With the widespread application of outdoor artificial turf in sports fields, landscaping and other fields, the market demand for high-quality, customized turf products is growing. The traditional manual cutting method is inefficient and lacks precision, and it is difficult to meet the needs of cutting large quantities and complex shapes. CNC outdoor artificial turf material cutting machines came into being, and with their advantages of high efficiency, precision and automation, they have become a revolutionary tool in the artificial turf production industry.

What are the core components of CNC outdoor artificial turf material cutting machine?

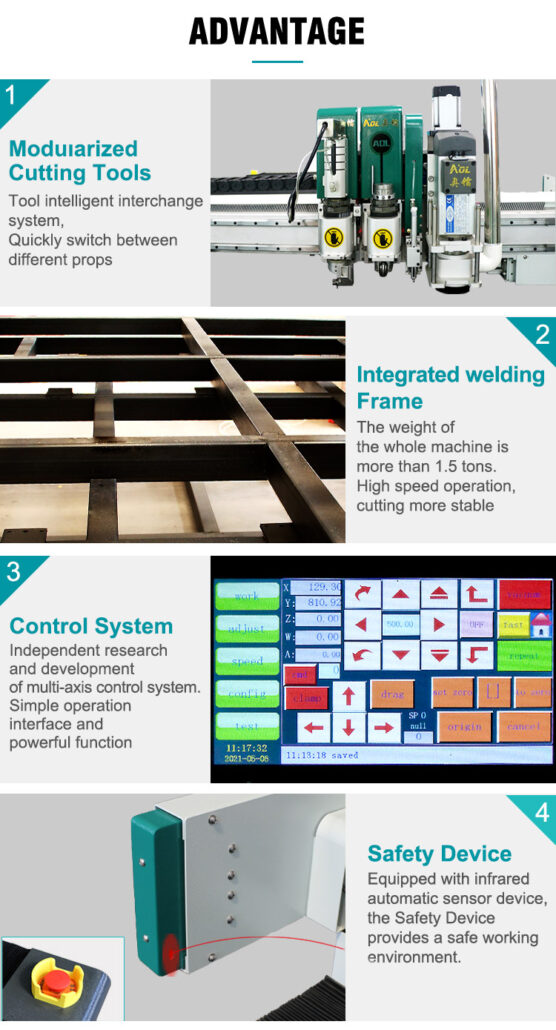

CNC system: As the brain of the equipment, it is responsible for receiving and processing CAD drawing data, controlling the cutting path and speed.

Cutting platform: used to fix and support artificial turf materials to ensure stability during the cutting process.

Cutting head: According to the material characteristics, different types of cutting heads such as vibration knives and circular knives can be selected to achieve efficient cutting.

Drive system: Control the movement of the cutting head in the X, Y, and Z axis directions to ensure cutting accuracy.

Vacuum adsorption system: Fix the material to prevent displacement during cutting.

The core advantages of CNC outdoor artificial turf material cutting machine:

High-precision cutting: The CNC control system ensures the accuracy of the cutting path, and the error can be controlled at the millimeter level, meeting the needs of complex shapes and high-precision cutting.

High-efficiency production: Automated cutting greatly improves production efficiency, which is several times that of traditional manual cutting, and is especially suitable for mass production.

Diversified cutting: It can easily cope with a variety of cutting needs such as straight lines, curves, circles, and special shapes, meeting the customized requirements of different application scenarios.

Material saving: By optimizing the cutting path, maximize material utilization and reduce production costs.

Easy operation: The user-friendly operating interface and automation functions reduce the technical requirements for operators.

Safe and reliable: Equipped with complete safety protection devices to ensure safe operation.

Application areas of CNC outdoor artificial turf material cutting machine:

Sports venues: Precisely cut the lawns of football fields, basketball courts, tennis courts and other sports venues to ensure that the size and shape meet the standards.

Landscaping: Used in landscaping projects such as parks and courtyards to cut lawns of various shapes to enhance the aesthetics.

Indoor decoration: Suitable for decoration of indoor walls, roofs, etc., cutting personalized patterns and shapes.

Other fields: It can also be used for cutting in industries such as carpets and advertising materials.

CNC outdoor artificial turf material cutting machines have become an important tool in the artificial turf production industry with their advantages of high efficiency, precision and automation. With the advancement of technology and the growth of market demand, CNC cutting machines will play a greater role in the future, driving the artificial turf industry towards higher quality and more environmentally friendly development.

After learning so much, have you already had a detailed understanding of cutting equipment? Do you still have questions that need to be answered? We are very happy to help you! Just click the “Contact Us” button here, leave your contact information and the material to be cut, and our professional team will get in touch with you as soon as possible to provide you with a personalized solution.