Advanced textiles are constantly evolving to meet the changing needs of law enforcement, outdoor enthusiasts, athletes, designers and more. The large volume of advanced, technical and engineered textiles and their numerous applications means that manufacturers are looking for flexible cutting solutions.

While industrial fabrics may have been used only in high-tech applications in the past, they are now used in everything from personal entertainment devices to transportation-grade upholstery. Traditional cutting methods may not be precise enough if you are cutting textiles for outdoor furniture, fabric construction such as awnings, outdoor gear including backpacks, tents and inflatables, military and law enforcement equipment or marine and transportation grade upholstery and carpet , powerful or efficient.

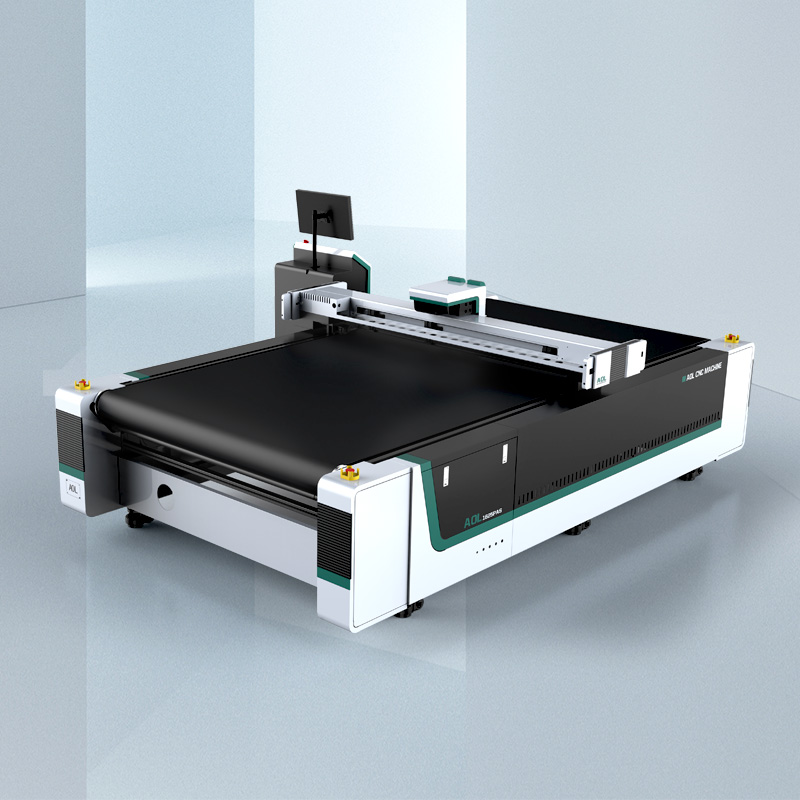

Your premium textile cutting machine should be tailored to your specifications. AOL’s cutting and processing solutions are fully customizable. Cutting tables are available in various widths and lengths. Your tool head can also be equipped according to your needs, including round knife, drag knife, punch and marking options. Our cutting surfaces are available in a variety of chip-free materials and are compatible with vacuum compaction systems to suit your specific technical textiles and cutting method.

Automatic cloth cutting machines are computer controlled to ensure accuracy and repeatability. We offer a variety of software to increase productivity and eliminate waste—both essential when dealing with expensive specialty materials. All of our software integrates seamlessly with major CAD formats. This allows design changes to be implemented on the cutting room floor almost instantly.

To save time and reduce errors, crop dailies even if they are longer than your table. Our equipment allows your conveyor belt cutting system to continuously cut fabric while it is being conveyed.

When you choose AOL for your textile cutting machine, you are choosing more than just a piece of equipment. Our machines come standard with a knowledgeable sales team and ongoing technical support. We’ll help you find the right cutting, handling and software solutions for your specific material and end use. Our hands-on process includes trial cuts using your material. We encourage you to contact us directly to discuss your unique application needs.