At some point in your life, you must have cut a piece of cloth with scissors. You have to lay the fabric flat on a table to cut it with the help of scissors, or fold the fabric to do the same.

Another common method followed by most people and industries is that the assistant holds one end of the cloth and the person holding the scissors holds the other end and uses the scissors to cut the cloth in two over the folded edge. This process is not only time-consuming, but also labor-intensive.

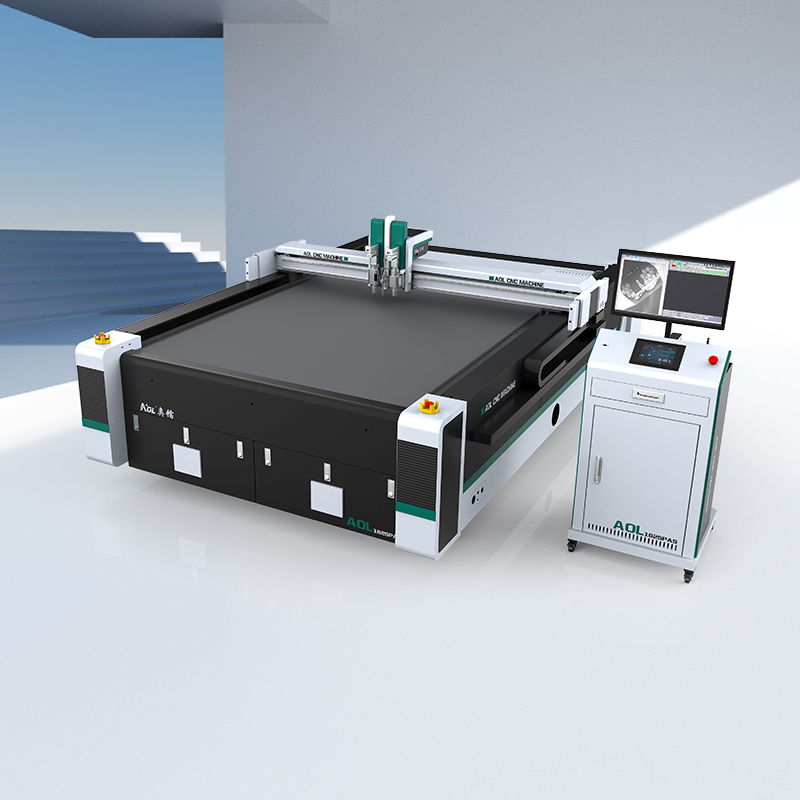

However, with the development of digital cutting machines, the problem became the solution. These high-tech machines are a blessing in disguise for industrial and manufacturing companies.

With the advent of CNC cutting machine technology in the textile industry, new levels of innovation have emerged, thereby overcoming the weaknesses of traditional cutting methods. For more in-depth knowledge, read this blog.

How are CNC cutting machines used in the fabric and textile industry?

CNC cutting machines are very popular in the market. This cutting solution provides the most precise cuts. This advanced technology has the advantage of being highly accurate and fast, but it does cost more than traditional cutting solutions. A CNC machine is an electromechanical device that uses a tool with computer programming input. CNC cutting machines are suitable for both small production lines as well as small and large production lines for cutting textiles/fabrics.

The cutting of clothing patterns, the design of ties, the engraving of leather, and the fading of denim are all done by CNC vibrating knife cutting machines. Cutting machines are widely used in the apparel industry due to cost reduction, flexibility and anti-counterfeiting. According to recent surveys, it has been observed that the application of blade cutters in denim distressing is increasing, thereby replacing traditional techniques. This technology has finally made the cutting machine one of the best machines for fabric and textiles.

CNC cutting machines can cut a variety of non-metallic materials. The uniqueness of the garment manufacturing industry requires CNC cutting equipment. Traditional cutting machines will move materials when cutting, resulting in inaccurate cutting. Traditional methods often require the assistance of an operator who can check while cutting.

You wear clothes every day to protect against harsh weather. You will wear different clothes according to the season. Sometimes, you wear your favorite clothing, accessories, shoes, etc., but have you ever thought about how they were made?

Digital industries are transforming to improve business models, which in turn improve markets. Advanced digital cutting machines provide end users with unrivaled cutting capabilities on flexible substrates. With its precision and smooth motion, the digital cutting machine is an easy-to-use cutting tool for small and large businesses alike. This advanced machinery is used in the advertising industry, such as outdoor and indoor flexible advertising boards, fabrics, textiles, carpets, MDF cutting, automotive interior cutting and processing other non-metallic materials, etc. CNC blade cutting machines play an important role in the textile industry and their numbers are always growing. Cutting machines use a cold cutting process to cut patterns and designs on textile materials.

Textile CNC cutting machines are more precise and use less energy when cutting different materials. Compared with traditional cutting methods, its precision and efficiency are commendable. Its cutting technology also allows us to cut complex shapes without the need for tools at a speed similar to or faster than other cutting methods.

This high-tech machine is used to cut different materials such as silk, nylon, leather, neoprene, polyester and cotton. The cutting precision is high, and no accidental marks will be left on the fabric when cutting, so it is beneficial to delicate fabrics such as silk and lace.

Today, textile CNC cutting machines have been widely accepted by manufacturing companies. This highly advanced technique cuts material with less labor and in less time than traditional methods. From cutting faux leather materials to silk, nylon, polyester, faux fur, wool, leather and faux leather, lycra, various mesh fabrics, ripstop and other fibers, cotton, neoprene, natural and synthetic felt, suede leather, rubber and rubber textiles, this persuasive technique allows you to efficiently cut beautiful and sophisticated garments.

In recent years, garment textile CNC cutting machines have been used more and more in the garment industry. From cutting garment patterns to designing designer tie patterns, 3D body scanning, denim fading and leather engraving, this machine guarantees quality. Additionally, the use of cutting machines is increasing due to the precision with which parts are cut. Apart from clothing, fashion accessories such as accessories are also cut using blade cutters to produce new and unusual designs. Make the product look high-end and exquisite.

If you are looking for CNC cutting machines for your textile industry, then you can opt for CNC blade cutting digital solutions due to its CNC technology. Want to know more, looking forward to your contact us!