Despite rapid advances in composite part manufacturing technology, many composite manufacturers still cut reinforcements by hand. While the use of automated material cutting is growing, more manufacturers could benefit from adopting this efficient and affordable technology.

Automated cutting of reinforced composites has become standard in the aerospace and marine industries. Why? Because the latest technology can significantly reduce material waste, eliminate unnecessary labor, and improve quality. It will also increase production. If you’re not already using automated cutting, now’s the time to re-examine your cutting processes and see what this technology can do for your business.

Benefits of automated cutting equipment for reinforced composite materials:

There are four main reasons to implement enhanced composite automation equipment: reduce labor, improve material utilization, improve quality, and increase efficiency and flexibility.

Reduced Labor – Machine cutting is faster and more accurate than manual cutting, even with static table machines where the operator manually positions the material to be cut. Conveyor systems automatically feed and spread the material. These systems require minimal labor to operate and can switch from one job to another in minutes.

Improved Material Utilization – Because automated cutting machines are so precise and repeatable, errors and waste common in manual cutting can be reduced. In addition, easy-to-use nesting software can automatically arrange the formwork shapes in the most material-efficient way to fit the size of the material being cut. These factors combine to reduce material waste by up to 25%.

Quality – Automated cutting machines are so precise that the quality of the final molded product is more consistent. This becomes critical as part complexity increases.

Efficiency Leads to Flexibility – The high speed of automated cutting increases production throughput, and cutting can be done closer to the time of spreading, or in some cases even simultaneously. This leads to greater flexibility in scheduling. It can also reduce the deterioration of materials that require refrigeration and have a limited shelf life at room temperature.

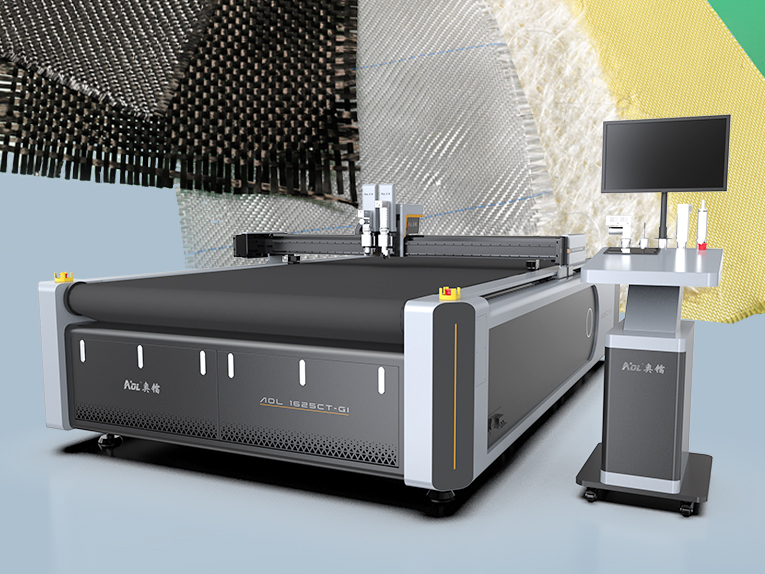

When analyzing the ROI of an automated cutting investment, some factors can be difficult to predict or measure. AOL CNC offers a free test cut evaluation using your material and pattern and/or cut files to capture the machine’s speed, material efficiency and recommended configuration prior to investment. This value-added service provides detailed feedback and optional video footage of the recommended process and will play an important role in your ROI calculations.

With this information, you can now prove the value proposition of enhanced composite automated cutting compared to existing processes with some real numbers, and have a high degree of confidence that the promised outcomes of your investment are real.

If you are cutting or wasting a lot of material, it’s time to take a fresh look at automated cutting technology. Automation will reduce your labor costs, improve material utilization, and result in consistently high-quality cuts. It’s an option you can’t afford to ignore.

For more information, please consult:

Email: [email protected]

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://aollaser.net/