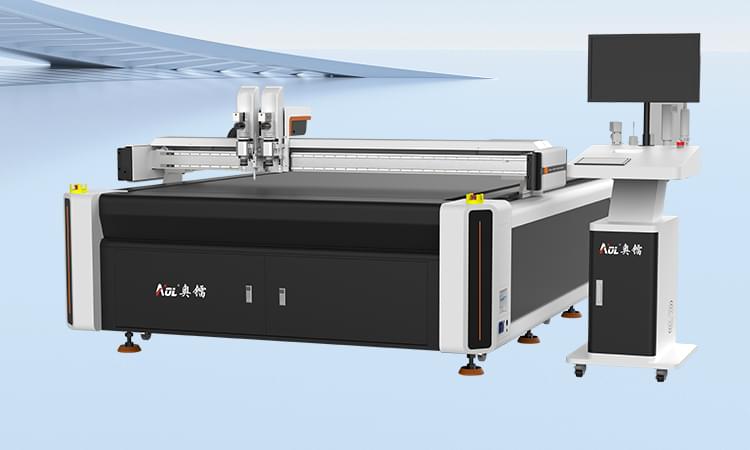

As an operations engineer for AOL CNC, I have seen firsthand how vibrating knife cutting machines have revolutionized low-volume cutting, particularly in the production of gaskets. Let me share some insights into why these machines are game-changers and how they can benefit your production process.

So what is an oscillating knife cutting machine?

I believe that users who have read our article already know it very well. Let me introduce it to you again. Simply put, it is a high-precision tool that uses a rapidly vibrating blade to cut various materials. Whether it’s rubber, silicone or foam, this machine can handle it with ease.

Key components include the high-speed swinging blade itself and the control system that ensures precise cuts. We have electric vibratory cutters for harder materials and pneumatic vibratory cutters for softer materials. It’s like having a Swiss Army Knife on your production floor, ready for any situation.

What are the advantages of small batch production of vibrating knife cutting machines?

1. No mold required

Imagine the time and money saved by not having to create molds for every new design. You can switch between different shapes and sizes on the fly. This flexibility is a dream for custom orders and low-volume production.

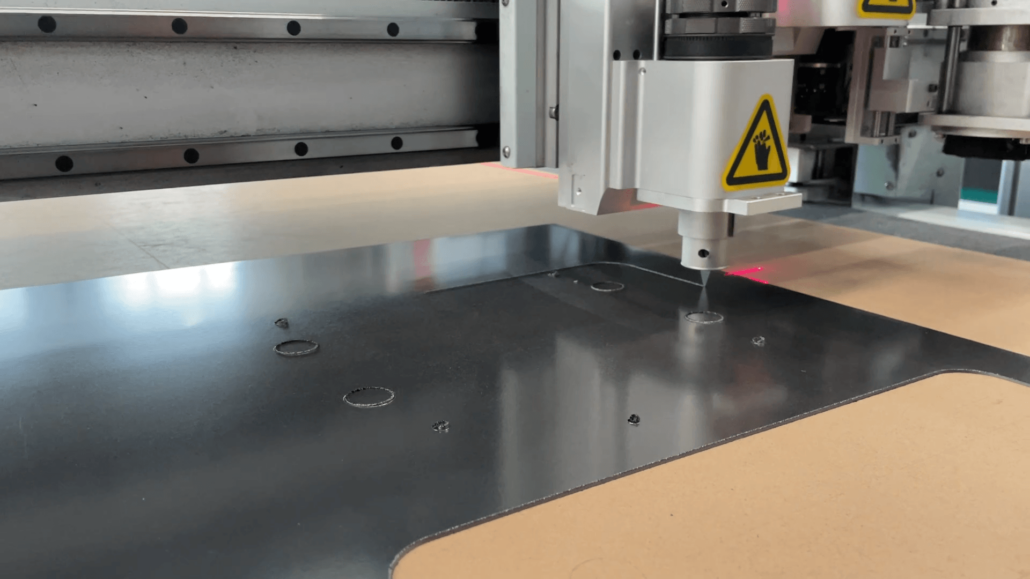

2. High precision and accuracy

Our vibrating knife cutting machines deliver high-precision, clean, accurate cuts every time. This is crucial when you’re dealing with complex designs. Consistent quality means less waste and higher customer satisfaction.

3. Versatility and flexibility

These machines can handle a wide range of materials. From rubber to foam, the vibrating knife cuts through them like butter. This versatility means you can take on different projects without the need for a different machine.

Practical applications of vibrating knife cutting machines for small batch cutting:

Mass custom gasket cutting

We have some customers who require custom gaskets in small quantities. Traditional methods are too slow and costly. With the help of our vibrating knife cutting machines, they are able to produce high-quality gaskets quickly and efficiently.

Specialty and Niche Market Products

For those niche markets where products are often unique and production volumes are limited, the flexibility of our knives is invaluable. Whether it’s custom packaging or specialty industrial parts, these machines get the job done.

Reduce setup and conversion time

Oscillating knife cutters greatly reduce setup and changeover time. This keeps your production lines running and meeting tight deadlines.

Reduce material waste

Precision cutting means less scrap. This not only saves materials, but also reduces costs. Efficient production means sustainable production.

Maintenance and operating costs

Our machines are designed for easy maintenance. Less downtime means more productivity. Additionally, the long-term cost benefits make it a smart investment for any manufacturing setup.

Oscillating knife cutting machines are changing low-volume production. Their flexibility, precision and efficiency make them an indispensable tool for modern production lines. If you’re looking to improve your manufacturing process, consider adding a vibrating cutter to your arsenal.

Interested in learning more or seeing our machines in action? Please contact AOL CNC and we are here to help you take your production to the next level.

By leveraging the flexibility and efficiency of an oscillating knife cutting machine, you can streamline production and meet the demands of today’s fast-paced, customization-driven market.