With the changes of the times, the update of technology, and the gradual trend of high-end and refined market demand, advertising companies need to change their operating modes and need high-tech equipment to help upgrade and transform. So how do advertising companies choose digital cutting equipment to make advertising products more precise? So how to choose a special-shaped cutting machine, many people pay more attention to the price of the special-shaped cutting machine. In fact, this is not the case. When choosing a special-shaped cutting machine, in addition to paying attention to the price, there are many aspects that everyone cares about Question, please read the following patiently to understand!

1. Price of special-shaped cutting machine: Regarding the price, it is a dominant factor in purchasing special-shaped cutting machine, and it is also a factor that everyone attaches great importance to;

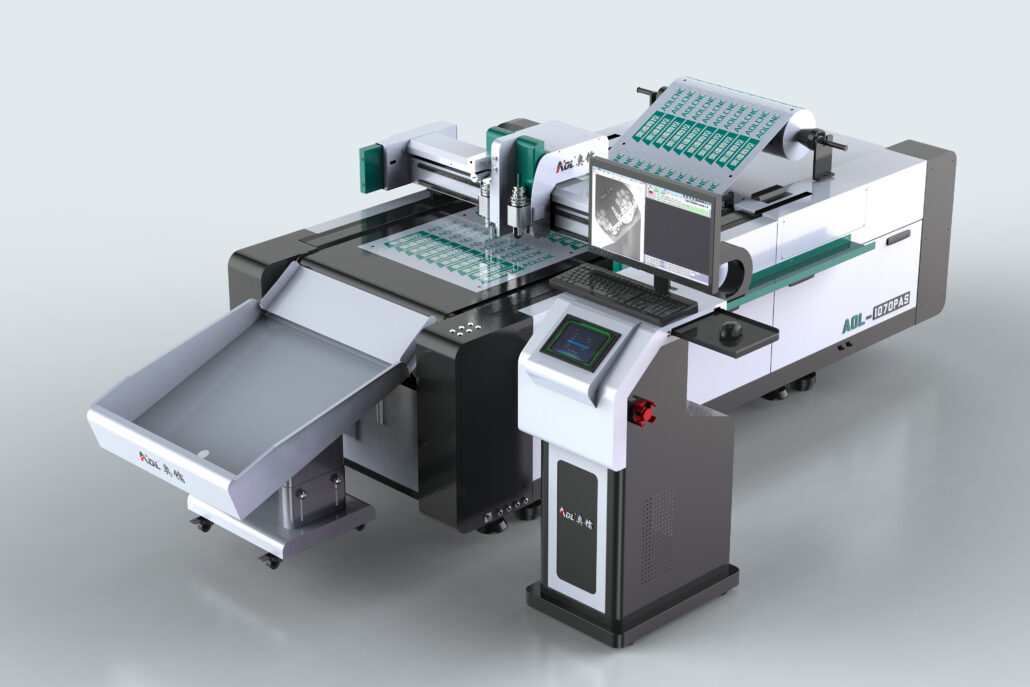

2. Special-shaped cutting airport site: The site mentioned here refers to the area of the special-shaped cutting machine. The price of the site in the market is getting more and more expensive. In the case of meeting the functional requirements, of course, it is necessary to choose a small size. Special-shaped cutting machine that does not occupy a lot of space;

3. Energy consumption of special-shaped cutting machine: In the case of meeting the functional requirements, try to choose a special-shaped cutting machine with low energy consumption. Maybe many people think that the higher power means that the equipment is updated and the accessories used are better. In fact, It is not the higher the better, but the appropriateness, reducing energy consumption and saving electricity.

4. The performance of the special-shaped cutting machine: to buy a piece of equipment of more than ten thousand yuan, of course, it is necessary to choose the one with stable performance and low failure rate, so as to ensure the company’s output and timely delivery of orders;

5. Efficiency of special-shaped cutting machine: The purpose of purchasing special-shaped cutting machine is to improve production efficiency, improve product accuracy, and enhance brand competitiveness… Therefore, special consideration should be given to whether the working efficiency of special-shaped cutting machine can meet its own needs. Require.

The advantages of AOL special-shaped cutting machine:

1. One-click import of self-developed software, ordinary workers can work skillfully within 2 hours

2. Adopt Taiwan linear guide rail drive system, the accuracy is ±0.1mm

3. AOL quick tool change system provides a variety of tool options for various materials

4. Super nesting software, the material utilization rate is increased by more than 10%

5. Automatic pulling and unloading, saving time, labor and more environmental protection, saving electricity and frequency conversion vacuum adsorption, saving more than 30% of electricity.

6. The infrared induction safety device ensures the safety of the operator during the high-speed movement of the machine, and at the same time avoids the loss of cutting materials.

7. Using Japanese Panasonic servo system, the production efficiency is increased by more than 5 times

8. Professional R&D team can provide assembly line supporting solutions

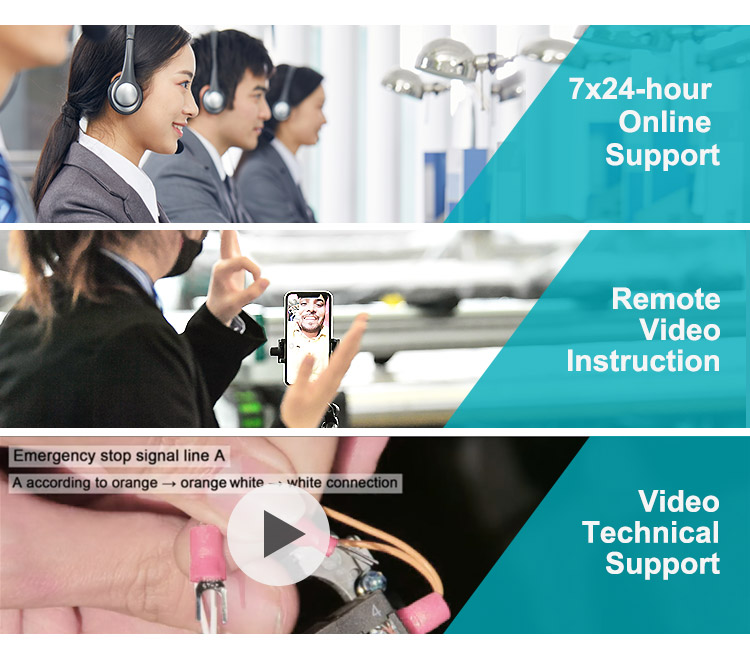

AOL Services

1) Three-year free warranty (except wearing parts), free inspection and maintenance of main parts.

2) Provide lifetime free technology upgrade service

3) Wearable parts (eg blades, bench covers) are always available at cost when needed.

4) Free operation training in our factory. If there is not enough time, we will send detailed training videos.

5) 24-hour online service, providing free technical support in different languages.

6) On-site technical support is available when needed.

7) AOL accepts unreasonable returns within 7 days after receiving the goods.

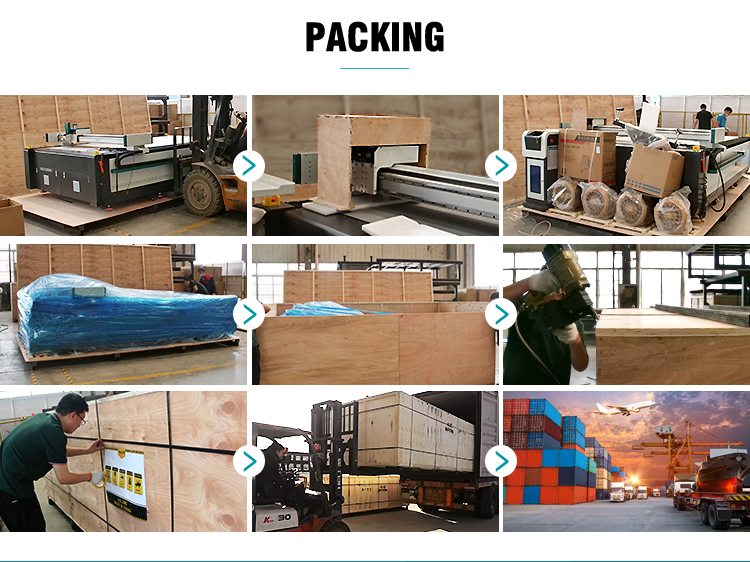

Packaging of the cutting machine

1. Outer packing: Standard sea export plywood box.

2. Inner packaging: stretchable film and plastic film to prevent moisture.

If you have special requirements, we can negotiate amicably

If you want to know more about performance issues, please leave a message , we will have a professional staff contact you.