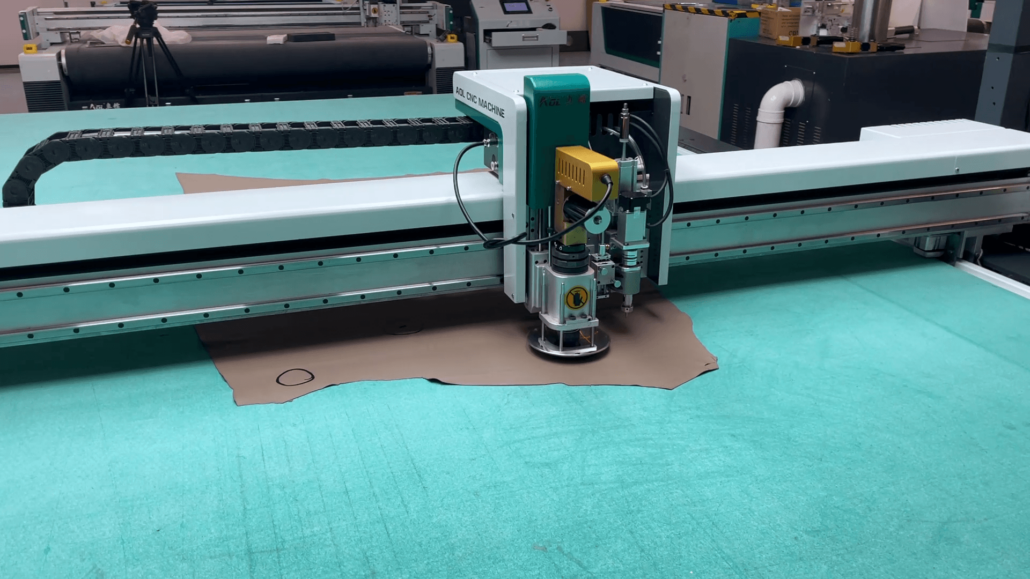

The global leather upholstery industry is facing major challenges. The growing tastes of end customers lead to an increased degree of product customization. At the same time, the rising prices of raw materials worldwide and the cost of a highly qualified workforce are also very important aspects. They increase the pressure to increase production to cover new opportunities in emerging markets. AOL equipment manufacturers understand these needs and provide the best performing technical solutions for the core of this business: the leather cutting room.

Saving hides is often seen as a problem related only to nesting efficiency. While the AOL leather cutting machine offers high nesting performance, it also exploits all opportunities to optimize other areas of the leather cutting room that are often neglected.

Automatic nesting:

Multi-leather nesting: The offline workflow allows all hides to be nested simultaneously, a key factor in achieving high efficiency and reducing reusable waste.

Multi-machine technology: The huge computational requirements of multi-leather nesting can be met by executing the same nesting job in parallel on multiple PC.

Adaptive strategy: The nesting algorithm automatically adapts to the characteristics of all hides and models, achieving high-quality, stable results regardless of the diversity of production.

Reduced re-cutting:

Process analysis: Full traceability of all process steps, and powerful analysis tools to quickly identify any factors that lead to increased re-cutting in the process.

Nesting functionality: Automatically placing parts as far away from the edge of the leather as possible without losing efficiency has a significant impact on reducing the number of re-cuts.

Better utilization of leather surfaces by improving scanning accuracy:

Machine accuracy: High accuracy in leather scanning is a key factor for efficient utilization of leather surfaces without compromising quality.

Activity control of scanner operators: The advanced analytics module allows statistical analysis of each operator’s performance in terms of leather scanning accuracy, which helps to improve the utilization of leather surfaces.

Your employees are very important to the production process. The effective use of their skills and traceability are essential. Given the high labor costs, especially in Europe and the United States, increasing the efficiency of operators without overqualification is a major economic advantage.

Machine Automation:

Scanning: The AOL leather scanner is extremely easy to operate, allowing the operator to focus only on identifying quality areas, thus achieving high processing speeds without compromising quality.

Cutting: Our solutions include automation systems for different types of cutting machine configurations, which can optimize each step of the process by using augmented reality to place the leather and collect the cut parts.

Fully traceable production processes:

Process analysis: Complete data logging of all production steps as well as advanced analysis modules bring significant benefits to the optimization of the entire process.

Machines are the heart of a production line, so it is vital to make full use of them. AOL is designed to maximize the capacity of machines, thereby significantly increasing production.

Each step of the scanning and cutting process is highly automated to maximize the machine’s capabilities and reduce operator effort.

Leather typesetting software is an important technical tool in the modern leather processing industry, which can greatly improve material utilization, reduce production costs, and improve product quality. With the development of technologies such as artificial intelligence and machine learning, future leather typesetting software will be more intelligent and deeply integrated with automated production lines to achieve true intelligent manufacturing.

If you want to get a quote or learn more about typesetting, please click here to leave a message and we will answer you as soon as we receive the message!