The working process of EPE foam board CNC cutting machine:

First, the operator needs to prepare a suitable EPE foam board. Make sure the EPE foam board has no obvious damage or deformation. Then check the status of the foam cutting machine. Including the sharpness of the knife, whether the electrical system is normal, etc.

Place the EPE foam board on the cutting table of the foam board cutting machine. The vacuum system firmly fixes the foam board on the cutting table. This ensures that the foam does not move during the cutting process and maintains good precision.

Turn on the CNC foam cutting machine and set up the machine. Adjust the cutting parameters, such as speed, knife depth, etc. These parameters are determined by the thickness and hardness of the EPE foam. The complexity of the cutting shape will also affect the parameters.

For thin EPE foam, you can increase the cutting speed to improve cutting efficiency. For thicker or harder EPE foam, you need to reduce the cutting speed and increase the cutting depth to ensure the cutting quality.

Before batch cutting, you can do a trial cut to observe the cutting effect. According to the trial cutting results, further adjust the cutting parameters until the best cutting effect is achieved.

After the foam CNC cutting machine is set up, it can start formal cutting. The high-speed rotating motor drives the cutting blade to vibrate at high frequency, and the foam cutting machine blade cuts through the EPE foam sheet.

Blade vibration can reduce the friction between the blade and the foam. It makes the cutting speed faster and the cutting edge smoother.

The operator needs to pay attention to the cutting situation at all times to ensure that the machine works normally. If there is a problem during the cutting process, it is necessary to stop the machine for inspection.

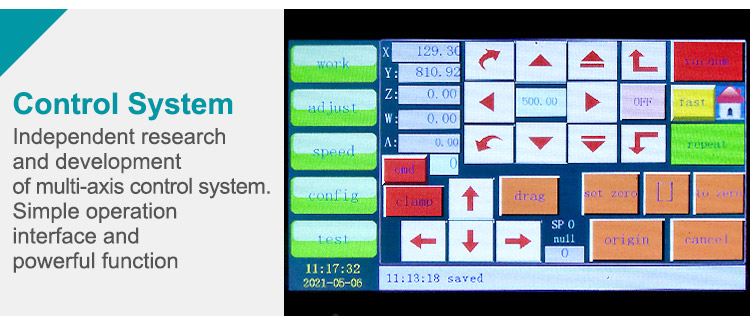

For cutting of complex shapes, you can design drawings through CAD software such as AutoCAD, and then import the drawings into the foam board cutting machine. The control system will control the blade movement according to the graphics to achieve precise cutting.

After the cutting task is completed, turn off the power of the foam cutting machine. Remove the cut EPE foam from the workbench for quality inspection.

If the cutting quality is good, the EPE foam can be processed or packaged later. If there is a quality problem, it is necessary to analyze the cause and take corresponding measures to improve the quality.

At the same time, clean and maintain the CNC foam cutting machine. Clean the EPE foam residue on the workbench, check the wear of the tool, and replace the tool in time if necessary. Lubricate and maintain each component of the equipment to extend its service life.

Features of EPE foam board CNC cutting machine:

High precision: CNC technology enables high cutting accuracy, which can reach the millimeter level, suitable for making complex shapes and sizes.

High efficiency: Automated operation reduces manual intervention, improves production efficiency, and is suitable for mass production.

Strong flexibility: The cutting program can be quickly adjusted according to different product requirements to meet diverse market needs.

Reduce waste: Precise cutting reduces material waste and improves resource utilization.

EPE foam board CNC cutting machine has become an indispensable and important equipment in modern manufacturing industry due to its high efficiency, precision and flexibility. With the continuous advancement of technology, CNC cutting machine will play an important role in a wider range of fields, improving production efficiency and product quality.

AOL intelligent blade cutting machine has high precision and high efficiency. Our professional after-sales service can provide automatic cutting solutions for various industries.

For more information, please consult:

Email: [email protected]

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://aollaser.net/