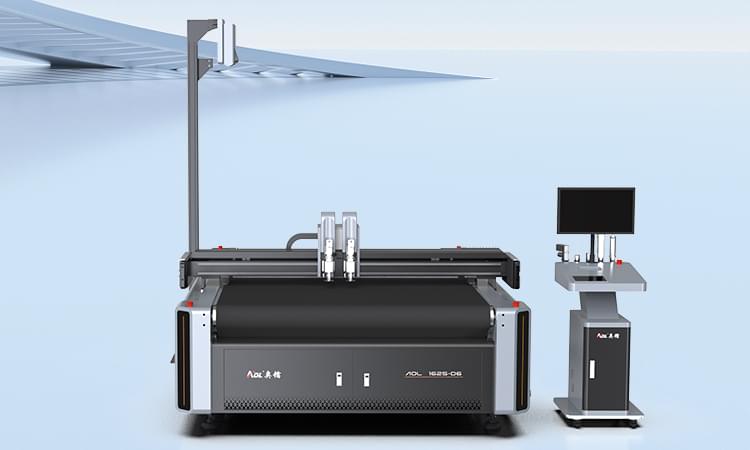

The CNC cutting machine for upholstered sofas is a device specially used for efficient and accurate cutting of upholstered materials (such as sponges, foams, cotton, etc.) in sofa manufacturing. It uses CNC technology (CNC) and can be automatically operated through programming control, thereby greatly improving production efficiency and cutting accuracy.

The vibration knife cutting machine can complete cutting, punching and marking in one machine to meet the different processing requirements in sofa customization.

The vibration knife cutting machine emphasizes reducing the negative impact of the process on the environment by adopting more advanced technology, reducing noise and dust pollution and energy consumption, and meeting the needs of sustainable development.

It can easily adapt to the personalized needs and assistance of customers, help enterprises stand out without much competition, and promote the vertical development of the sofa customization industry.

Advantages of CNC cutting machine for upholstered sofas:

Meet diverse cutting requirements

Special-shaped cutting

In sofa customization, for parts with complex shapes, such as curved sofa armrests and personalized backrest shapes, the CNC vibration knife cutting machine can accurately cut according to the design requirements, with an accuracy of up to millimeter level, ensuring that each part of the sofa meets the customized size and shape, making the sofa look more refined.

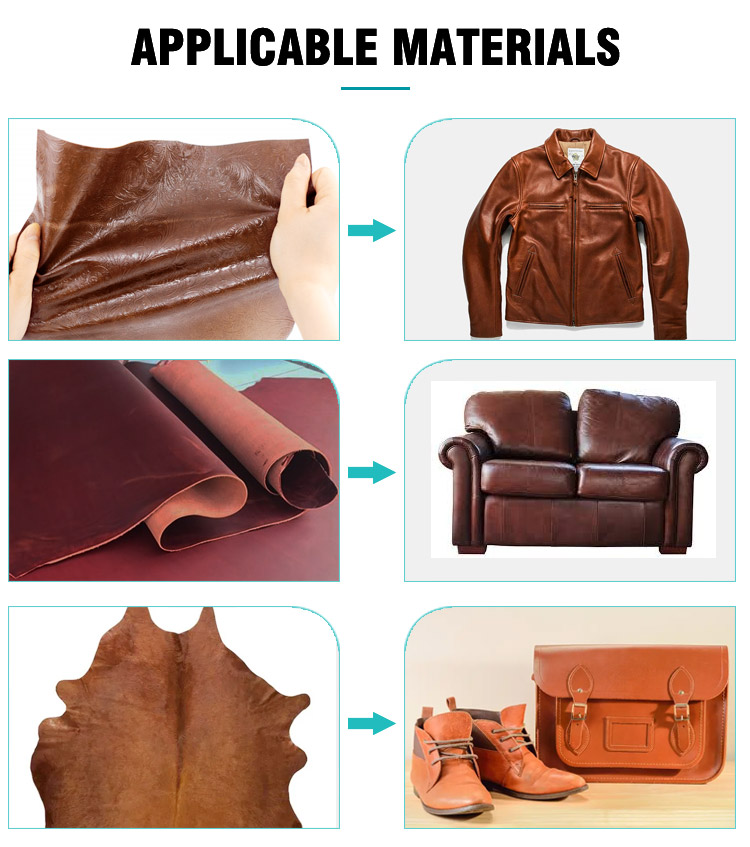

Material diversity

The materials of the sofa include various fabrics, leathers, sponges, etc. The CNC vibration knife cutting machine can adapt well to these different materials. Soft fabrics can be cut gently to prevent fuzzing on the edges; for thicker leather and sponges, appropriate cutting force can also be used to ensure the flatness of the cutting surface to meet the material requirements of different parts of the sofa.

Improve material utilization

The CNC cutting machine for upholstered sofas has high cutting accuracy and can cut sofa parts according to precise dimensions. When processing sofa fabrics, leather and other materials, the cutting patterns can be arranged closely to reduce material waste. For example, regular-shaped cushions and backrest materials can maximize the use of every inch of the material and minimize the generation of waste.

High efficiency and short delivery cycle

When customizing sofas, customers usually want to receive products in a shorter time. The digital knife cutting machine is easy to operate, highly automated, and has a fast cutting speed. It can quickly complete the cutting of various parts of the sofa, greatly shortening the production cycle of customized sofas, allowing the sofa industry to deliver products more promptly when facing customized orders.

With the advancement of technology, CNC cutting machines for upholstered sofas are also developing continuously. For example, the introduction of cutting technology has made cutting more accurate and faster; in addition, the application of intelligence and Internet of Things technology will also make the machine more intelligent, capable of automatic monitoring and fault diagnosis, and improve the overall efficiency and automation level of the production line.

In general, the CNC cutting machine for upholstered sofas is an indispensable and efficient equipment in modern sofa production. It can greatly improve production efficiency, reduce costs, and improve product quality. It is an important step in the modernization and intelligence of sofa manufacturing companies.

AOL intelligent blade cutting machine has high precision and high efficiency. Our professional after-sales service can provide automatic cutting solutions for various industries.

For more information, please consult:

Email: [email protected]

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://aollaser.net/