AOL digital cutting machine is suitable for composite materials industry. It can cut a variety of composite materials such as aramid cloth, carbon fiber, prepreg cloth, glass fiber, and ceramic fiber. Therefore, the cutting machine suitable for the composite material industry is also called the composite material cutting machine.Many customers say that I have a lot of materials, how do I choose the configuration and tools of the cutting machine?Because AOL has 10 years of experience in serving composite materials customers, here is how to choose the most suitable configuration for commonly used composite materials when buying a cutting machine.

1. First look at what cutting tools are needed for carbon fiber?

What is carbon fiber?

High-strength and high-modulus fiber with carbon content above 90%. High temperature resistance ranks first among all chemical fibers. It is made of acrylic fiber and viscose fiber as raw materials, which are oxidized and carbonized at high temperature. It is an excellent material for manufacturing high-tech equipment such as aerospace and aviation.

Two thicknesses are available: 0.111mm (200g) and 0.167mm (300g). Various widths: 100mm, 150mm, 200mm, 300mm, 500mm and other special widths required by projects.

Recommended tool selection: Driven Rotary Knife Tool

Blade selection Y025a

Because carbon cloth is the raw material of processed products, the carbon fiber compression molding process mainly includes four steps: preheating-feeding-clamping-curing-demolding. The produced carbon fiber products are polished and processed into finished products. There is a lot of allowance to be left during the blanking, so the cutting precision is not required! Customers can accept the error within 1 mm

Therefore, it is generally recommended that customers choose belt feeder.

2. What kind of tool do I need to choose for cutting the pre-feed?

What kind of allowances are there?

Prepregs are divided into unidirectional prepregs, unidirectional fabric prepregs, and fabric prepregs; according to different resin matrix, prepregs are divided into thermosetting resin prepregs and thermoplastic resin prepregs; according to different reinforcing materials, they are divided into carbon fiber (Fabric) prepreg, glass fiber (fabric) prepreg, aramid (fabric) prepreg; according to the curing temperature, it is divided into medium temperature curing (120℃) prepreg and high temperature curing (180℃) prepreg And prepregs whose curing temperature exceeds 200℃.

It is recommended to use a vibrating knife, and choose different blades according to different material thicknesses

Processing technology and precision requirements of prepreg:

Carbon fiber prepreg is made by combining epoxy resin with carbon fiber through high pressure and high temperature technology. The composite material made of carbon fiber yarn, epoxy resin, release paper and other materials through coating, hot pressing, cooling, laminating, coiling and other processes is called carbon fiber prepreg, also known as carbon fiber prepreg. Pre-impregnated cloth can be directly processed into products through the mold, and the accuracy requirements are relatively high. Some customers require the cutting accuracy to be less than 5 wires, and it is best to choose a rack machine!

3. What kind of tool do I need to choose for cutting glass fiber?

Fiberglass checkered cloth is a non-twisted roving plain weave fabric, which is an important substrate for hand-laid fiberglass. The strength of gingham cloth is mainly in the warp and weft direction of the fabric. For occasions that require high warp or weft strength, it can also be woven into unidirectional cloth. It can arrange more untwisted rovings in the warp or weft direction. Warp cloth, single weft cloth.

It is recommended to choose a round knife

Fiberglass cloth is usually used as a reinforcing material in composite materials, electrical insulation materials and thermal insulation materials, circuit boards and other fields of the national economy. 2. Glass fiber cloth is mostly used in hand lay-up process. Glass fiber cloth is mainly used in hulls, storage tanks, cooling towers, ships, vehicles, tanks, etc. 3. Glass fiber cloth is widely used in wall reinforcement, exterior wall insulation, roof waterproofing, etc. Due to the characteristics and uses of the material, the cutting accuracy is not required! The customer accepts the error is about 1 mm

Generally, a belt feeder is recommended, and a rack machine is recommended if the cutting requirements are strict.

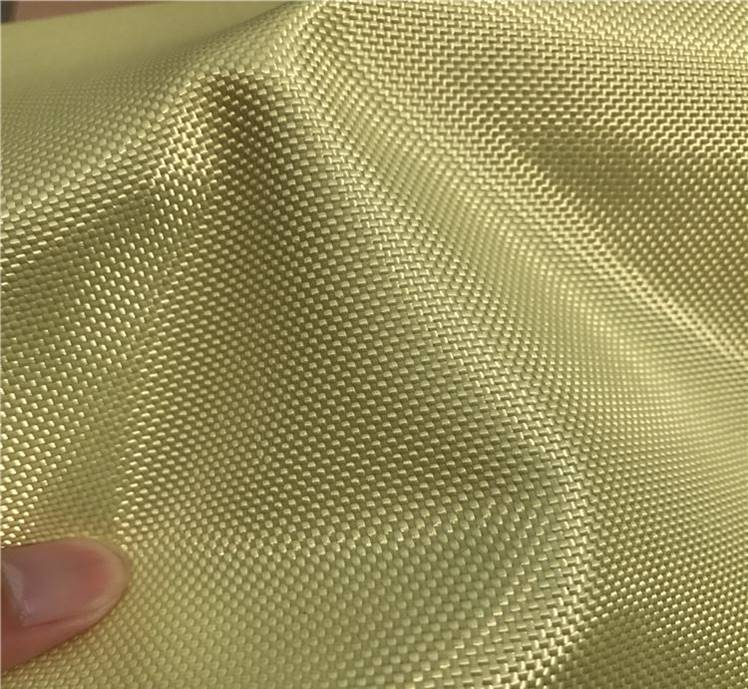

4. What kind of tool should I choose for cutting aramid cloth?

What is the material of the aramid cloth? Aramid cloth is a new type of functional fabric. It is a chemical fiber fabric, also known as Kevlar. The textile fiber is aramid fiber, which is also a chemical fiber fiber like polyester nylon. ! What is the use of aramid cloth?

1. Low-gram weight aramid fabric is a good bulletproof fabric, which can be used to process high-performance bulletproof vests!

2 Unidirectional aramid fabric, due to its high tensile strength in one direction, can be used in the construction industry, such as earthquake relief, bridge reinforcement, etc.!

3. Aramid non-woven fabric is a very good insulation material!

4. Aramid twisted webbing is a plain weave, and its main function is electrical equipment parts and automotive hoses! 5. Aramid fabric three-dimensional structure fabric is mostly used in the aviation field!

Recommend to choose vibrating knife

5. Prepreg: Regardless of carbon fiber, glass fiber or aramid fiber material

the prepreg is an air impermeable material, so the cutters are all vibrating knives! The width of the material is 1 meter wide, and it is basically a roll of 100 meters long. material. Recommend 1625 automatic feeding machine! (Note: some customer products have a longer single piece length, and the machine can be lengthened according to customer requirements

Other: Carbon cloth recommends vibrating knife

Regardless of carbon cloth, glass fiber cloth, or aramid cloth, they are all woven cloths. The materials are all breathable. They are usually cut and cut with a round knife. Carbon cloth is usually not more than one meter wide. Follow-up customers need to have individual manufacturers who can do the widest. 2.5 meters wide. Glass fiber cloth is usually one meter to two meters wide, and aramid cloth can usually be within 2.5 meters in width. Therefore, the machine model can be recommended to customers according to customer materials and width requirements!