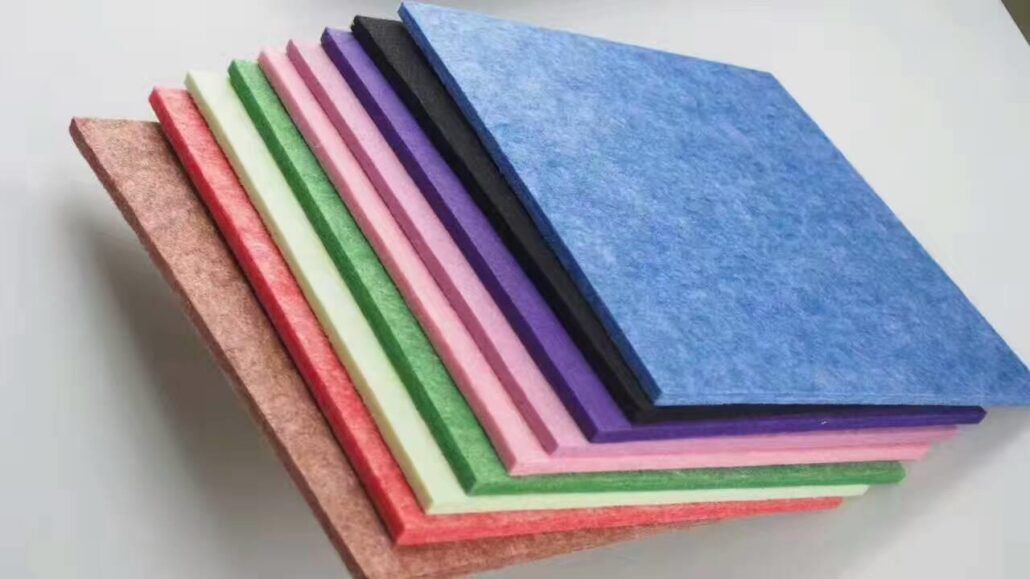

Polyester fiber sound-absorbing board uses environmentally friendly high-density 100% polyester fiber as raw material. PET felt has the characteristics of high density, environmental protection, fire resistance, wide sound absorption bandwidth, strong decorativeness, simple construction, easy cutting, no dust pollution, etc., which can well meet the diverse acoustic and decorative needs of customers. Because the product is close to nature, harmless to the human body, rich in colors and patterns, it can create a quiet and comfortable working and living space. It is simple to construct and has strong decorativeness, and can be used directly as a decorative material.

PET felt is suitable for places with strict acoustic requirements such as opera houses, theaters, recording studios, audition rooms, TV stations, conference rooms, studios, gymnasiums, hotels, KTVs, etc.

PET felt cutting machine is a professional sound-absorbing board processing equipment. Compared with traditional manual cutting, the sound-absorbing board cutting machine uses CNC blade cutting, which has the ability to perform three processes of slotting, punching and cutting, and due to its high-frequency vibration characteristics, the cutting speed is faster and the precision is higher.

The CNC vibration knife of PET felt sound-absorbing board is a technology that uses high-frequency vibration technology to achieve precise cutting of materials. This is a contact processing method based on tool processing technology, combined with servo operation control and high-amplitude vibration knife motor, which drives the tool to cut the material, so that the vibration tool and the material move relative to each other along a certain trajectory, thereby forming a cutting effect of a certain shape. The vibration knife cutting machine has high precision, fast speed, continuous operation and high flexibility.

The application field of PET panel cutting machine is very wide, such as cloth, pearl cotton, fiberglass, corrugated paper, carton, soft PVC crystal pad, leather, sponge, advertising material, composite material, etc. The use of this equipment has greatly improved production efficiency and product quality, and provided strong support for the production and manufacturing of enterprises.

The bevel knife is a blade mounted on an angled bracket, and the blade has a sharp edge for separating the material to be cut. The machine drives the blade to cut along the same trajectory on both sides to form a V-shaped groove. The angle of the bracket can be adjusted to form V-shaped grooves of different angles, such as 45 degrees, 60 degrees, 90 degrees, etc.

The depth of the bevel knife can be controlled and adjusted, and the desired cutting depth can be obtained on the sound insulation board by setting the corresponding parameters as needed.

Punching knives are mainly used to make small round holes. When making small round holes, punching knives are faster than vibrating knives, and the circles they make are more regular and standard. The punching knife is a rotating spindle. During the cutting process, the punching knife itself rotates at high speed, and then the motor drives the punching knife to move up and down to complete the punching action.

Advantages of Sound-absorbing Panel Cutting Machine

The sound-absorbing felt cutting machine has many advantages when cutting sound-absorbing panels. First, the vibration knife cutting machine adopts a blade cutting method, which can realize slotting, punching, and cutting synchronously, greatly improving work efficiency. Secondly, the vibration knife cutting machine adopts high-frequency vibration technology, which can ensure that the cutting edge is very neat and without any burrs, thus ensuring the quality of the product.

In addition, the cutting speed of the sound-absorbing panel cutting machine is very fast, which is due to the use of high-speed vibration tools for cutting. At the same time, the vibration knife cutting machine is also equipped with super typesetting software and automatic error compensation system. These two functions can help users save materials and improve material use efficiency.

Especially for the cutting of sound-absorbing panels, the vibration knife cutting machine shows its advantages of high efficiency and precision. Whether it is a hard sound-absorbing panel or a soft fiberboard, the PET felt cutting machine can quickly complete the cutting task. Therefore, for manufacturers who need to produce a large number of sound-absorbing panels, using a vibration knife cutting machine is undoubtedly an ideal choice.

Workflow of PET Felt Acoustic Panel CNC Vibrating Knife:

The process of cutting acoustic panels using the PET panel cutting machine is very simple and efficient. Here are the basic steps:

1. Place the acoustic panel on the machine table and keep the material aligned as much as possible. The machine vacuum system will fix the panel to prevent it from moving during the cutting process.

2. Adjust the position of the blade to the desired depth and angle. This can be controlled and adjusted in the machine controller.

3. Turn on the acoustic panel cutting machine and set the speed according to the thickness of the acoustic panel. You can gradually increase the cutting speed to maximize efficiency while satisfying the cutting effect.

4. Download the CAD drawing from the computer to the machine. The blade will vibrate at high speed, thus cutting the material quickly.

5. After the cutting is completed, turn off the machine and remove the acoustic panel from the surface.

6. Clean up any debris or dust generated during the cutting process.

AOL intelligent blade cutting machine has high precision and high efficiency. Our professional after-sales service can provide automatic cutting solutions for various industries.

For more information, please consult:

Email: [email protected]

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://aollaser.net/