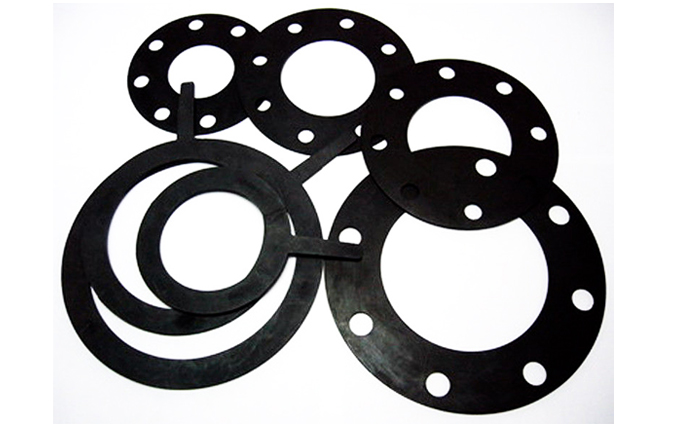

Rubber gaskets are widely used in industries that require precision and durability. But cutting them is not as simple as it seems. Traditional methods such as die cutting, laser cutting or punching machines often result in:

Jagged edges that require secondary processing.

Heat-related damage, such as cracks or deformation.

Inconsistent dimensions, especially with custom shapes.

Dust and fumes that make for less-than-ideal working conditions.

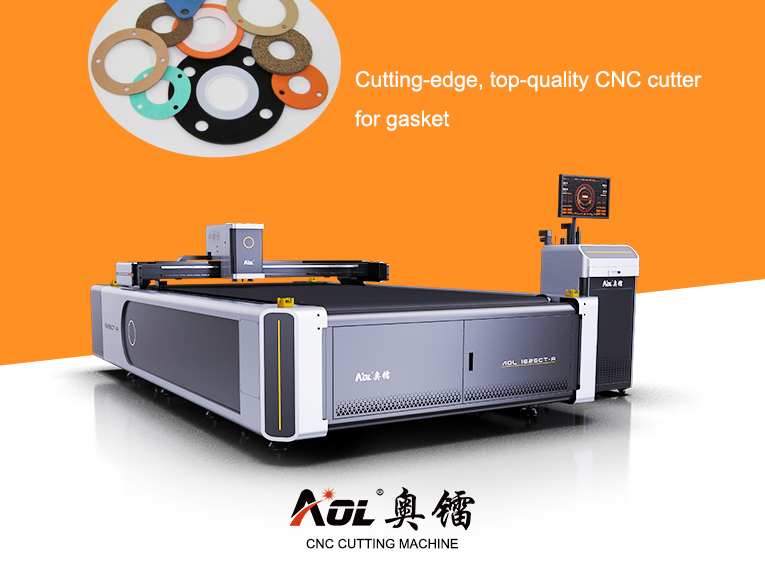

What if there was a solution that eliminated all of these issues while saving you time and money? That’s where the AOLCNC rubber gasket cutting machine comes in.

What are the advantages of AOL CNC rubber gasket cutting machine?

1. No heat, no damage:

Unlike hot cutting methods, AOL CNC machines use cold cutting technology. This means no heat damage, no cracks, and no material aging.

2. Perfect edges:

Say goodbye to jagged edges and burrs. Our machines deliver smooth, clean cuts every time.

3. Freedom of shape:

Whether you need a round, serrated, or completely custom shape, this machine can handle it with ease. There are no limits to your creativity.

4. Dust-free and environmentally friendly:

Cutting rubber typically creates dust and unpleasant fumes, but with an AOL CNC, these fumes are not produced. Our built-in dust collection system keeps your workspace clean and safe.

5. Precision and consistency:

From small shims to large sheets, every cut is perfectly uniform. No more worrying about inconsistent sizes.

6. Optimal efficiency:

With fast cutting speeds and the ability to handle multiple tools in one setup, you can easily complete production and reduce costs.

How to improve its accuracy and efficiency directly affects product quality and production costs. The following is a detailed introduction to the improvement solutions in these two aspects!

Cutting accuracy improvement plan:

1. High-precision transmission system

Adopt ball screw + linear guide structure to improve the smoothness of movement and repeatability of positioning accuracy.

Use servo motor instead of traditional stepper motor to achieve more precise displacement control.

Equipped with high-resolution encoder to ensure controllable movement accuracy of each step.

2. High-precision tools and cutting methods

Adopt high-precision CNC control system to ensure high-precision cutting of complex graphics.

Equipped with automatic alignment recognition system (such as visual recognition and laser positioning) to reduce human errors.

Use intelligent compensation algorithm to correct the elastic retraction error of rubber materials.

3. Precision control system

Adopt high-precision CNC control system to ensure high-precision cutting of complex graphics.

Equipped with automatic alignment recognition system (such as visual recognition and laser positioning) to reduce human errors.

Use intelligent compensation algorithm to correct the elastic retraction error of rubber materials.

Solutions to optimize and improve production efficiency:

1. Multi-head cutting

Configure a multi-head structure to cut multiple parts simultaneously and increase production.

Combined with an automatic tool change system, it can adapt to processing requirements of different shapes and sizes.

2. High-speed cutting mode

Adopt a high-speed servo system to increase the speed of the tool head movement.

Combined with an intelligent path optimization algorithm, reduce invalid movement and improve processing efficiency.

Adopt an automatic feeding and layout optimization system to reduce material waste and improve production efficiency.

3. Automation and intelligent integration

Adopt a fully automatic loading and unloading system to reduce manual intervention and improve production continuity.

Introduce a machine vision inspection system to automatically detect cutting quality and reduce defective rates.

Combined with MES (manufacturing execution system), real-time production monitoring and data analysis can be achieved.

With AOL CNC rubber gasket cutting machine, you will completely change the way you cut rubber and sealing materials. Whether you are mass producing or processing custom orders, by adopting high-precision transmission system, high-speed intelligent cutting method and automatic control technology, enterprises can reduce production costs, improve product quality and enhance market competitiveness.

Still have questions? Contact us today – we’d be happy to show you why AOL CNC is the cutting-edge solution you’ve been waiting for.