The automatic feeding recognition cutting machine is equipped with an intelligent control system, which can realize intelligent monitoring and control of the processing process. The intelligent control system can maximize production efficiency by adjusting and optimizing processing parameters in real time. For example, the system can intelligently adjust cutting speed, tool pressure and cutting path according to the material, size and shape of the workpiece to achieve the best processing effect and improve production efficiency.

The automatic feeding recognition cutting machine adopts an advanced intelligent recognition system to realize automatic recognition and positioning of workpieces. The system intelligently identifies the shape, contour and features of the workpiece to accurately determine the cutting position and path, thereby improving processing accuracy. The intelligent identification system can also monitor various parameters during the processing process in real time, detect and correct processing errors in a timely manner, and ensure the stability and consistency of processing accuracy.

The automatic feeding recognition cutting machine is equipped with an intelligent data management system, which can realize data collection, analysis and management of the production process. Through real-time monitoring and analysis of processing data, the system can promptly discover problems and bottlenecks in the production process and propose corresponding optimization plans.

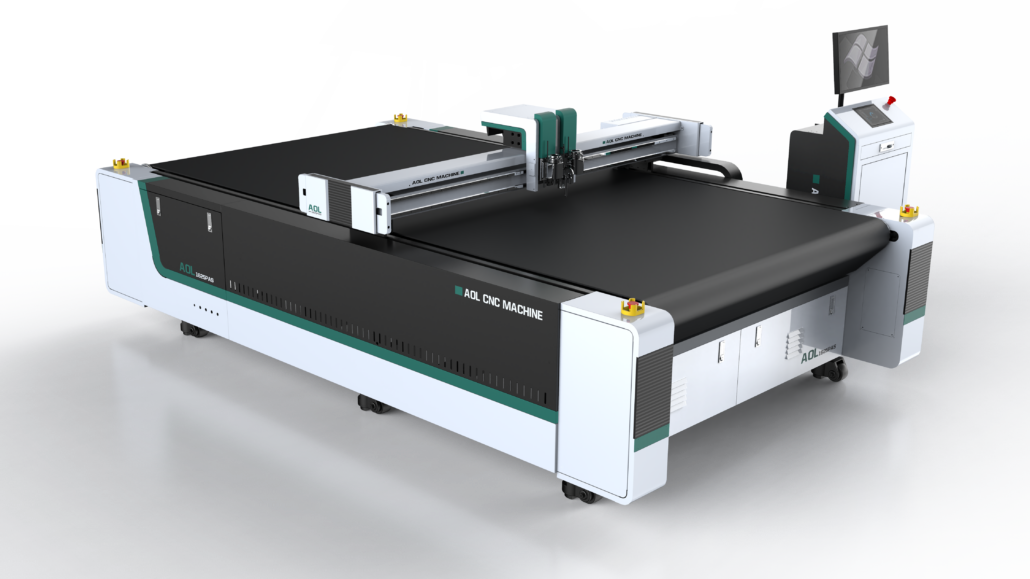

The automatic feeding recognition cutting machine is equipped with an intelligent human-computer interaction interface, which can realize intelligent interaction with the operator. Through the intuitive and friendly operation interface, operators can easily perform equipment parameter setting, process adjustment, production monitoring and other operations, thereby improving operating efficiency and work efficiency.

The degree of intelligence of the automatic feeding recognition cutting machine has an important impact on its performance. Through the continuous optimization and improvement of intelligent control systems, intelligent identification systems, intelligent data management systems and intelligent human-computer interaction interfaces, automatic feeding identification cutting machines can achieve more efficient and accurate processing results, providing benefits to the manufacturing industry.