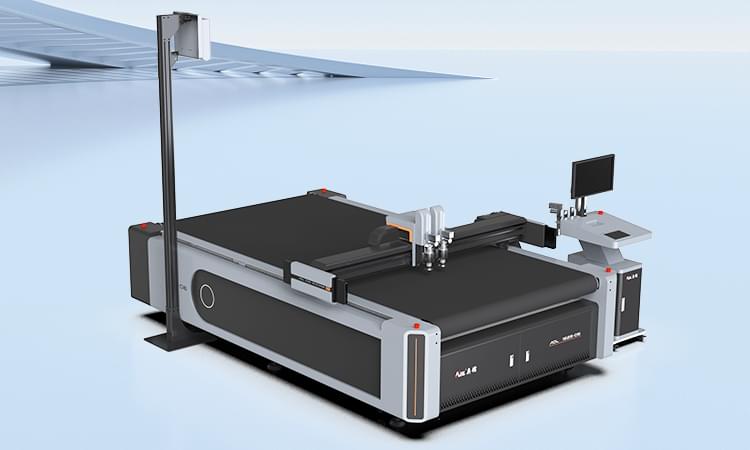

In modern manufacturing, digital cutting machines have become a key technology that has greatly improved the precision and efficiency of the production process. These machines use advanced computer control systems to achieve complex designs and cuts with unparalleled precision. Among them, CNC knife cutting machines are particularly known for their ability to process a variety of materials such as cardboard, leather and wood with extremely high precision.

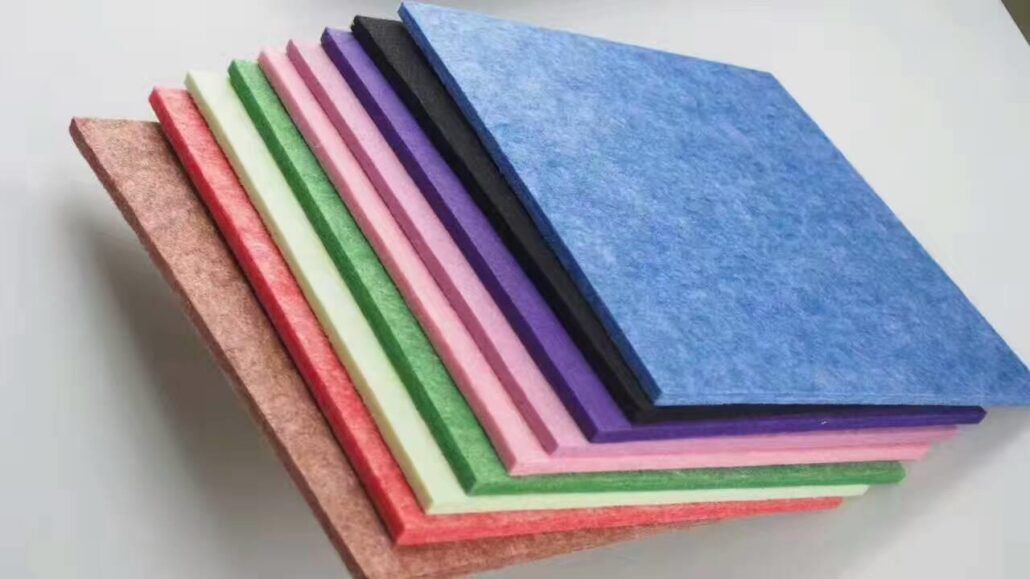

PET felt acoustic panels are becoming increasingly popular as an innovative solution for sound absorption in interior design. Made from recycled polyester fibers, these panels are an environmentally friendly choice that combines functionality with visual appeal. They can be used in a variety of applications, including wall coverings and ceiling treatments, making them a versatile choice for improving the acoustic quality of different spaces.

This article explores the connection between AOL digital cutting machines and PET felt acoustic panels. Specifically, this article explores how CNC knife cutting technology has transformed the production of these panels. In addition, we will discuss the advantages and uses of this combination that make it an outstanding choice in contemporary interior design solutions.

Working principle of digital cutting machine:

CNC Technology: These machines use CNC technology, where computer-aided design (CAD) software controls the cutting process, ensuring that every cut is made exactly to digital specifications.

Mechanism: The main mechanism consists of a movable knife or blade that follows a programmed path. This allows complex designs and patterns to be created without any human intervention.

Features of PET felt sound-absorbing board digital cutting machine:

High precision cutting

Digital cutting machines are usually equipped with advanced control systems and high-precision cutter heads, which can achieve millimeter-level cutting accuracy and ensure smooth cutting lines without burrs.

Suitable for various patterns

Through CAD design drawings, the digital cutting machine can easily complete the processing of complex geometric patterns, text and artistic shapes to meet the diverse design needs of customers.

Efficient automation

The equipment has a high degree of automation, supports continuous work, and significantly improves production efficiency. Some models also support batch processing functions, significantly reducing manual intervention.

No thermal deformation

The digital cutting machine uses a cold cutting process without heating treatment, which avoids the problem of deformation or performance degradation of PET felt sound-absorbing panels due to high temperatures.

Environmental protection and energy saving

Less dust and noise are generated during the cutting process, which conforms to the modern environmentally friendly processing concept and reduces the cleaning and maintenance costs of the production workshop.

Features of PET felt sound-absorbing board:

Sound Absorption: Superior sound-blocking capabilities, making it ideal for enhancing acoustics in busy or noisy environments.

Durability: Resists wear and tear, ensuring long life even in high-traffic areas.

Aesthetic Flexibility: Available in a variety of colors and textures, allowing for creative design adjustments.

Application of PET Felt Sound-Absorbing Panel Digital Cutting Machine:

Digital cutting machines, especially CNC knife cutting machines, play a vital role in the effective installation of PET felt acoustic panels in various environments:

1. Wall Coverings

The precision and versatility of CNC tool cutting allows PET felt panels to be seamlessly customized to fit any wall size or shape. This ensures a perfect fit, reducing waste and installation time.

2. Ceiling Coverings

When applied to ceilings, PET felt panels require meticulous attention to detail. Digital cutters provide the necessary precision to create intricate designs and ensure uniformity across large surfaces.

3. Room Dividers

Since room dividers need to be both aesthetically pleasing and functional, digital cutters can create intricate patterns and designs that enhance visual interest while maintaining sound-absorbing qualities.

Using a digital cutting machine not only increases design possibilities, it also significantly simplifies the preparation process by delivering consistent and high-quality cuts tailored to specific project requirements. The technology supports a variety of applications, making it a valuable tool for modern interior design projects involving PET felt acoustic panels.

When buying a digital cutting machine (especially a CNC knife cutting machine), you should consider the following key factors to make your decision:

1. Size

Consider the table size required for your project. For example, the AOL CNC oscillating knife cutting machine comes with a 1600MM*2500MM table, which is perfect for processing large PET felt acoustic panels.

2. Software Compatibility

Make sure the machine is compatible with popular design software. This ensures seamless integration into existing workflows and increases productivity.

3. Budget

Analyze your budget constraints while keeping in mind the long-term benefits of investing in quality machinery. Balance cost with features that provide precision and efficiency.

For those seeking a reputable supplier, AOL CNC is a noteworthy choice that offers high-quality machines. Known for its comprehensive CNC router and cutting solutions.

As a representative of modern manufacturing technology, digital cutting machines have greatly promoted the development of PET felt sound-absorbing board processing. With its advantages of high precision, high efficiency, and strong flexibility, digital cutting machines not only improve the processing quality of PET felt sound-absorbing boards, but also meet personalized and diversified market needs. Whether in interior decoration, acoustic design or artistic modeling, digital cutting machines provide strong technical support for the application of PET felt sound-absorbing boards and promote the rapid development of the acoustic industry.

With the continuous advancement of technology, digital cutting machines will be more widely used in the future, further promoting the process of environmental protection, energy saving and intelligent production.

AOL intelligent blade cutting machine has high precision and high efficiency. Our professional after-sales service can provide automatic cutting solutions for various industries.

For more information, please consult:

Email: [email protected]

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://aollaser.net/