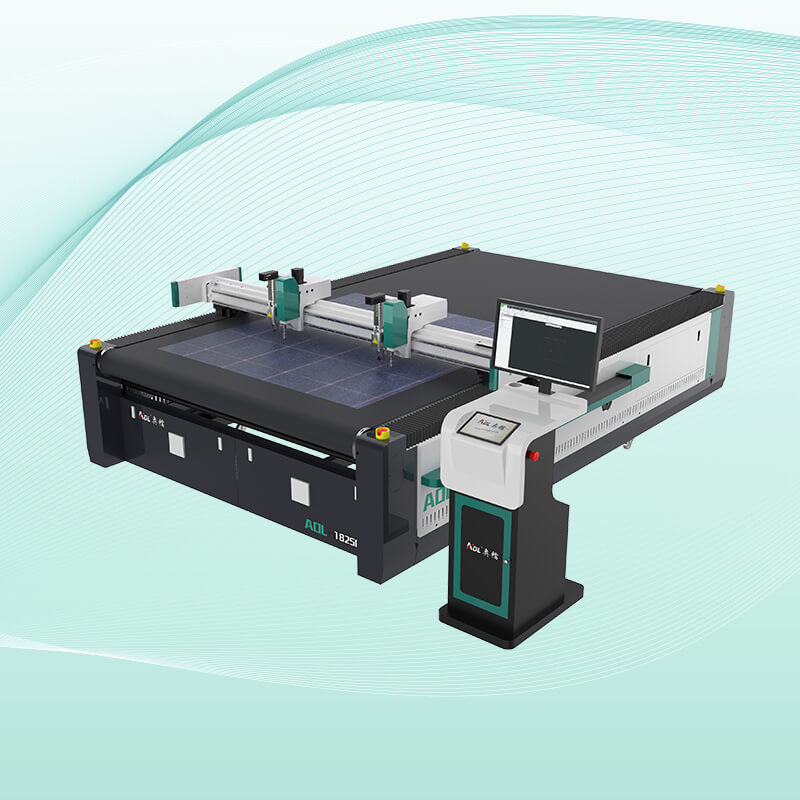

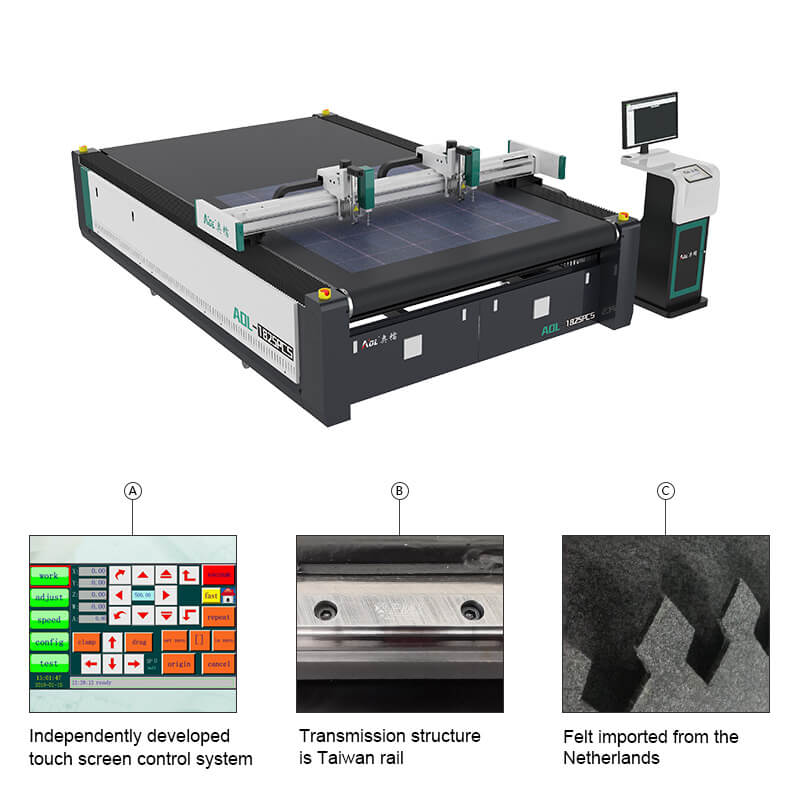

AOL automatic BOPP film cutting machine

1. AOLCUT self-developed software can be imported with one key, and ordinary workers can work proficiently within 2 hours

2. Use Taiwan linear guide rail drive system with accuracy ±0.1mm

3. AOL rapid tool exchange system provides a variety of cutting tool options for various materials

4. Super nesting software, material utilization rate increased by more than 10%

5. Select Japanese Panasonic servo system to increase production efficiency by more than five times

6. Automatic pulling and unloading, saving time, effort and more environmental protection

7. The anti-static system of the whole machine to maximize the protection of personnel safety

8. Professional R&D team can provide assembly line supporting plan

9. This model has won 6 patented technology certifications at home and abroad

Company Info