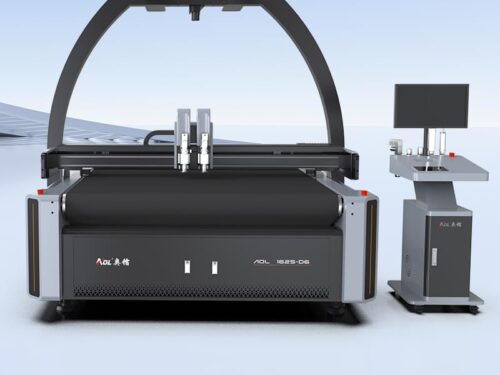

What is a CNC sofa fabric cutting machine?

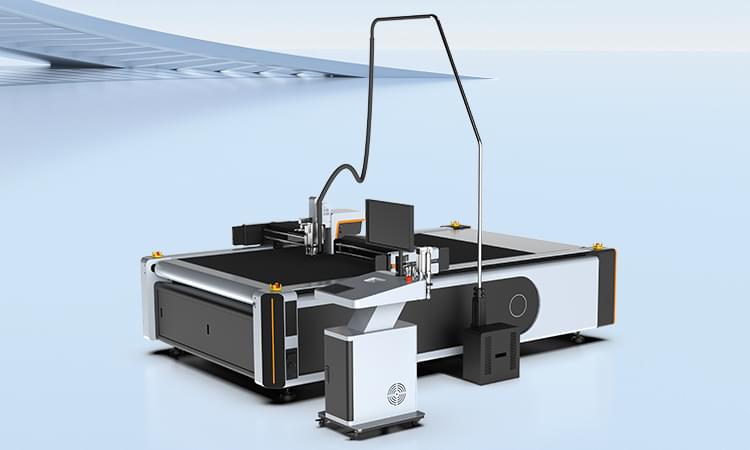

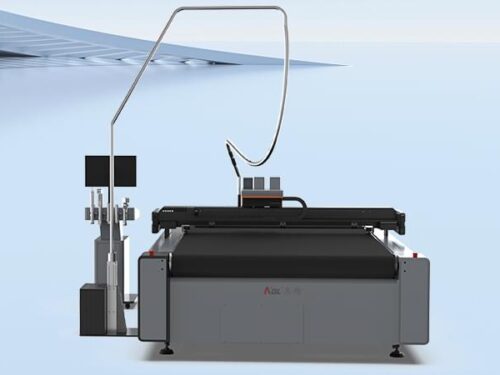

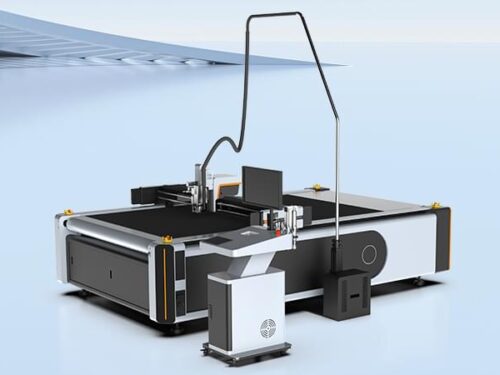

CNC sofa fabric and leather cutting machines use computer software to control the movement of cutting tools along multiple axes (usually X, Y and Z). This allows for precise and repeatable cutting of materials, reducing waste and increasing productivity in furniture manufacturing.

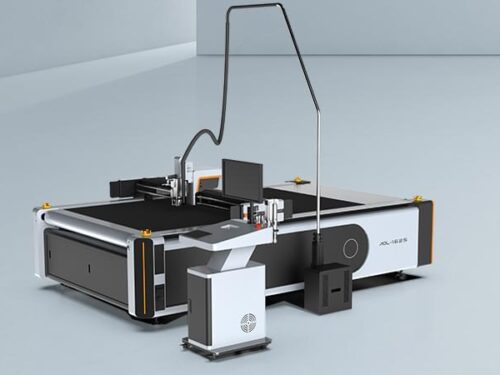

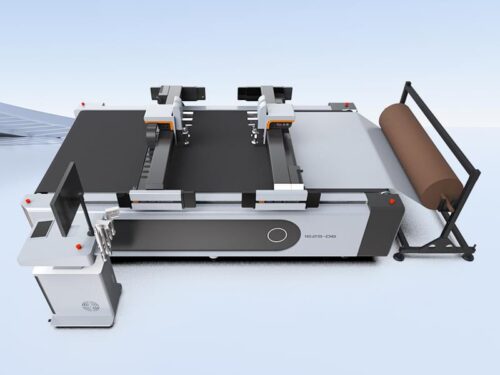

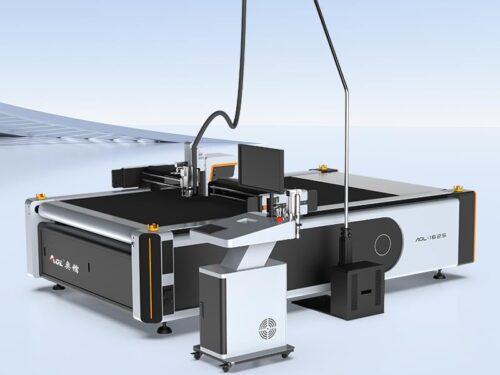

The soft sofa fabric cutting machine uses CNC circular knife cutting technology and is equipped with a servo motor. The fastest processing speed is 2000mm/s, which can quickly cut all kinds of sofa fabrics. In order to achieve continuous and automatic cutting of sofa fabrics, the sofa fabric cutting machine is equipped with an automatic feeding platform with vacuum adsorption function and a precise automatic feeding system to achieve automatic and continuous cutting of sofa fabrics.

The automatic cutting solution for soft sofa fabrics consists of three systems: sofa piece data intelligent management system, sofa CAD intelligent nesting software, and fabric automatic cutting machine. Help sofa factories establish electronic data, and use super nesting software to quickly layout, improve fabric utilization, and then use CNC fabric cutting machines to automatically cut. Make sofa cover cutting work super simple, solve the dependence of sofa cutting on skilled cutting workers, and one machine can replace 3-4 workers.

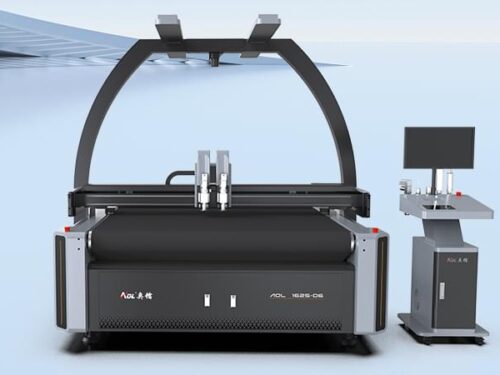

Various parameters of sofa fabric leather CNC cutting machine:

| Technical parameters / model | AOL1625 | AOL1825 | AOL2125 | Accept special model customization | ||

|---|---|---|---|---|---|---|

| Effective working area | 1600x2500mm | 1800x2500mm | 2100X2500 | |||

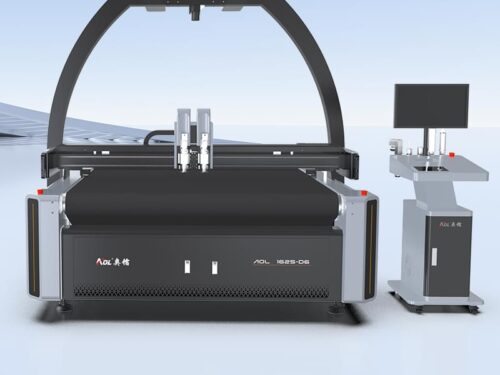

| Multi-head optional | Double head optional efficiency doubled, double gantry optional, double head mutual shift optional, length can be customized | |||||

| Multi-function tool | Vibrating knife full cutting, high power active round knife, punching tool, pneumatic knife, multi-layer knife | |||||

| safety devices | Safety devices use infrared sensing, safe and reliable | |||||

| Cutting speed | 200-2000mm/s | |||||

| Cutting thickness | ≤50mm Other thicknesses can be customized according to the material | |||||

| Applicable materials | foam, vinyl, cardboard, paper, lable, fabric, gasket,cotton, linen, silk, blends, fibers, leather, etc. | |||||

| Material fixing method | Vacuum partition adsorption | |||||

| Transmission port | Network port | |||||

| Transmission system | Imported servo motor, linear linear guide, timing belt, lead screw | |||||

| rated power | 11kw | |||||

| Rated voltage | 380V±10%/220V±10% Optional | |||||

| Control System | Chinese and English LCD touch screen | |||||

| Operating environment | Operating environment Temperature 0-40°C Humidity 20%-80%RH | |||||

| Software | Automatic nesting software, template entry software(Optional) | |||||

| Support file format | AI、PLT、DXF、CDRetc | |||||

| Overall size | 3570x2290x1165mm | 3570x2500x1165mm | 3570x25800x1165mm | |||

Main features of CNC sofa fabric and leather cutting machine:

High Precision: Enables precise cutting of complex patterns and designs.

Versatility: Cuts a wide range of materials including fabric, leather, foam and vinyl.

Automation: Reduces manual labor and increases efficiency by automating the cutting process.

Material Optimization: Minimizes waste by optimizing material usage.

Ease of Use: User-friendly software and controls for beginners and professionals.

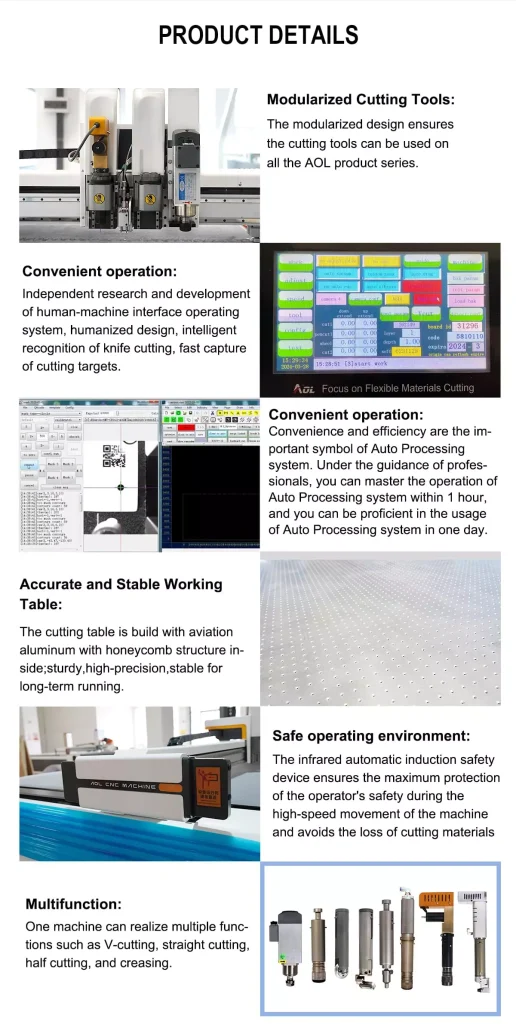

Detailed information of sofa fabric leather CNC cutting machine:

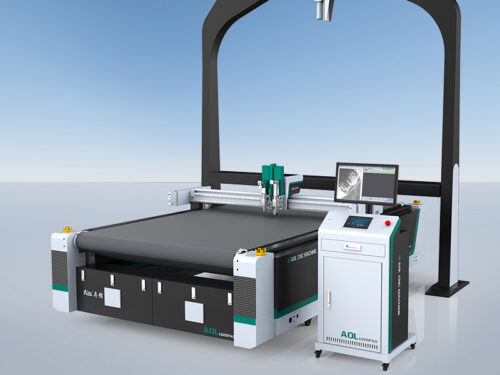

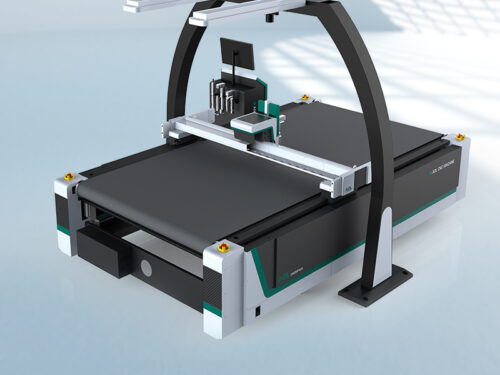

Multiple tool combinations:

Configure different types of tools to meet the automatic cutting of single-layer or multi-layer fabrics. Equipped with movable circular knives, V-shaped knives or vibrating knives, it can automatically and accurately cut different materials such as leather, knitted fabrics, woven fabrics, composite fabrics, etc.

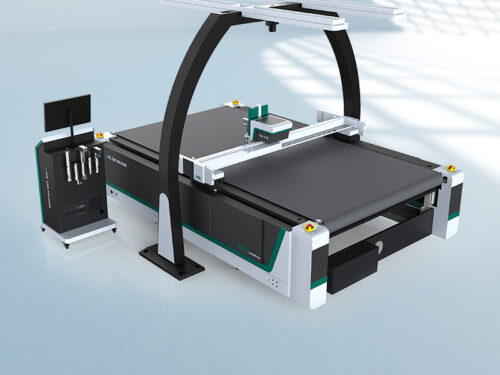

Vacuum adsorption platform:

Optional partition adsorption, 8-48 adsorption partitions, can follow adsorption, the material is fixed on the cutting platform during the cutting process to ensure accurate cutting.

Touch screen operation panel:

Color touch control panel, the operation interface is more intuitive, you can directly input processing data, set processing speed and knife depth, support automatic screen protection, protect processing data.

Precision rack transmission:

Servo rack transmission mode, Y axis is driven by dual servo motors, strong power and stable performance.

Integral welded bed:

The machine bed adopts a welded structure to ensure accuracy and life. Square tube welding integrated molding, high temperature heat treatment, milling machine finishing.

Automatic feeding system:

The automatic feeding system is used to realize automatic conveying and automatic deviation correction of fabrics, ensuring the accuracy of feeding and avoiding the stretching deformation of elastic fabrics during feeding. Textile rolls of different diameters can be placed, and the feeding speed can be set according to the weight of the fabric.

Competition in the sofa manufacturing industry is becoming increasingly fierce. How to make products more competitive is a question that many sofa factory owners are thinking about. In order to win more market share, many sofa manufacturers need to meet customers’ customized requirements for sofa size, style, and color, and complete these tasks in the shortest possible time. Meeting these market requirements will bring great difficulties to production, which requires more cutting workers. However, many sofa factories are faced with the problems of difficulty in recruiting workers, difficult management, and high costs. Moreover, manual cutting has the problems of serious material waste and low efficiency. So how to meet market requirements and solve the problem of difficulty in recruiting workers? This requires a more flexible, intelligent, and efficient processing method.

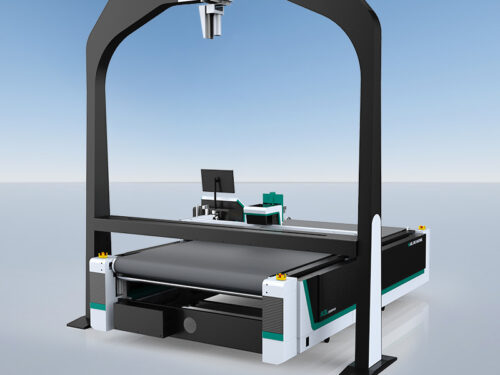

Six advantages of CNC circular knife cutting machine for cutting sofa fabrics:

1. Realize automated processing and reduce production dependence on personnel

Equipped with a precise automatic feeding system, the fabric can be automatically transported during the continuous cutting process to ensure fast and accurate continuous processing. Only one person is needed to operate the machine, reducing labor costs.

2. Improve work efficiency and shorten the delivery cycle

The sofa fabric cutting machine has a cutting speed of 1500mm/s and can produce 20 sets of sofas in 8 hours (custom sofa single-layer fabric cutting), which can replace 4-5 cutting workers.

3. Quick nesting in 1 minute to improve fabric utilization

The CNC fabric cutting machine comes with a super nesting system, which can provide customers with the most perfect nesting solution within one minute, saving 30-40 minutes compared to manual nesting, and the material utilization rate can be increased by more than 10%.

4. Meet customer sofa customization needs

The sofa fabric cutting machine is computer-controlled to digitally manage sofa data. Customers can quickly modify the size, quantity, and style of the sofa in the software to meet the production of customized sofas.

5. The machine is equipped with an automated cutting system to meet the production of sofas of different sizes.

The sofa fabric cutting machine uses an automatic feeding platform, which only requires 3MX6M of installation space to complete the processing of super-long materials, and the theoretical processing length is unlimited.

6. The machine operation and installation are super simple.

Provide customers with detailed teaching videos, so that customers can quickly master the software operation in less than a day without any software foundation.

Digital cutting machines are essential tools in many industries such as apparel manufacturing, packaging, etc. They offer a level of precision and accuracy that manual cutting tools cannot match. However, many people still do not know how these machines work.

Computer graphics are used, and after internal data processing, the data is transmitted to the machine control card. The control card then sends a command pulse signal to the servo drive. The drive drives the servo motor to move to achieve the movement of the machine, and at the same time sends a signal to the cutting tool to cut the raw materials.

Digital cutters have revolutionized the way many industries cut, allowing them to increase productivity, save time, and reduce waste. They offer unparalleled accuracy and precision, making them an essential tool for many different manufacturing industries. With the advantages these cutters offer, it’s easy to see why they have become a necessary investment for any business that needs efficient and reliable cutting equipment.

If you want to know more, please click here to leave a message and contact us. We will give you a detailed answer as soon as possible!

Reviews

There are no reviews yet.