PVC cloth has the advantages of high tensile strength, high toughness, waterproofness, and cold resistance. It is widely used in water sports equipment such as surfboards and kayaks, as well as rescue equipment.

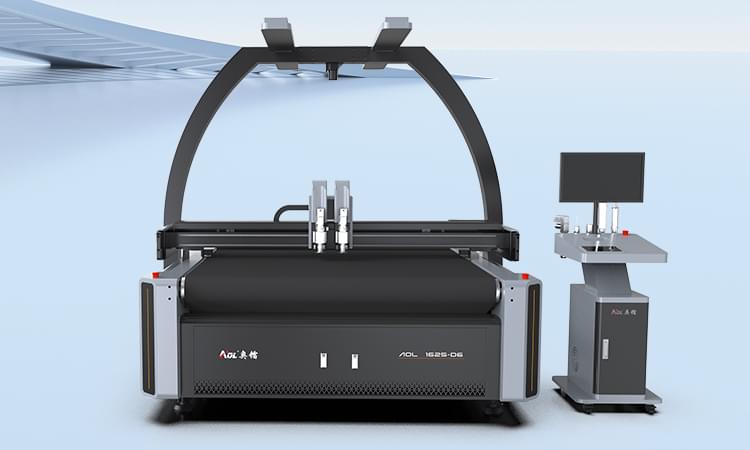

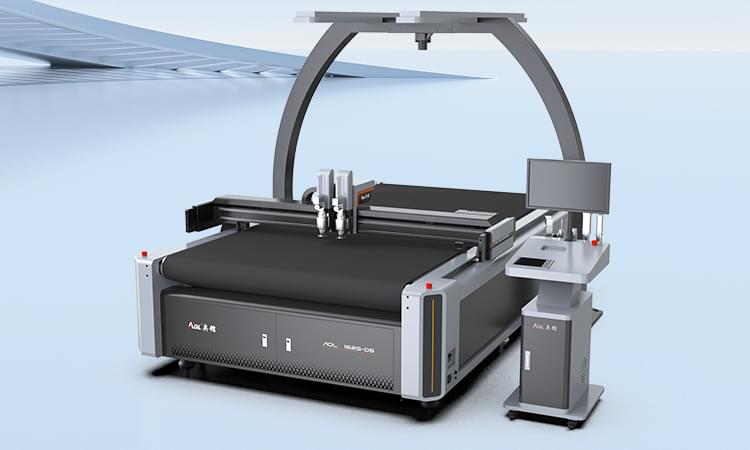

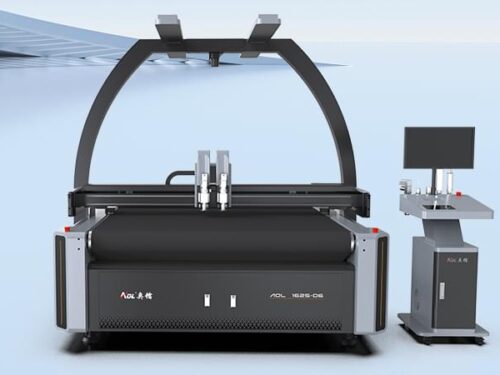

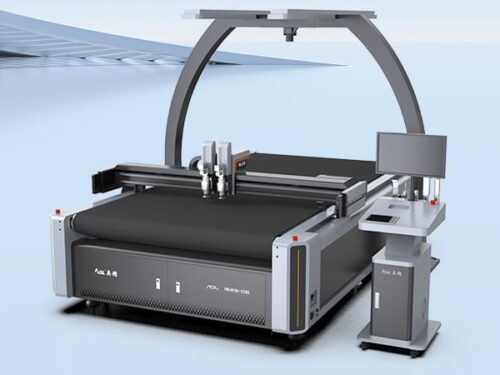

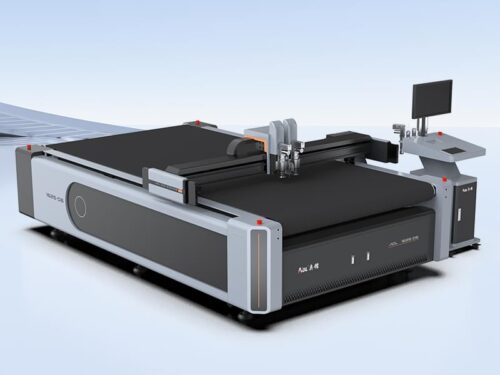

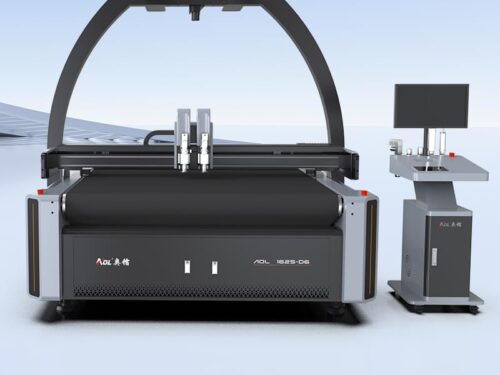

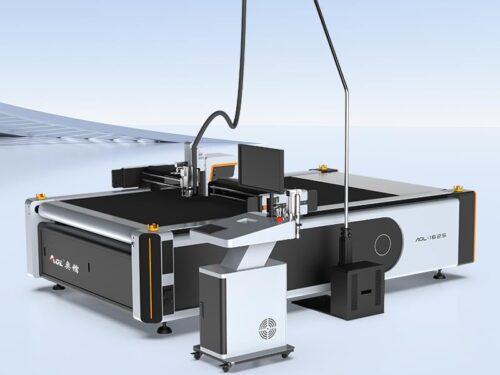

PVC cloth automatic CNC cutting machine is a kind of equipment used for precise cutting of PVC materials (such as PVC plastic cloth, PVC soft film, etc.), which adopts CNC technology for efficient and automatic operation.

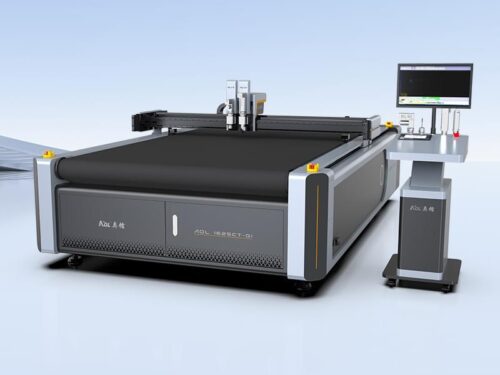

Parameters of PVC cloth automatic CNC cutting machine:

| Technical parameters / model | AOL1625 | AOL1825 | AOL2125 | Accept special model customization | ||

|---|---|---|---|---|---|---|

| Effective working area | 1600x2500mm | 1800x2500mm | 2100X2500 | |||

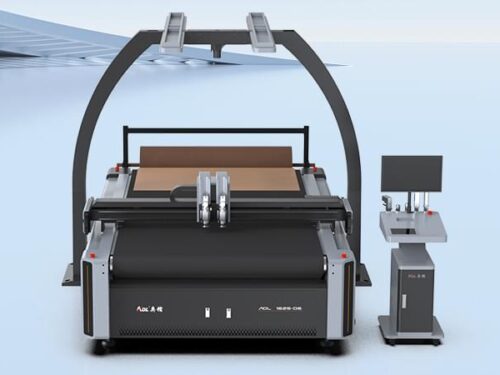

| Multi-head optional | Double head optional efficiency doubled, double gantry optional, double head mutual shift optional, length can be customized | |||||

| Multi-function tool | Vibrating knife full cutting, high power active round knife, punching tool, pneumatic knife, multi-layer knife | |||||

| safety devices | Safety devices use infrared sensing, safe and reliable | |||||

| Cutting speed | 200-2000mm/s | |||||

| Cutting thickness | ≤50mm Other thicknesses can be customized according to the material | |||||

| Applicable materials | foam, vinyl, cardboard, paper, lable, fabric, gasket,cotton, linen, silk, blends, fibers, leather, etc. | |||||

| Material fixing method | Vacuum partition adsorption | |||||

| Transmission port | Network port | |||||

| Transmission system | Imported servo motor, linear linear guide, timing belt, lead screw | |||||

| rated power | 11kw | |||||

| Rated voltage | 380V±10%/220V±10% Optional | |||||

| Control System | Chinese and English LCD touch screen | |||||

| Operating environment | Operating environment Temperature 0-40°C Humidity 20%-80%RH | |||||

| Software | Automatic nesting software, template entry software(Optional) | |||||

| Support file format | AI、PLT、DXF、CDRetc | |||||

| Overall size | 3570x2290x1165mm | 3570x2500x1165mm | 3570x25800x1165mm | |||

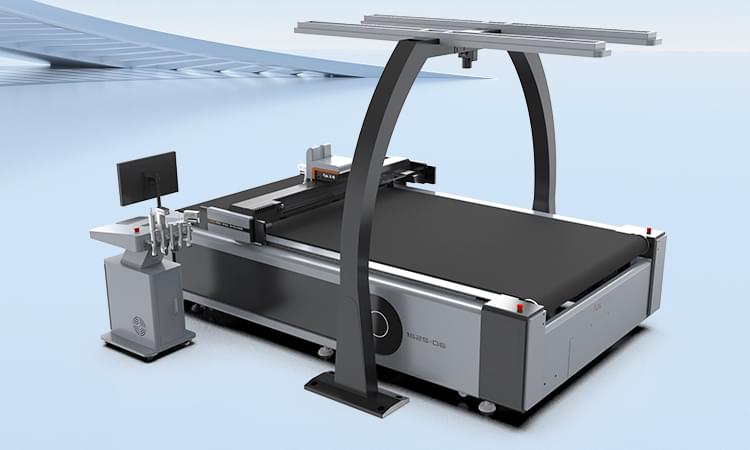

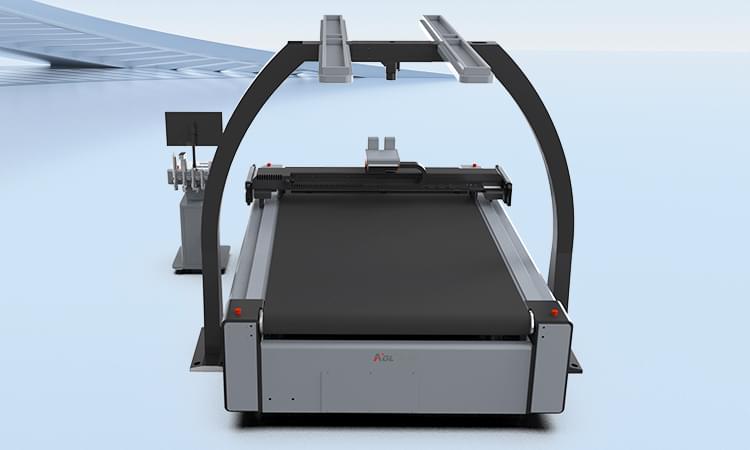

The composition of the PVC cloth automatic CNC cutting machine mainly includes the following points:

CNC system: controls cutting path, cutting speed, cutting accuracy, etc. By inputting the pre-designed cutting drawings (CAD drawings), the CNC system automatically controls the trajectory.

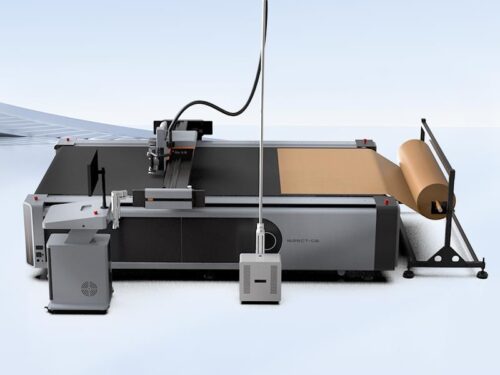

Cutting tools: Common cutting tools include circular knives, vibrating knives or laser cutting. Different tools are suitable for PVC materials of different thicknesses and properties, ensuring high-precision and burr-free cutting edges.

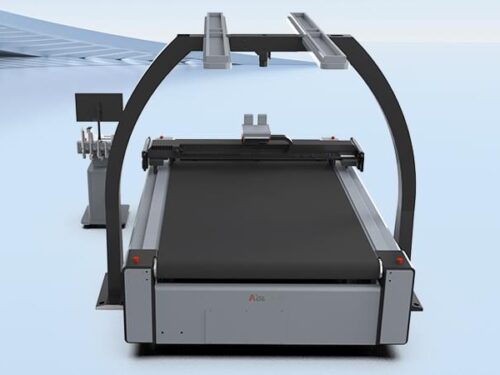

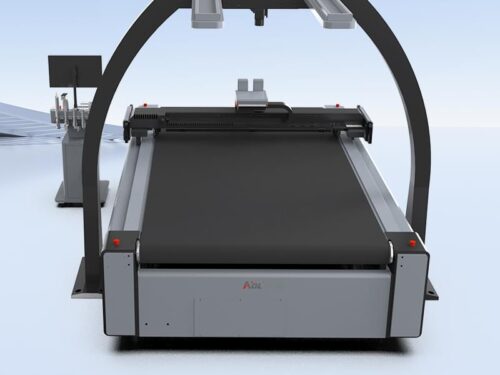

Vacuum adsorption platform: The PVC material is fixed flat on the cutting platform during cutting to prevent the material from moving and ensure accurate cutting.

Automatic feeding system: It can automatically transport PVC fabrics to the cutting area, support continuous and batch production, and improve work efficiency.

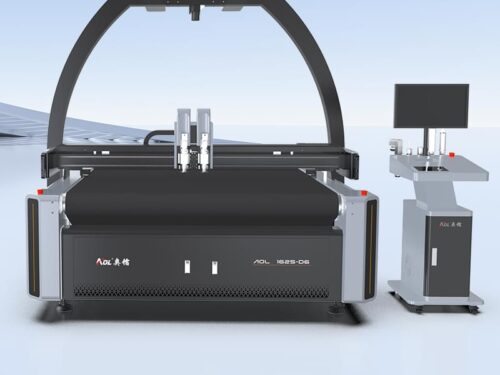

Advantages of PVC cloth automatic CNC cutting machine:

High precision: The use of advanced servo motors, guide rail systems and optical sensors ensures the accuracy of the cutting process, which can achieve the accuracy requirement of ±0.1mm.

Automated control: No manual intervention is required, and automated mass production can be achieved through programming, reducing the error of manual operation.

Diversified cutting: Supports a variety of cutting methods to adapt to PVC fabrics of different thicknesses, shapes and specifications, such as special-shaped cutting, curve cutting, etc.

Supports a variety of materials: In addition to PVC fabrics, it can also cut other flexible materials such as leather, canvas, rubber, etc., with a wide range of applications.

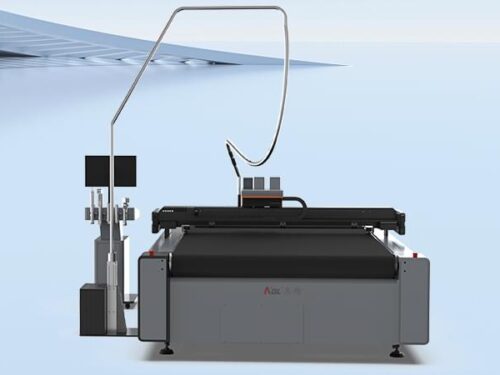

Automatic feeding: The PVC cutting machine uses imported felt material, high permeability cutting friction, automatic feeding will also have clamps to prevent the material from slipping, and the feeding is more accurate. And it can be equipped with automatic correction equipment to assist in feeding, ensuring that the material will not tilt during the feeding process.

Maintenance cost: It only needs to clean the dust on the guide rail regularly and apply lubricating oil, which greatly simplifies the maintenance process and reduces maintenance costs.

The future development trends of PVC cloth automatic CNC cutting machine are as follows:

Intelligent control: Combined with artificial intelligence technology, it can achieve more intelligent cutting path optimization and automatic adjustment to improve production efficiency.

Green and environmental protection: Future equipment will pay more attention to energy conservation and environmental protection, reducing energy consumption and waste emissions during the cutting process.

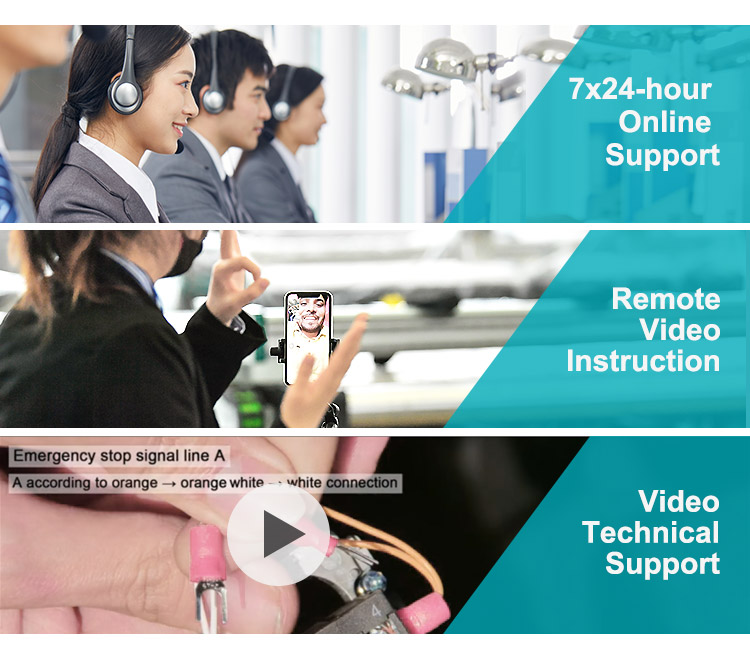

Remote operation and monitoring: Through Internet technology, factories can remotely monitor the working status of equipment and adjust the production process in real time.

Why choose PVC cloth automatic CNC cutting machine?

The vibration knife cutting machine is an automated cutting equipment. First, the working surface is a conveyor belt, which can easily pull the material to the cutting surface of the machine. The material is very flat and rarely has wrinkles and other problems. Then the CNC system drives the vibration knife to quickly cut the cloth. The cutting size is very accurate, and the cutting edge is also very smooth and flat, without sawtooth, which improves the strength of the cloth.

AOL CNC cutting machine is suitable for product customization or sample cutting. It can automatically and accurately perform cutting and other processing. CNC cutting machine supports different types of cutting, (such as through cutting, kiss cutting. V-groove, compliance, milling, etc.

Want to know more machine performance and other information, please leave a message for professional reply.

AOL intelligent blade cutting machine has high precision and high efficiency. Our professional after-sales service can provide automatic cutting solutions for various industries.

For more information, please consult:

Email: [email protected]

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://aollaser.net/

Reviews

There are no reviews yet.