Challenges faced by traditional die cutting

Time consuming

The traditional method takes at least three days from receipt of drawings to production of sample boxes and customer approval.

High cost

Opening a new mold can cost hundreds of dollars. If the first prototype is not approved, new molds must be made, raising costs exponentially.

Long production cycle

Each iteration requires new molds, adding cost and production time. Not only is this a waste of resources, it can also lead to missed business opportunities.

Poor adaptability

Traditional methods are less flexible in handling custom and low-volume orders, which are increasingly common in the current market landscape.

Advantages of vibrating knife cutting machines

Speed and efficiency

Design, prototyping and production can all be completed in a very limited time frame. If changes are needed, new sample boxes can be produced in ten minutes.

Cost effective

No physical molds are required, saving cost and time on the mold creation and die-cutting process.

Accuracy

The high precision of these machines ensures that once a design is approved, it can go directly into series production, further saving time and resources.

Flexibility

Ideal for large-scale and low-volume production, able to flexibly meet different market needs without the need for expensive molds.

Respond quickly to market needs

By leveraging the speed and flexibility of vibrating knife cutting machines, companies can respond quickly to customer needs and seize business opportunities more effectively.

In today’s fast-paced, demanding packaging industry, the limitations of traditional die-cutting methods are becoming increasingly apparent. Oscillating knife cutters offer a compelling alternative that offers speed, cost-effectiveness and precision. By adopting this technology, packaging companies can significantly enhance their competitiveness and profitability.

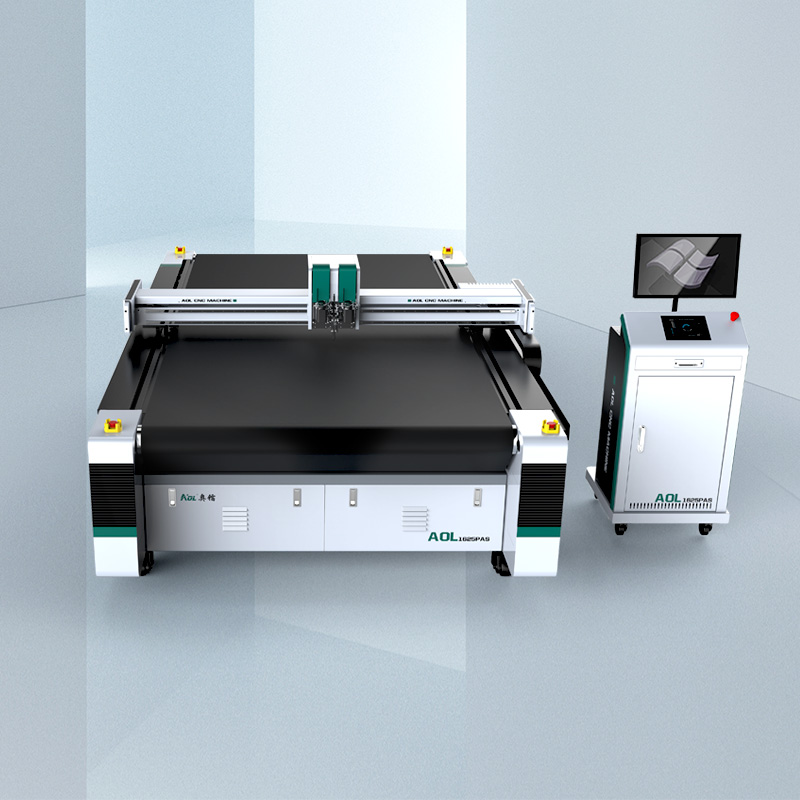

As competition in the consumer market becomes increasingly fierce, ever-changing consumer products are competing for market share. AOL’s CNC cardboard cutters enable manufacturers to frequently change their packaging designs to maintain a competitive advantage. Design cycles have shortened from weeks to days, and production cycles for packaging products have also become shorter. This allows the company to compete on quality and speed of delivery, working to retain its existing customer base while expanding into new ones, ensuring that the entire company operates in a virtuous cycle.

AOL’s CNC cardboard cutting solutions provide packaging companies with a faster, more cost-effective and flexible way to adapt to market demands. The versatility of these machines and their advanced features make them an indispensable asset for companies looking to stay ahead in a highly competitive market.

How to choose CNC cardboard cutting machine supplier

Preliminary testing

It is recommended to send your material to the manufacturer for a test cut. This ensures that the machine you choose is compatible with your materials.

Things to note when choosing the right machine

Determine size according to product

The machine size should match the size of the cardboard or cartons you produce.

For larger boxes (such as shipping cartons), it’s best to use a larger machine.

For smaller boxes such as gift boxes, cigarette boxes, wine boxes, etc., a smaller machine is sufficient.

The difference between a large machine and a small machine can be huge.

Material thickness and type

Choose a machine based on the thickness and toughness of the material.

If the material is thick and hard, the machine will have greater pulling force, potentially shortening its lifespan.

It is crucial to consult with the manufacturer and preferably conduct material testing to ensure compatibility.

Mechanical stability and precision

Take the stability and accuracy of the machine as the basic evaluation criteria.

Visit manufacturers to assess their overall capabilities. Manufacturers should provide on-site demonstrations showing the drawing and cutting processes to evaluate whether they meet your accuracy and cutting requirements.

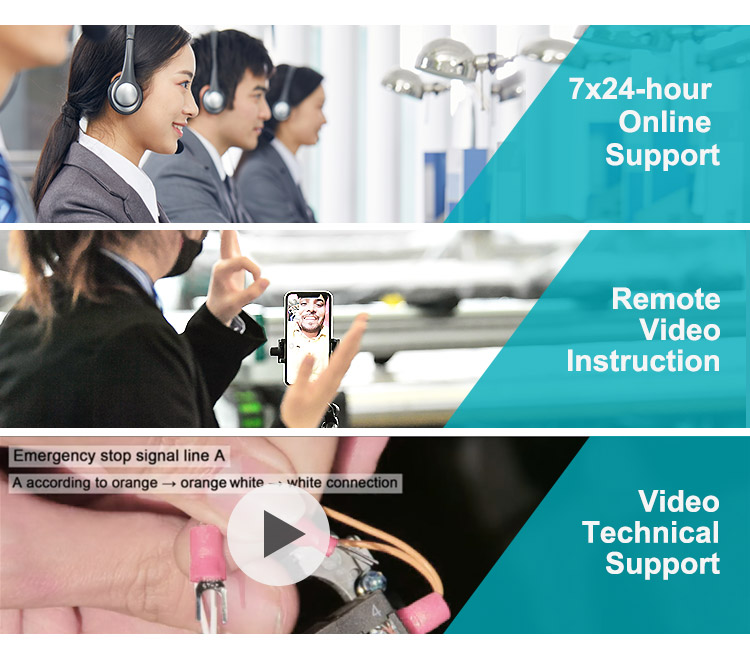

After-sales service and warranty

Choose a manufacturer with complete after-sales service.

AOL provides detailed installation guidance videos and online solutions. In addition to consumables and cutting tools, we offer a three-year warranty on the entire machine.

When choosing a CNC cardboard cutting machine, it is important to conduct preliminary tests, consider the size and type of boxes you produce, evaluate the machine’s mechanical stability and accuracy, and ensure strong after-sales support and warranty. With these factors in mind, you can make an informed decision that best suits your production needs.

AOL carton cutting machines provide seamless, efficient, and high-precision cutting solutions. Their automated capabilities combined with advanced tool selection and high-speed cutting capabilities make them the first choice for businesses looking to optimize their packaging operations.

AOL intelligent blade cutting machine has high precision and high efficiency. Our professional after-sales service can provide automatic cutting solutions for various industries.

For more information, please consult:

Email: [email protected]

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://aollaser.net/