The intelligent fiberglass cutting machine is a modern and innovative equipment widely used in the fiberglass industry. For customers, choosing a suitable intelligent fiberglass cutting machine can not only improve production efficiency and reduce operating costs, but also ensure the high quality and precision of the product.

Traditional manual cutting or semi-automatic cutting methods often have problems such as low efficiency, high labor intensity, and low cutting accuracy. Through digital control, the intelligent cutting machine can accurately control the cutting process and automatically complete the cutting task, greatly shortening the production cycle and improving production efficiency.

For customers, this means reduced labor costs and error rates, and a smoother and more stable production process. Moreover, the intelligent system can automatically adjust the cutting parameters according to different needs, so that the same machine can adapt to the cutting of different types and thicknesses of glass fibers, improving the flexibility of the equipment.

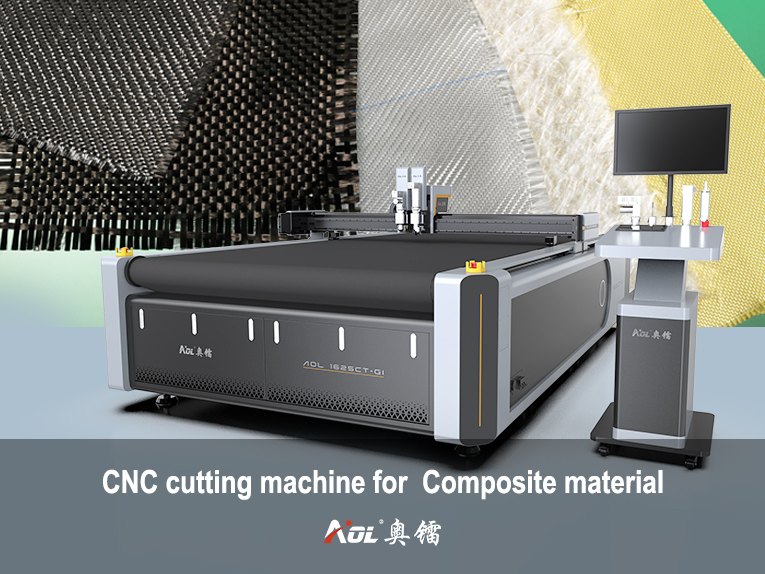

Features of intelligent fiberglass cutting machine:

High cutting accuracy:

The precision mechanical structure and servo drive system enable very fine cutting, capable of providing ±0.1mm accuracy, providing clean, accurate cutting for carbon fiber materials.

Material versatility:

Processes a variety of composite materials such as carbon fiber prepreg, glass fiber mat and aramid, adapting to different weaves and thicknesses.

High production efficiency:

Supports multi-layer cutting with speeds up to 1,800mm/s, improving manufacturers’ efficiency and output.

User-friendly operation:

The intuitive touch screen interface and CAD compatibility simplify setup, while the ability to upload designs via USB reduces preparation time.

Multiple cutting tool options:

The machine is flexibly equipped with a variety of cutting tools such as oscillating knives, rotary blades and drag knives to effectively handle materials of different thicknesses and densities. It can punch, mark and engrave to meet various production needs.

Advanced material handling:

The vacuum suction system ensures material stability during cutting, while the automatic feeding system simplifies continuous roll processing and reduces manual intervention.

You can check out the video below to see the cutting video of the smart fiberglass cutting machine!

Advantages of intelligence:

Automatic adjustment: Depending on the material, the equipment will automatically adjust the cutting parameters, such as cutting speed, pressure, etc., to ensure the best cutting effect.

Adaptive ability: Through artificial intelligence and big data analysis, the equipment can learn and optimize in real time during the production process to adapt to different production needs.

Remote monitoring and maintenance: Some intelligent fiberglass cutting machines support remote monitoring and fault diagnosis functions, which can view the production status in real time and perform remote operations to reduce manual intervention.

The intelligent fiberglass cutting machine combines modern technology with traditional cutting technology, greatly improving the precision, efficiency and automation level of fiberglass material cutting. It can not only adapt to a variety of materials and complex process requirements, but also improve production efficiency while ensuring production quality. Therefore, intelligent fiberglass cutting machines are increasingly widely used in the manufacturing industry, and will continue to develop in a more intelligent, sophisticated and environmentally friendly direction in the future. Click here to get more quotes!