We often see pieces of fabric on the floor of the workshop. These pieces pile up higher and higher, and the final disposal method is to throw them away. As a manufacturer of AOL CNC machinery and equipment, this inefficient cutting method is absolutely not allowed!

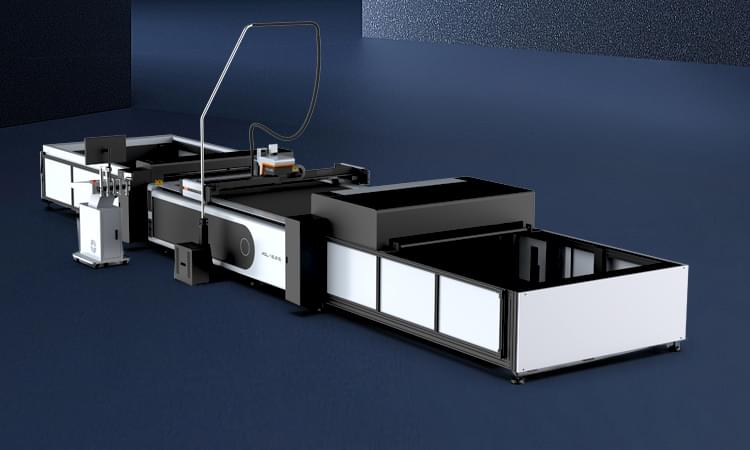

Automatic fabric cutting machines are changing the paradigm of cutting. This technological marvel speeds up production and reduces waste, making your upholstered sofa manufacturing process smoother than ever before.

How automatic fabric cutting machines improve efficiency:

When we introduced automated fabric cutting machines into our process, the first thing we noticed was speed. These machines can cut fabric in a fraction of the time it would take manually. With precise computer control, they can handle complex patterns with ease.

Reduce waste with an automatic fabric cutter:

Fabric is actually not cheap, and you may not feel bad if you waste a little, but after saving a lot, it will be a big sum of money. The automatic fabric cutting machine optimizes the pattern layout on the fabric to ensure the least waste.

Since switching to automatic fabric cutting machines, we have seen fabric waste reduced by up to 30%. In the long run, this is a significant saving. Additionally, less waste means a greener operation.

Frequently asked questions about automatic fabric cutting machines:

How do these machines actually speed up production?

They automate the cutting process, eliminating the need for manual measuring and cutting. The machine’s precision reduces errors, so you spend less time correcting mistakes.

Can they significantly reduce fabric waste?

Of course you can. The software will calculate the most efficient way to cut your pattern to make the most of your fabric.

Are they difficult to integrate into my current setup?

It’s not difficult at all. Most machines are designed to fit into existing workflows with minimal disruption.

Is training provided? Will my team need weeks of coaching?

Surprisingly, no. The user-friendly interface means your team can be up and running in just a few days.

Can they handle complex designs with ease?

Yes, they can accurately replicate complex patterns, which would be challenging and time-consuming to do manually.

Is it worth investing in a machine?

When you factor in the time saved and the reduced waste, the return on investment is typically seen within a year.

In addition to increasing efficiency and reducing waste, these machines also improve product quality. Consistent, precise cuts mean your upholstered sofas will turn out perfectly every time. Customers notice these details, which can set you apart from your competitors.

An automated fabric cutting machine is more than just a technological upgrade, it’s a strategic move to increase efficiency and reduce costs. Trust me, your bottom line will thank you. Plus, you’ll sleep easier knowing you’re running a leaner, greener operation.

AOL intelligent blade cutting machine has high precision and high efficiency. Our professional after-sales service can provide automatic cutting solutions for various industries.

For more information, please consult:

Email: [email protected]

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://aollaser.net/