There are two types of leather. One is compound leather. One is genuine leather. Today we only introduce how to cut genuine leather.

The leather cutting process is as follows:

- Mark defects. 95% of leather is flawed. So you should mark every defect for easy inspection and identification.

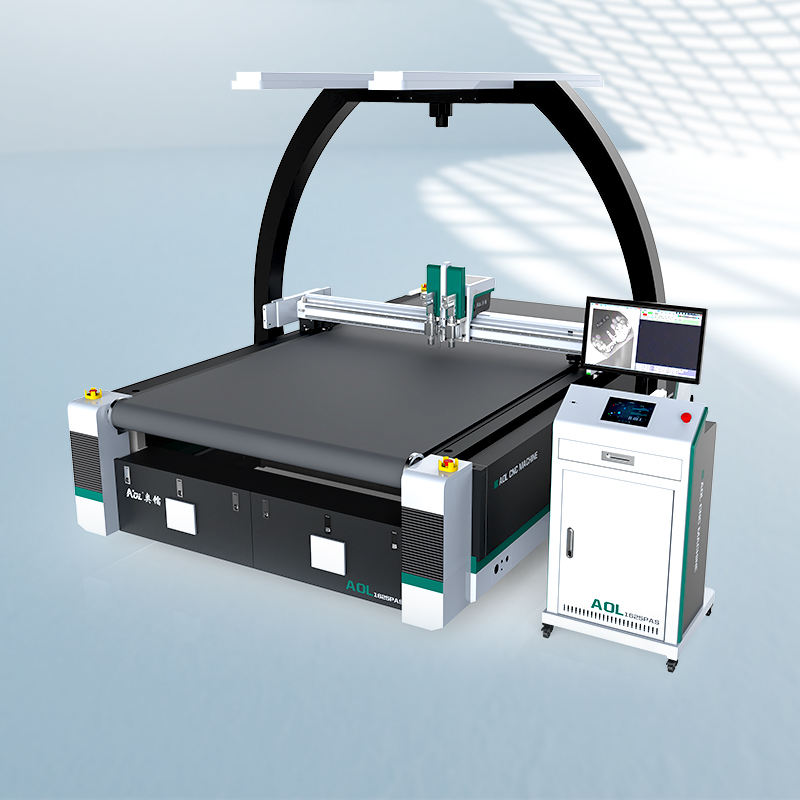

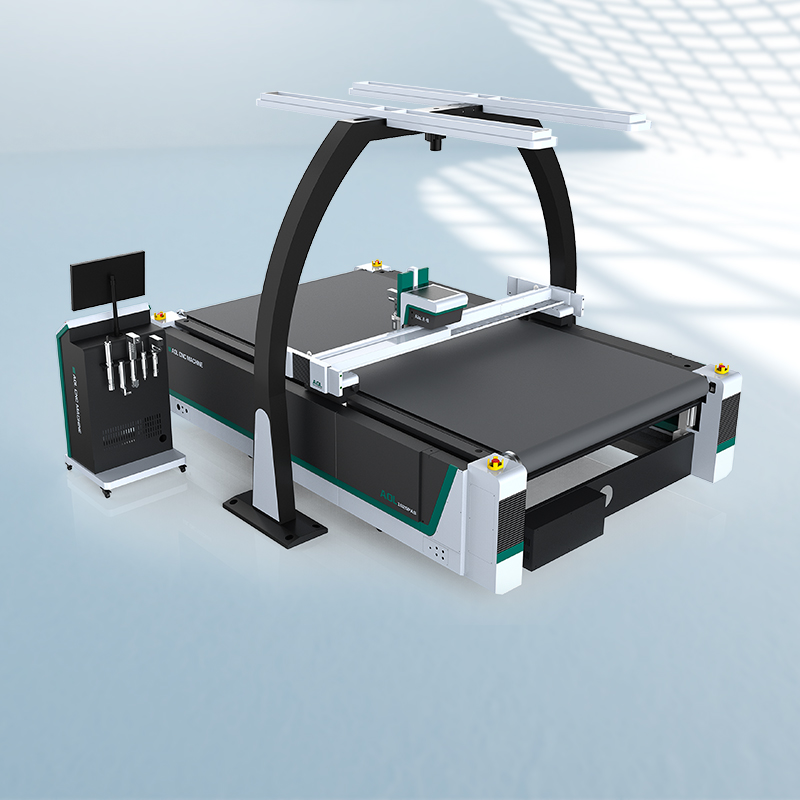

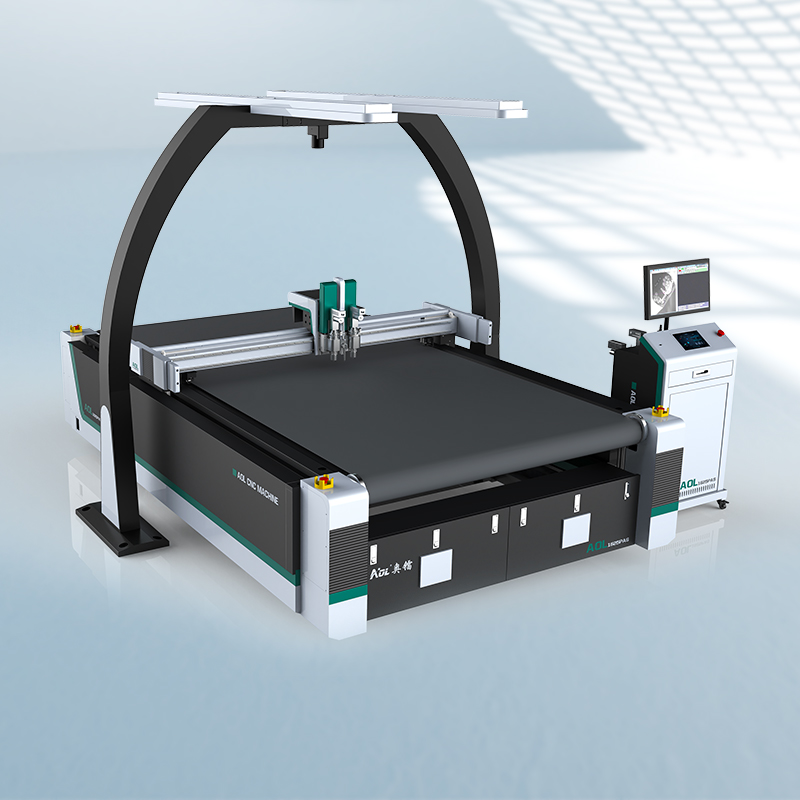

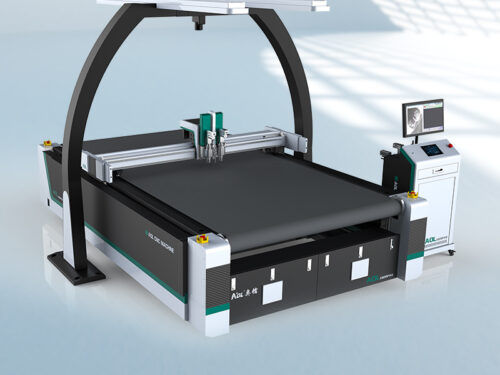

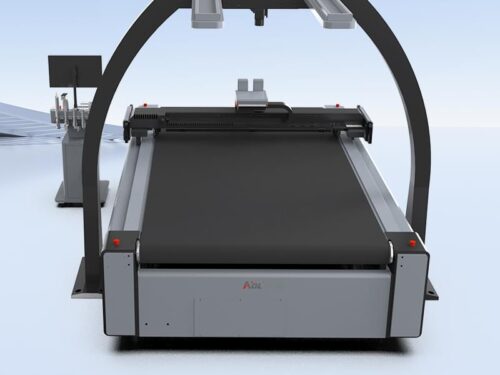

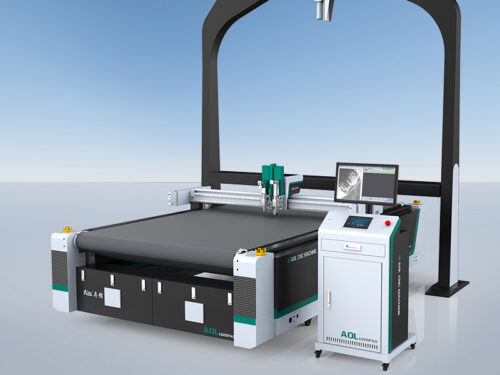

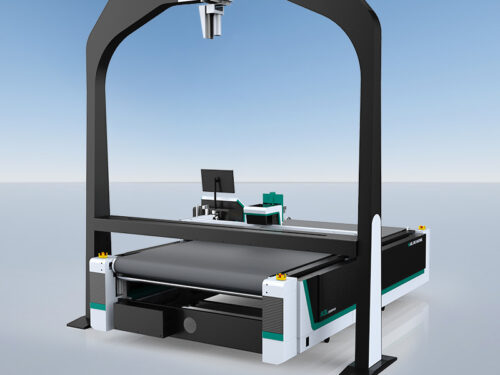

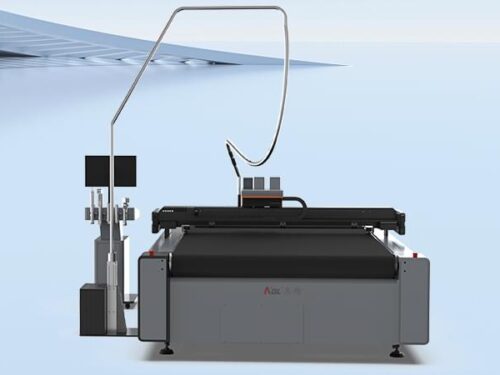

- The software automatically typesetting. There are digital cameras and projectors on the machine.

The function of the digital camera is to automatically identify defects and leather outlines (previously manually marked defects), and then the system can automatically typeset according to the shape of each piece of leather, of course you can typeset manually. But we recommend using our typesetting software for two reasons. One: Improve material utilization and avoid waste. Two: The materials are generally more expensive, which saves the cost of raw materials.

The function of the projector is to allow you to visually see the cutting graphics and typesetting, avoiding the deviation of the cutting position.

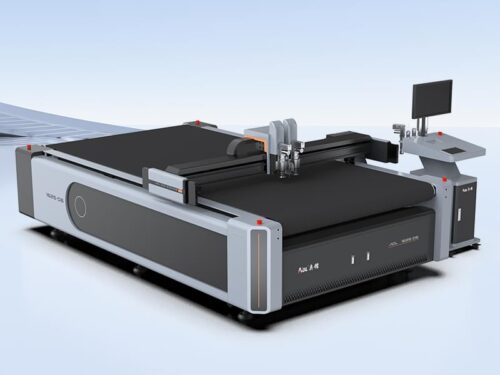

Their joint efforts will increase the efficiency of the machine. - The machine automatically cuts and feeds. After finishing the layout, you can enter the cutting process. Most of the leather is cut with a swing knife cutting head, which cuts quickly and accurately. One machine can replace 3-4 labor.

.jpg)

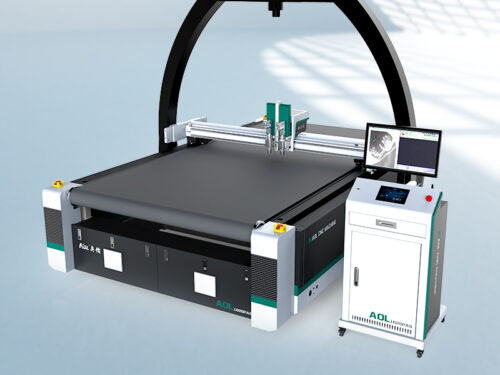

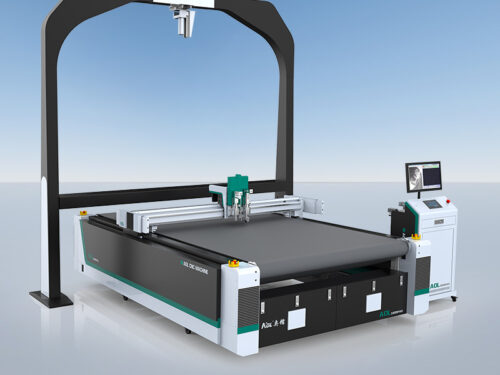

| Technical parameters | AOL-1625, AOL-1825 |

|---|---|

| Effective working area | 1600*2500MM, 1800*2500MM |

| Multi-function cutting head | The combination of Multi-function cutting head and holders, be with full cut, kisscut, creasing wheel,v-cut and laser red light positioning functions, CCD positioning, Camera extract large contour to cut |

| Tools | Universal Drawing Tool, Creasing Wheel Tool |

| Moving speed | 800-1500mm/s |

| Repeat precIsion | ±0.05mm |

| Interface | Enternet port |

| Control panel | LCD touch screen |

| Drive system | Imported servo motor, linear guid, synchronous belt, screw |

| Cutting material | Knitting, woven, fur (sheep shearing), PU leather, oxford cloth, canvas, sponge, imitation leather, cotton linen, blended fabric etc. All kinds of clothing, bags, sofa fabrics and carpet fabric etc |

| Instruction system | HP- GL Compatible format |

| Rated power | 2. 2KW |

| Rated voltage | 220V |

| Cutting thickness | ≤50mm(According to different material) |

| Material fixed way | Vacuum adsorption |

| Auto feeding system | Acuum sucker adsorpting sheet |

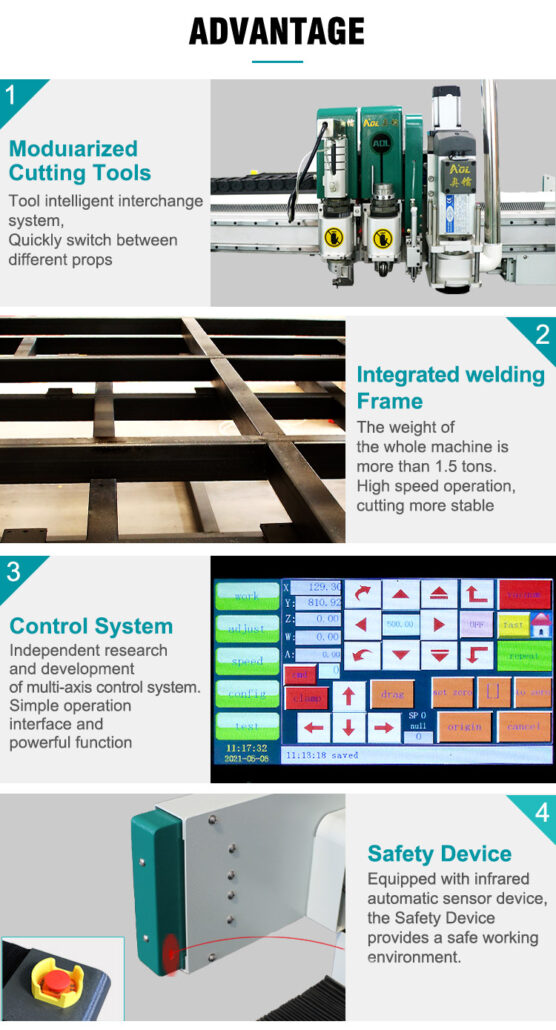

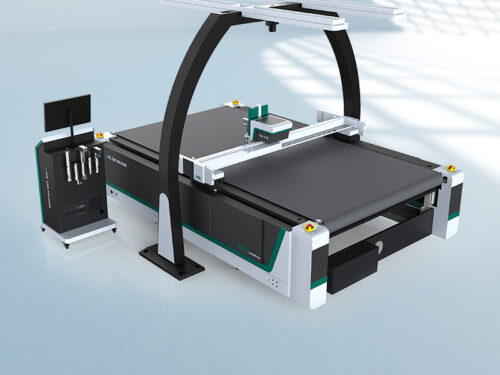

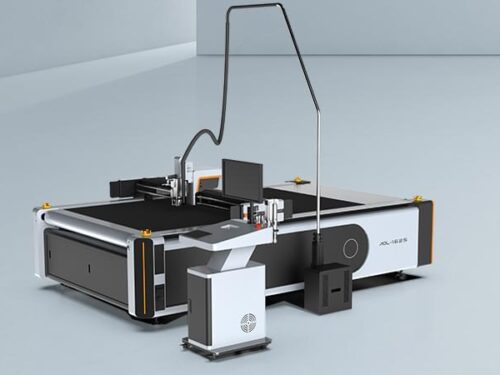

Advantage of automatic leather cutting machine

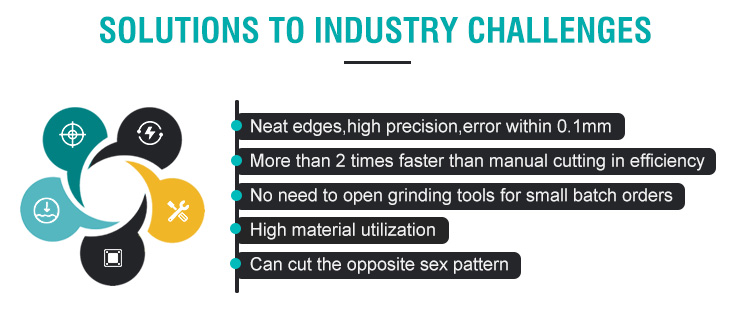

1. The platform detection device regulates the knife pressure automatically, enabling a level platform and perfect cutting.

2. The high precision CNC oscillating knife leather cutting machine can induce draft separately and easily cuts small pieces.

3. The anti-collision and the built-in auto-sensing devices ensure the security of cnc oscillating knife leather cutting machine.

4. High efficiency can be realized without making a high-cost knife model.

5. The high precision CNC oscillating knife leather cutting machine is designed for production with small quantities and can save on costs while maintaining speed and accuracy.

Why Choose Plastic Composite Mat Board Cutting Machine

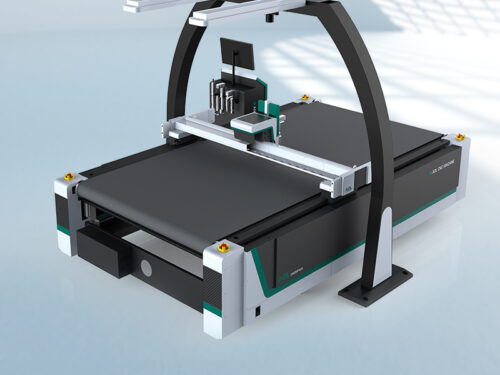

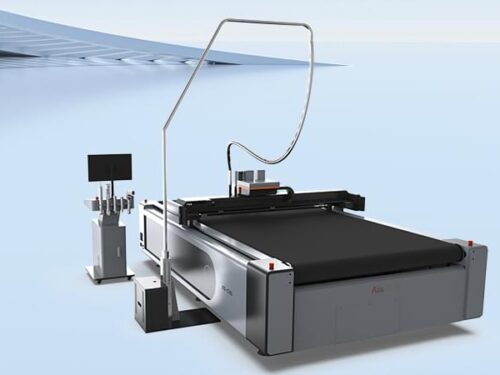

Why choose to cooperate with AOL cnc:

1. The platform detection device regulates the knife pressure automatically, enabling a level platform and perfect cutting.

2. The high precision CNC oscillating knife leather cutting machine can induce draft separately and easily cuts small pieces.

3. The anti-collision and the built-in auto-sensing devices ensure the security of cnc oscillating knife leather cutting machine.

4. High efficiency can be realized without making a high-cost knife model.

5. The high precision CNC oscillating knife leather cutting machine is designed for production with small quantities and can save on costs while maintaining speed and accuracy.

About AOL

AOL is one of the famous professional automatic leather knife cutting machine manufacturers and suppliers in China,cnc leather cutting machine price is right.If you need it,welcome to contact us!

Guarantee & after-sales service

FAQ

1. Are you a trading company or a factory?

We are manufacturers.

2. When can we arrange shipment?

We usually arrange shipment within 15 days after getting deposit, but customized machines should be more than 25 days.

3. Do you provide equipment operation training after sale?

Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. All of our engineers have passport.

4. Can you customize the machine according to my request?

Yes. We have experienced engineers and technical team, can provide personalized service.

Service support of AOL cutting machine

1.Three-year warranty service. Except for wearing parts (blades, knives, felts, vacuum pumps, etc.), other major parts will be repaired free of charge if there are problems during the warranty period.

2.Lifetime free service

3.Software lifetime Free upgrade

oscillating knife cutting machine for leather industry also have CNC Leather Cutting Machine, Digital Leather Cutting Machine, Automatic Leather Cutting Machine

The price of CNC knife cutting machine, Please inquire and tell us your cutting material and size.

If you want to know the price of the digital leather cutting machine, please send us the name, size and thickness of the material to be cut, so as to give you the most detailed quotation.

More autimatic leather cutter machine for sale, welcome to visit https://www.aollaser.net/

MESSAGE

CONTACT

No. 1777 Chunhui Road, Licheng District, Jinan City, Shandong Province, China

No. 1777 Chunhui Road, Licheng District, Jinan City, Shandong Province, China

+86-531-88620680

+86-531-88620680

0086-18560162709

0086-18560162709

+86-531-88620680

+86-531-88620680

Reviews

There are no reviews yet.