In modern manufacturing, digital cutting machines have become a key technology that has greatly improved the precision and efficiency of the production process. These machines use advanced computer control systems to achieve complex designs and cuts with unparalleled precision. Among them, CNC knife cutting machines are particularly known for their ability to process a variety of materials such as cardboard, leather and gaskets with extremely high precision.

Rockwool panels are becoming increasingly popular as an innovative solution for thermal insulation in interior design. Made of high-temperature glass fiber, these panels are an environmentally friendly choice and are widely used in the construction and industrial fields. For example, they are used in building exterior wall insulation, pipe insulation, tank insulation, thermal insulation and sound insulation in industries such as ships, aviation, and trains.

This article explores the connection between AOL CNC cutting machine and rock wool material. If you want to know more, please continue reading patiently!

Digital cutters represent a significant advancement in the precision and efficiency of material shaping and assembly. At the heart of this technology is the CNC (Computer Numerical Control) cutter, a versatile tool designed to process a wide range of materials with unparalleled precision.

Working principle of digital cutting machine:

CNC Technology: These machines use CNC technology, where computer-aided design (CAD) software controls the cutting process, ensuring that every cut is made exactly to digital specifications.

Mechanism: The main mechanism consists of a movable knife or blade that follows a programmed path. This allows complex designs and patterns to be created without any human intervention.

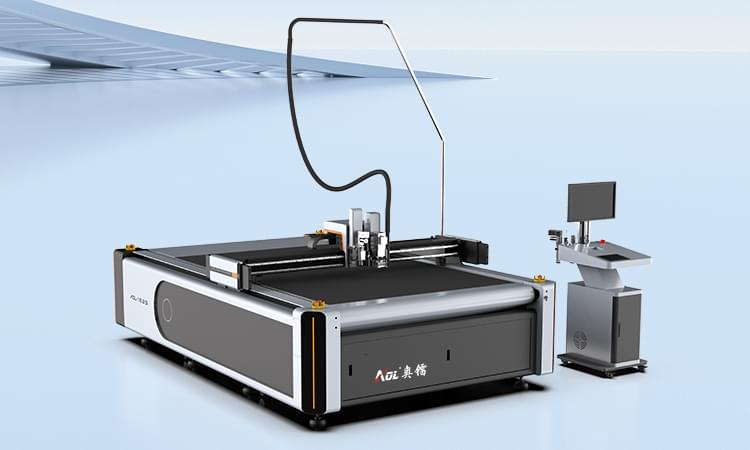

The main features of the rock wool material CNC vibration knife cutting machine:

Table size: The table measures 1600*2500mm, which can accommodate large pieces of rock wool materials, allowing large projects to be processed efficiently.

Precision and speed: CNC technology ensures that cutting is both precise and fast, which is essential to maintaining quality and productivity in a manufacturing environment.

Versatility: The ability to process not only rock wool materials, but also a variety of other flexible materials makes it a versatile choice for a variety of cutting needs.

Ease of use: The user-friendly interface design simplifies operation and reduces the learning curve associated with machine setup and control.

The AOL CNC cutting machine combines precision, speed and versatility, making it an excellent choice for professionals who want to improve their cutting capabilities, especially in the production of rock wool materials.

Characteristics of rock wool materials:

1. Good fireproof performance: Rock wool uses basalt and other minerals as raw materials. It does not burn when exposed to open flames. It belongs to Class A thermal insulation material and is suitable for buildings, fire doors, smoke exhaust systems and other fields.

2. Thermal insulation: Rock wool has good thermal insulation performance as a thermal insulation material. It is widely used in building exterior walls, roofs, industrial pipelines, kilns and other fields.

3. Sound absorption and noise reduction: Rock wool belongs to fiber structure and can reduce environmental noise. Rock wool sound-absorbing panels are used for indoor ceilings and can absorb noise very well.

4. Easy to cut: Rock wool is light and easy to construct.

5. Corrosion resistance: Rock wool has good corrosion resistance and is suitable for various pipeline insulation. It protects pipelines and has a long-lasting application.

The future development trend of rock wool material CNC vibration knife cutting machine:

Intelligence

Combined with artificial intelligence technology, the future CNC cutting system can achieve adaptive optimization and real-time monitoring, further improving processing quality and efficiency.

Green and environmental protection

Adopt more environmentally friendly cutting processes to reduce dust, noise and waste emissions, in line with sustainable development requirements.

Multi-material compatibility

Further improvement of technology will enable the equipment to adapt to more types of composite materials, providing possibilities for the combined processing of rock wool and other materials.

The application of CNC cutting technology in the processing of rock wool materials not only improves processing accuracy and efficiency, but also significantly reduces production costs and safety hazards. With the continuous upgrading of technology, its application scope will be further expanded, providing strong support for the development of the rock wool processing industry.Contact us for a quote!