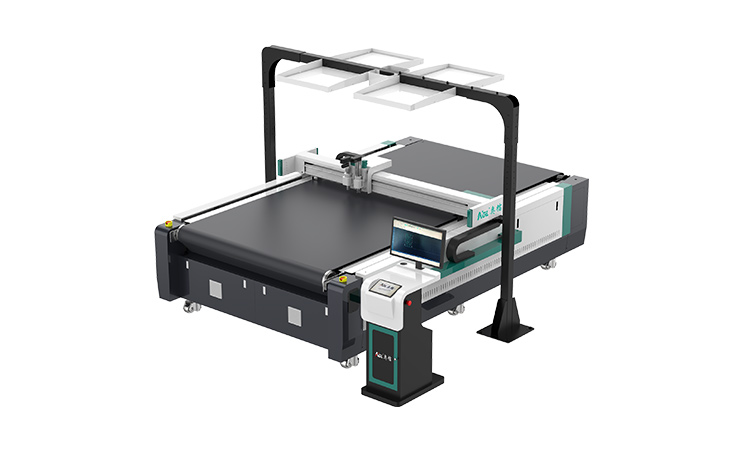

Leather & Shoes CNC cutter

CNC Leather Cutting Machine for Sale

Accuracy in dimensions and processing are extremely important to improve quality and finishing for both small and large leather goods. Close to its production capacity and reliability, such an accuracy has made AOL become the most important partner of leather goods manufacturers.

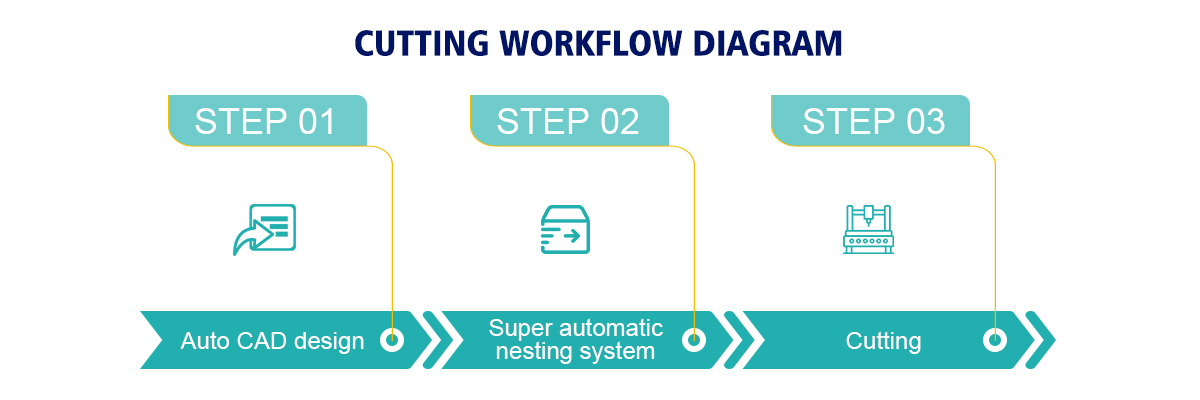

AOL digital leather cutting machines eliminate the need for expensive dies and reduce the need for manpower, all while processing leather, sole, lining, and pattern materials efficiently and at the highest levels of quality. Superior cutting performance, low operating costs, and optimized workflow guarantee a quick return on investment.