In addition to cutting graphite plates, the graphite plate cutting machine is also suitable for cutting thousands of materials. It can replace the vibration knives, pneumatic knives, scribing knives, drag knives, punching knives, round knives and other knives. Compared with punching machines and other cutting forms, the gas vibration knife graphite plate cutting machine has a relatively good cutting effect and does not require molds. , and can cut graphite metal gasket cutting.

Graphite plate has good electrical conductivity, high temperature resistance, acid resistance, alkali corrosion resistance and easy processing and other good characteristics, so it is widely used in metallurgy, chemical industry, electrochemistry and other industries.

Advantages of graphite plate cutting machine:

1. No need for mold, data import and cutting, low cost

2. High cutting precision, pulse positioning, cutting error ±0.01mm.

3. Strong practicability, suitable for cutting graphite plate, asbestos, PTFE and other plates, and also suitable for cutting various flexible materials.

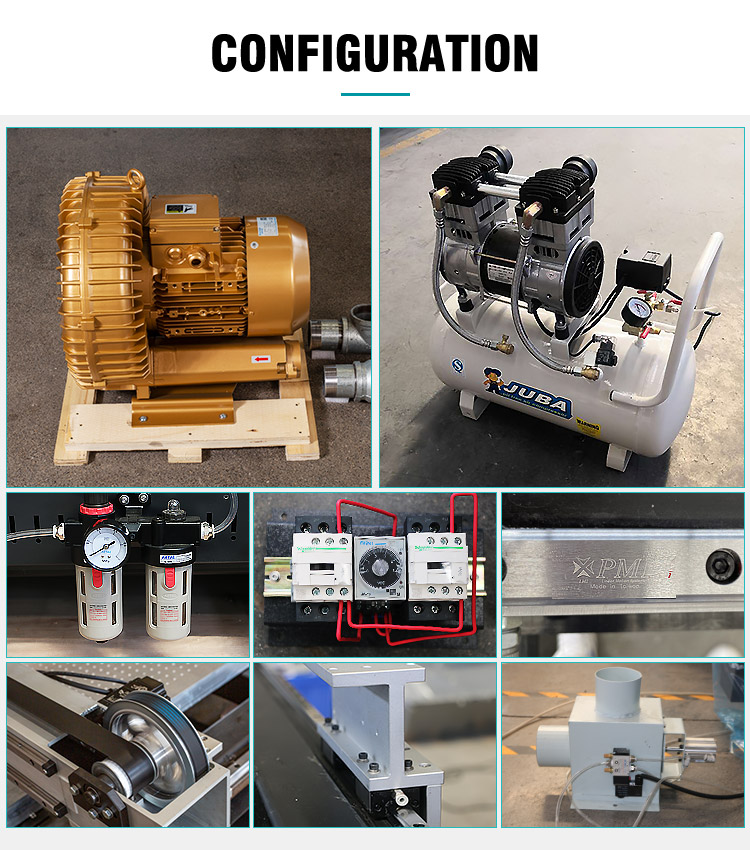

4. High-strength honeycomb aluminum table top, imported felt conveyor belt, and large suction fan are used to ensure that the product has a super adsorption force when processing products.

5. Using Japan’s Panasonic servo motor, it has the characteristics of high speed, high response and high stability.

6. Automatic edge finding and positioning function. Using high-definition CCD camera to achieve automatic positioning of various materials

7. High-precision distance detection sensor realizes automatic positioning and cutting of various materials, eliminating the occurrence of inaccurate manual positioning, thereby improving the accuracy of sleeve cutting

8. The system intelligently optimizes typesetting and cutting, providing better cutting and filling paths and saving materials

Graphite plate cutting machine parameters:

|

Technical parameters / model |

AOL-1625 |

AOL-1825 |

|

Effective working area |

1600x2500mm |

1800x2500mm |

|

Multi-function tool |

Vibrating knife full cut, semi-cutting cut, indentation, drawing mark, cursor positioning, camera positioning edge cutting, high power active round knife |

|

|

safety devices |

Safety devices use infrared sensing, safe and reliable |

|

|

Cutting speed |

200-2000mm/s |

|

|

Cutting thickness |

≤50mm Other thicknesses can be customized according to the material |

|

|

Applicable materials |

Knitting, woven, fur (sheep shearing), PU leather, oxford cloth, canvas, sponge, imitation leather, cotton linen, blended fabric etc. All kinds of clothing, bags, sofa fabrics and carpet fabric etc |

|

|

Material fixing method |

Vacuum partition adsorption |

|

|

Transmission port |

Network port |

|

|

Transmission system |

Yaskawa servo motor, linear linear guide, timing belt, lead screw |

|

|

rated power |

11kw |

|

|

Rated voltage |

380V±10%/220V±10% Optional |

|

|

Control System |

Chinese and English LCD touch screen |

|

|

Operating environment |

Operating environment Temperature 0-40°C Humidity 20%-80%RH |

|

|

Support file format |

AI、PLT、DXF、CDRetc |

|

|

Overall size |

3570x2290x1165mm |

3570x2500x1165mm |

Why choose our CNC cutting equipment?

AOL has been committed to the production and optimization of CNC cutting machines. We have an independent factory, which can fully realize the design, production, sales, delivery and after-sales service processes. The graphite plate cutting machine is fast, easy to operate, perfectly realizes the cutting shape you want, and the whole process is automated without manual intervention. It adopts high-efficiency and high-precision servo motors, which can realize intelligent cutting faster and more accurately. Perfect pre-sale and after-sale service, pre-sale tailor-made plans for you according to the specific situation of your cutting materials, and one-to-one after-sale guidance to ensure that you can master the operation method as soon as possible.

AOL Services:

1) Three-year free warranty (except wearing parts), free inspection and maintenance of main parts.

2) Provide lifetime free technology upgrade service

3) Wearable parts (eg blades, bench covers) are always available at cost when needed.

4) Free operation training in our factory. If there is not enough time, we will send detailed training videos.

5) 24-hour online service, providing free technical support in different languages.

6) On-site technical support is available when needed.

7) AOL accepts unreasonable returns within 7 days after receiving the goods.

If you want to know more about performance issues, please leave a message , we will have a professional staff contact you.