Creasing, slotting and notching are several common processes in carton forming. With the increasing requirements of the commodity market for product packaging quality, efficient, flexible and stable CNC cutting machines will surely become the first choice.

According to the design requirements of the product, the cutting machine drives the cutter head to creasing or slotting according to the path preset by the system, and then cuts out the shape, so that the cardboard material is bent and shaped according to the predetermined position, becoming the common carton shape in our daily life.

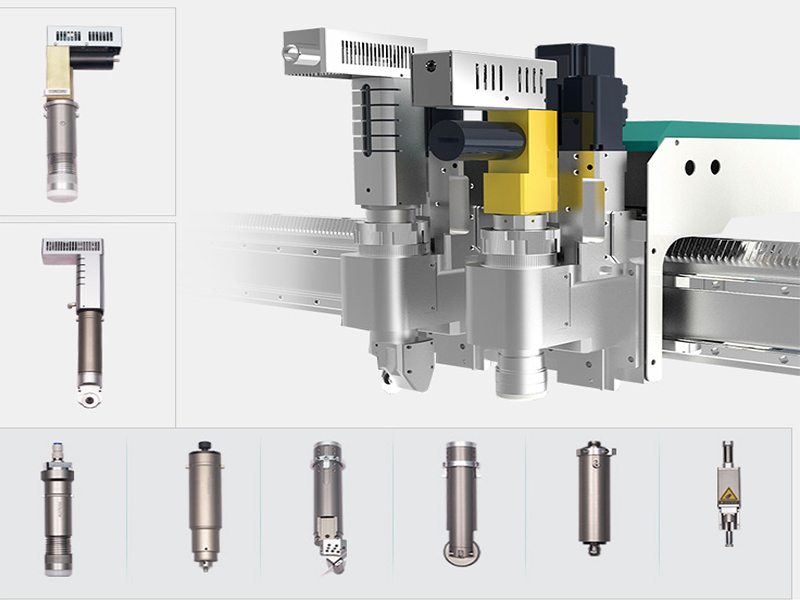

The “pressing wheel + vibrating knife” and “bevel knife + vibrating knife” of the AOL carton packaging forming intelligent digital cutting machine are now widely used cutting tools in packaging design and processing. Let’s take a look! For thin corrugated cardboard, you can choose to use “vibrating knife + pressing wheel!” The round wheel of the pressing wheel rolls over the material to form an indentation effect on the material, and then the vibrating knife cuts out a full outline.

For thick vertical corrugated cardboard and high-density gray cardboard, you can choose “vibrating cutter + bevel knife”. The bevel knife can process V-grooves and bevels of different specifications, and then the vibrating knife can cut out the packaging outline.

Working principle of the vibration knife cutting tool: The vibration knife drives the blade up and down with a high frequency vibration through a motor to achieve rapid cutting of the material. It is particularly suitable for cutting and shaping medium-density materials. Different blades can be used to process different materials.

Working principle of the creasing wheel: The round wheel of the creasing wheel rolls on the material to produce a creasing effect on the material. The knife holder of the creasing wheel can clamp different wheels and support “different roller sizes”. Different creasing effects can be achieved with wheels of different sizes.

Working principle of the V-groove/bevel cutting tool: The bevel cutting tool processes V-grooves and bevels of different sizes by changing the installation angle of the blade (0°, 15°, 22.5°, 30°, 45°). The bevel cutter is clamped by the knife holder and fixed on the bracket. It can move left and right and up and down to quickly and accurately adjust the slotting position and depth.

Advantages of carton packaging forming and cutting machine:

1. The pressing wheel, beveling knife and vibration knife cooperate with each other. The pressing wheel presses out the folding crease, the beveling knife cuts the V-groove, and the vibration knife cuts the contour line. The processing speed is fast, and a large area of material can be processed in a short time, with high efficiency, suitable for mass production.

2. The indentation, grooving and planing are highly accurate. The processing is carried out according to the path given by the system, and precise movements are achieved for complex shapes, with good results, improving product quality and competitiveness.

3. The vibration knife has a wide range of options, with different powers, different amplitudes, and different speeds. The beveling knife has a wide range of options, such as single bevel, double bevel, vibration bevel, etc.; the pressure head tool holder supports “different roller sizes”, the edge of the pressure head has a certain hardness, the indentation is clear, and the quality is good

4.The knife head is made of high-quality alloy, which is durable and not easy to deform, has good operation stability and long service life

AOL intelligent blade cutting machine has high precision and high efficiency. Our professional after-sales service can provide automatic cutting solutions for various industries.

For more information, please consult:

Email: [email protected]

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://aollaser.net/