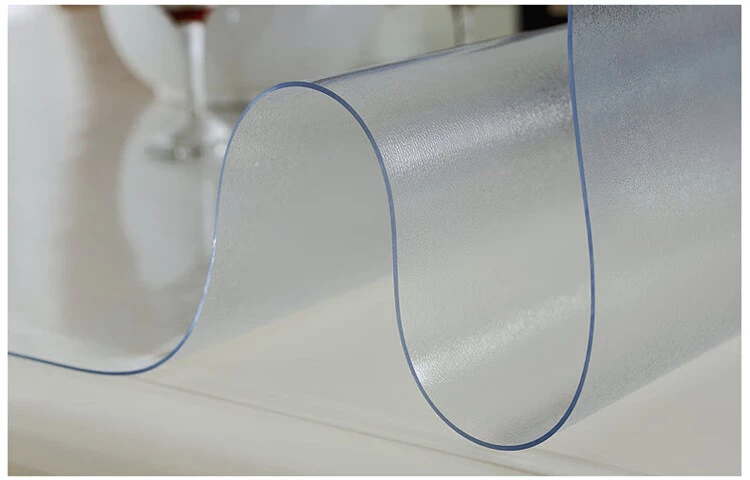

Common crystal panels are made of new healthy and environmentally friendly PVC materials. They are a new generation of high-tech products. They are transparent panels with extremely high transparency. They are suitable for the decoration of dining tables, office desks, coffee tables and other countertops. They are heat-resistant, scalding-resistant, cold-resistant, frost-resistant, and heavy-pressure-resistant. They are also non-toxic and tasteless green decorative materials. The crystal panel materials produced by crystal panel manufacturers replace the shortcomings of traditional glass that is fragile and hurtful, and integrate many advantages into them. They are crystal panels suitable for decoration in various occasions. Crystal panel products have achieved the dual effects of being both beautiful and practical, and of good quality and low price.

CNC crystal rubber sheet cutting machine uses advanced CNC technology and automated control system, combined with precision cutting tools, to accurately cut crystal rubber sheet materials according to design drawings, with the characteristics of high speed, high precision, low noise, etc. The equipment is usually equipped with a vacuum adsorption table, which can firmly fix the rubber sheet to ensure stability and high precision during the cutting process.

The main features of CNC crystal plastic plate cutting machine:

High-precision cutting: The cutting error is usually controlled within ±0.1mm, which is suitable for industries with high cutting accuracy requirements.

High-speed cutting: Supports high-speed automatic cutting, can complete a large number of cutting tasks in a short time, and greatly improves production efficiency.

High degree of automation: Equipped with an intelligent control system, it can perform fully automatic typesetting, path optimization and automated operation to reduce manual intervention.

Adapt to a variety of materials: In addition to crystal plastic sheets, the equipment can also cut various soft film materials, such as PVC, PET, TPU, etc.

Flexible tool configuration: There are rich tool types to support different cutting requirements (such as straight knives, round knives, vibrating knives, etc.).

Environmentally friendly: No excessive noise and dust will be generated during the cutting process, which meets environmental protection requirements.

CNC crystal plastic sheet cutting machine adopts a variety of cutting technologies to ensure the perfect cutting of different types of crystal plastic sheets:

Knife cutting: The traditional knife cutting method is suitable for cutting most crystal plastic sheets. The high-speed cutting of the vibrating knife can effectively avoid the damage of the material.

Laser cutting: For ultra-thin crystal plastic sheets, laser cutting can achieve a more refined cutting effect, with smooth edges, which is suitable for scenes with higher cutting accuracy requirements.

Rotary knife cutting: Cutting by high-speed rotating knife is suitable for medium-thick crystal plastic sheets with high production efficiency.

Although all three types can achieve material cutting, knife cutting is the most popular, environmentally friendly and efficient cutting method. You can watch the video below to learn more!

When choosing a CNC crystal plastic plate cutting machine, the following factors should be considered:

Material type: Different crystal rubber sheet materials (such as hardness, thickness) have different requirements for cutting machines, and appropriate tools and cutting methods should be selected.

Production requirements: If it is mass production, it is recommended to choose equipment with higher cutting speed and higher degree of automation.

Subsequent support: Choose a manufacturer that provides comprehensive after-sales service to ensure long-term and stable operation of the equipment.

If you are a PVC crystal board manufacturer, or have a large demand for PVC cutting, you can learn about AOL’s PVC soft glass cutting machine, which has fast cutting speed, good chamfering effect, high degree of intelligence, automatic feeding and unloading, and worry-free after-sales. For more details, please contact online customer service.