In a world of rapid technological advancement, it takes special significance to uphold the traditions that have shaped our history. Leather shoemaking is a precious handicraft that has been integrated into our lives. Think of the skilled hands that carefully shape the leather, the rich aroma of tanned leather, and the enduring elegance of a well-crafted shoe—all elements that bring a sense of nostalgia and an appreciation for an art passed down from generation to generation.

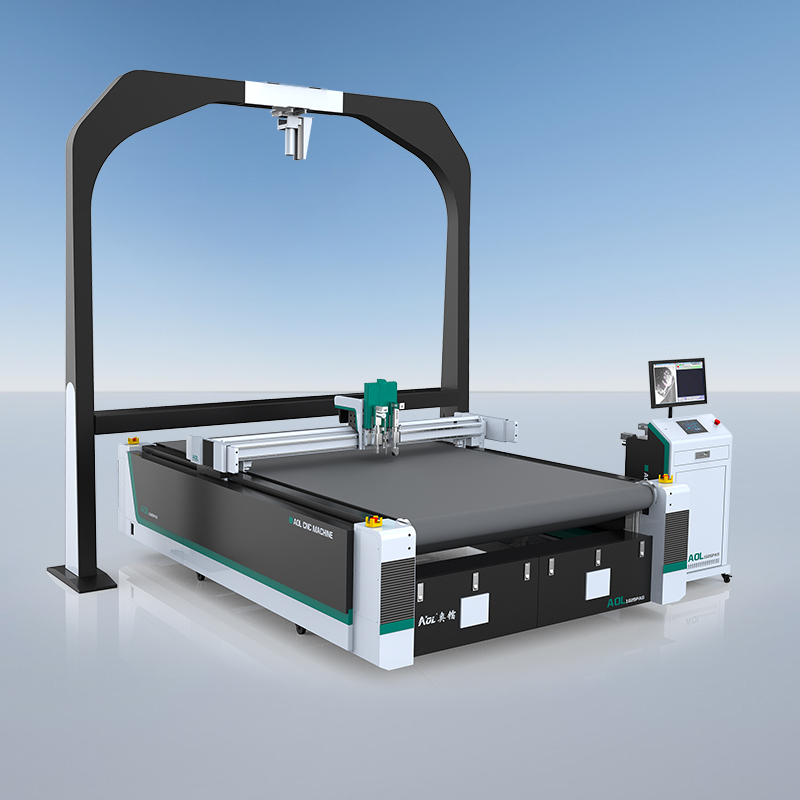

The world of leather shoemaking is undergoing a remarkable transformation – the intersection of digital precision and timeless craftsmanship. That fascinating fusion is the CNC (Computer Numerically Controlled) leather cutter, the power to reshape not only the way we make leather shoes, but also the way we imagine possibilities.

As we dug deeper into the intertwined worlds of CNC cutting machines and leather shoe manufacturing, we discovered a fascinating story – one where art and science, tradition and innovation come together. The technical nuances of the technology, its astonishing impact on design possibilities, and its elegant combination of digital precision and age-old craftsmanship invite us on a voyage of discovery. Join us as we uncover the layers of transformation and step into a revolution that bridges the gap between past and future. The curtain has opened, the spotlight is heating up, and the story of the integration of digital precision and traditional craftsmanship in the field of leather shoe manufacturing is about to unfold.

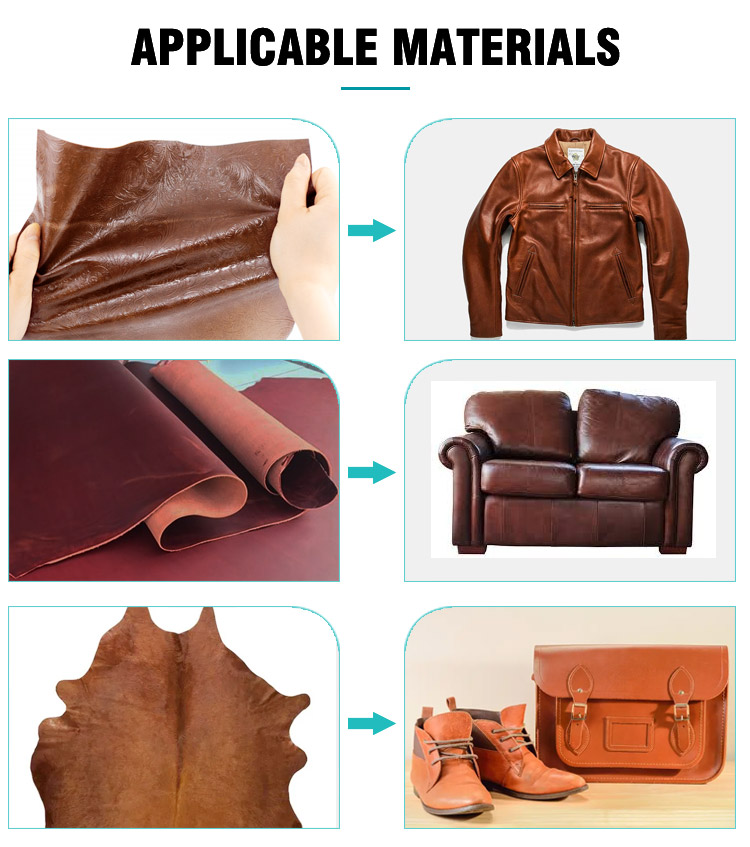

Now, let’s talk about why traditional craftsmanship is still so important in the leather shoe industry. It’s all about skilled artisans bringing a blend of artistry and practicality to their creations. These artisans have an innate understanding of the material leather. They can select the best leather and transform it into shoes that are not only durable and comfortable, but also beautiful.

Challenges and limitations faced by artisans in the traditional leather cutting process

Precision and Consistency: Achieving consistent precision in leather cutting is demanding, especially when dealing with intricate patterns. The variability inherent in hand cutting can cause irregular shape and size issues.

Waste: Traditional cutting methods generate more material waste than modern CNC machines. This inefficiency can lead to increased costs and environmental concerns.

Labor Intensive: The traditional leather cutting process is labor intensive and time consuming. Meticulous detailing and manual cutting can significantly extend production times.

Limited scalability: Traditional methods are not well suited for mass production, making it difficult for small-scale artisans to meet market demand.

In conclusion, the historical context of leather shoemaking takes us on a journey through time, highlighting its enduring legacy. The importance of traditional craftsmanship lies in its ability to imbue shoes with artistry, heritage and a distinct human touch. Still, artisans grapple with challenges related to precision, waste, labor and scalability in traditional leather cutting processes, which can find innovative solutions through the integration of digital precision technologies such as CNC cutting machines.

Digital precision in shoe manufacturing

Digital precision is all about achieving superior accuracy, consistency and efficiency through the use of cutting-edge digital technology. Essentially, this is a shift from traditional, hands-on processes to embracing the power of advanced digital tools and methodologies.

Unlike traditional manual methods, CNC machines operate with astonishing precision and efficiency. They follow precise digital instructions, ensuring that every cut is perfect, every curve is perfect, and every intricate design detail is faithfully reproduced.

Uncover the ability of CNC cutting machine in leather processing

Precision: CNC cutting machines are masters of precision. They can execute the most complex designs with microscopic precision. Whether creating an intricate pattern for a pair of brogues or shaping the components for a stylish high-heeled sandal, CNC ensures that every cut is accurate to the millimeter, taking any guesswork out of manual cutting.

Efficient Material Use: Efficiency is at the heart of modern manufacturing, and CNC technology excels at it. Digital templates are created to maximize the use of hides, thus greatly reducing waste. In a world where sustainability is paramount, this efficiency not only saves costs, but is also an environmentally friendly practice.

Speed and Consistency: Compared to traditional methods, CNC cutting machines are lightning fast. They can produce consistent, high-quality components at a rate that far exceeds manual processes. This level of consistency is especially important when mass producing shoes or complex designs that require consistency.

Complex geometries and intricate designs: the world of leather shoe design has evolved to embrace complexity and innovation. A CNC digital knife cutting machine is the ideal tool for turning these complex design ideas into reality. Whether making intricate cutouts or achieving perfectly beveled edges, CNC technology expands the possibilities of footwear design.

Exact Fit: Ensuring that every shoe fits perfectly is the hallmark of the industry. CNC cutting machines excel in this area, achieving precise and consistent dimensions of all footwear components. This reduces the need for post-cut adjustments, streamlining the manufacturing process and ensuring a better fit for the customer.

In essence, CNC cutting machines embody the pinnacle of digital precision in leather shoe manufacturing. They bridge the gap between the creative design concept and the final product, ensuring that each shoe meets the highest standards of quality, accuracy and efficiency. As we explore further, we’ll discover how the fusion of CNC technology and traditional craftsmanship creates a harmonious partnership, bringing the age-old art of shoemaking into the digital age.

The introduction of CNC (Computer Numerical Control) cutting machines heralds an era of change. With unrivaled precision, these machines can easily replicate complex designs while simplifying production. They are not meant to replace artisans, but to complement their skills, ensuring that every handcrafted detail retains its authenticity. If you want to learn more, please contact us by email [email protected] or whatsapp+86 18560162709!