Automatic CNC carpet cutting machine is an efficient and precise equipment, which is widely used in carpet processing and production, especially in large-scale industrial production, and can automatically complete the task of carpet cutting. Compared with traditional manual or semi-automatic carpet cutting machines, automatic CNC carpet cutting machine adopts computer numerical control technology, has a high level of automation and flexibility, can improve production efficiency while ensuring cutting quality.

The carpet cutter is an efficient carpet cutting equipment. It uses a high-frequency vibration knife to cut a series of carpets, such as bathroom carpets, kitchen carpets, sofa carpets, door mats, absorbent mats, coffee table mats, stair mats, elevator mats, tapestries, etc.

Carpets are divided into many types, pvc carpets, coil carpets, chenille carpets, plush carpets, tufted carpets, all of which can be cut by the carpet cutter, just use different cutting tools.

CNC Carpet Cutting Machine Tools:

1. Pneumatic tool: Some spliced carpets are relatively hard, or some carpets have hard PVC at the bottom. You can choose this kind of tool, which has a large amplitude, high power and better cutting effect.

2. Vibrating knife tool: suitable for cutting carpets such as PVC carpets, bathroom carpets, kitchen carpets, roll carpets, etc.

3. Round knife: suitable for cutting some soft carpets, such as chenille carpets, plush carpets and some other breathable and soft materials. With a specially customized pressing plate, plush carpets can be cut without damaging the fur.

4. Top camera: suitable for edge cutting of irregular patterns, or patterns with unclear edge patterns. By shooting printed or woven carpets with a camera, the software automatically extracts the pattern outline, the system automatically calculates, and accurately cuts the material.

5. Laser line positioning: cross red light, laser-assisted marking positioning and edges, improve cutting accuracy, and easy installation.

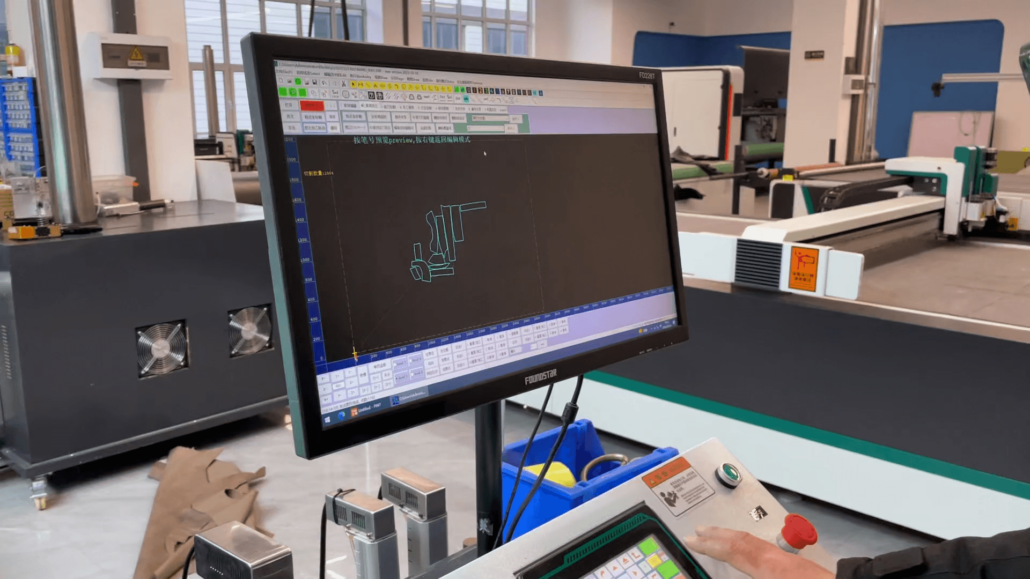

Working principle of automatic CNC carpet cutting machine:

Setting: Through the CNC system, the operator can input parameters such as the cutting size, shape, quantity, etc. of the carpet. It can be programmed according to the pattern, design requirements or specific production tasks of the carpet.

Positioning and cutting: The CNC system controls the cutting machine’s tool to move along the predetermined path according to the programming instructions. The system will accurately control the speed, depth and direction of the tool to achieve the cutting of complex shapes. During the cutting process, the tool contacts the surface of the carpet and cuts as needed.

Automated operation: The equipment can complete the entire cutting process without human intervention through automatic detection, calibration and adjustment.

Cutting mode: The equipment supports multiple cutting modes, such as straight cutting, curve cutting, multi-angle cutting, etc., which can meet different design requirements.

Advantages of carpet cutting machine:

Precision and Accuracy: Using a computer control system allows for extremely precise cutting. Cutting accuracy can be as precise as a few millimeters or less, depending on the capabilities of the machine. This precision is critical for applications that require precise size and shape, such as the production of custom-sized carpets for high-end interiors or precision-cut felt components for industrial applications.

Increased productivity: These machines can significantly increase productivity compared to manual cutting methods. They can operate at high speeds, cutting multiple parts continuously without the need for frequent breaks. The automated nature of the process also reduces the time required for setup and adjustments between cuts, allowing for efficient mass production of felt and carpet products.

Versatility: Automatic felt/carpet cutting machines can handle a variety of cutting patterns and shapes. They can produce straight cuts, curved cuts, complex geometries, and even intricate designs. This versatility makes them suitable for use in different industries, including home furnishings, automotive interiors and industrial applications.

Reduce material waste: Precise cutting machines help minimize material waste. By precisely following a programmed cutting path, the machine can optimize the use of felt or carpet material, cutting the pieces in a way that maximizes yield from a given roll of material.

Consistent quality: The machine can cut multiple parts with consistent cut quality. Because the cutting process is automated and controlled by a set of programmed instructions, each cut piece is identical in size and edge quality, ensuring a high degree of product consistency.

The fully automatic CNC carpet cutting machine can greatly improve production efficiency, reduce production costs, and improve the accuracy and quality of carpet processing.

If you have specific equipment needs or questions, please continue to ask questions.