The automotive leather market is expected to continue to expand, according to in-depth market trend analysis by a professional automotive industry research institute.

It is expected that the amount of leather used in each passenger car will increase by 3% each year. By 2025, the amount used in each car is expected to reach 22.5 square feet, and the domestic passenger car leather market size is expected to exceed 10 billion yuan!

Under the wave of independent brands and new forces, the domestic automobile market is ushering in a revolution in leather interior upgrades.

With the strong rise of domestic brands and the continuous launch of mid-to-high-end models, the domestic automobile market is experiencing a revolution in leather interiors. Leather interiors have become standard equipment for more and more models. This trend is particularly evident in new energy vehicles with a price of more than 200,000 yuan, where all models have leather seats as standard equipment.

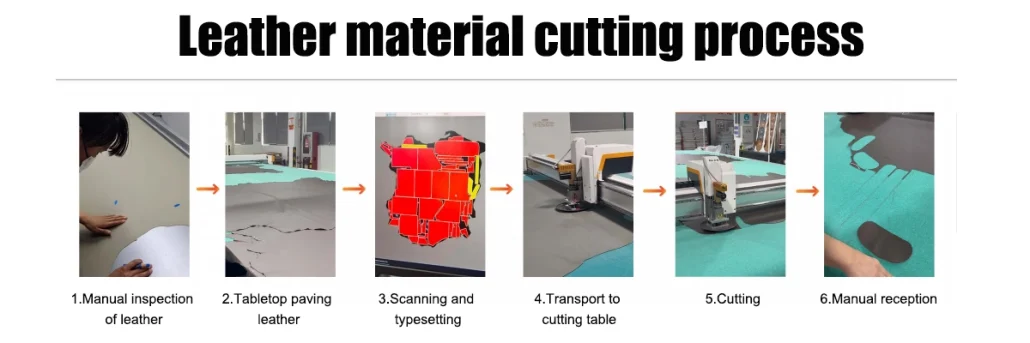

However, due to the changes in user needs and material types, manufacturers face challenges brought by production complexity, especially in the leather nesting and cutting process. This process not only requires superb manual skills and time, but is also prone to errors, often leading to unnecessary production bottlenecks and reduced capacity. Considering the high cost of leather materials themselves, maximizing the cost of every inch of leather has become a major challenge.

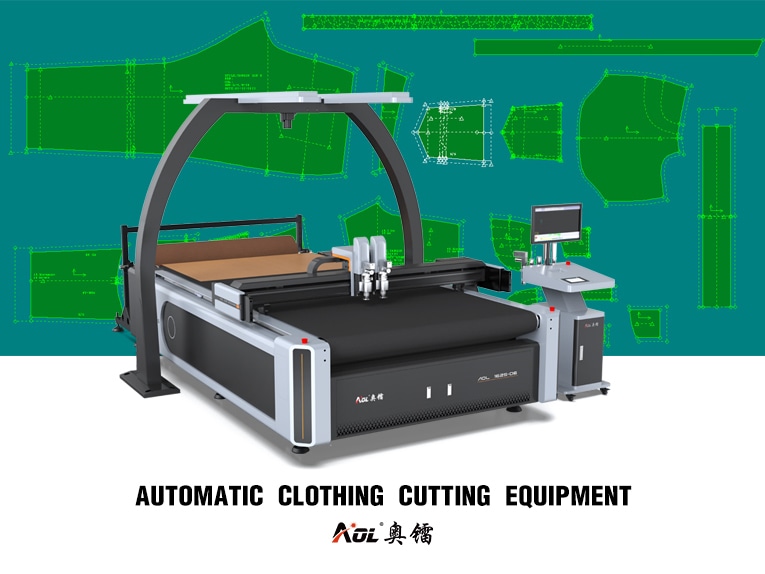

In response to this challenge, AOL launched a set of solutions for leather nesting and cutting in the automotive interior industry. The solution realizes digital operation, reduces labor, minimizes material waste, simplifies cutting operations, and improves product quality, laying a solid foundation for automakers to improve production efficiency and profitability.

AOL’s digital solution uses a self-developed algorithm with the highest material utilization rate of over 85%, achieving the best nesting effect in the most material-saving way.

AOL automotive interior digital leather layout and cutting solution has the following advantages:

1. From leather nesting to cutting:

Our self-developed software can help you significantly reduce fabric waste.

2. Digitally connected editing room:

Accelerate your pace towards smart and green manufacturing.

3. Improve leather utilization:

The intelligent nesting system improves utilization by 2-10% compared to competitors.

4. Higher production efficiency:

The efficiency of digital leather cutting is 2-3 times that of traditional cutting methods, greatly saving labor costs.

5. Real-time data dashboard:

Perform real-time data monitoring and management.

We also provide customers with comprehensive service guarantees. From basic operations, equipment installation, personnel training, remote services, production process support to software upgrades and improvements, AOL is dedicated to serving you. We are committed to helping you solve various production problems, ensure smooth production operation and save overall costs.

In the design and manufacturing process of automotive interiors in the leather era, the application of digital technology provides automakers with great cost savings. From the design stage to production, inventory management, consumer customization, after-sales service and environmental innovation, digital technology runs through the entire life cycle of automotive interiors. With the continuous advancement of technology, automakers can not only improve production efficiency and reduce costs, but also improve product quality and consumer satisfaction, which will drive the automotive industry to a more advantageous position in future competition. If you want to learn more, please click here to contact us, and we will answer you as soon as possible!