Problems currently faced by gasket manufacturing:

The headache of custom cutting, slow delivery, sky-high tooling costs, a huge quest for skilled workers, and mountains of production costs.

Carefully crafted molds, only to let your customers change the design or dimensions at will?

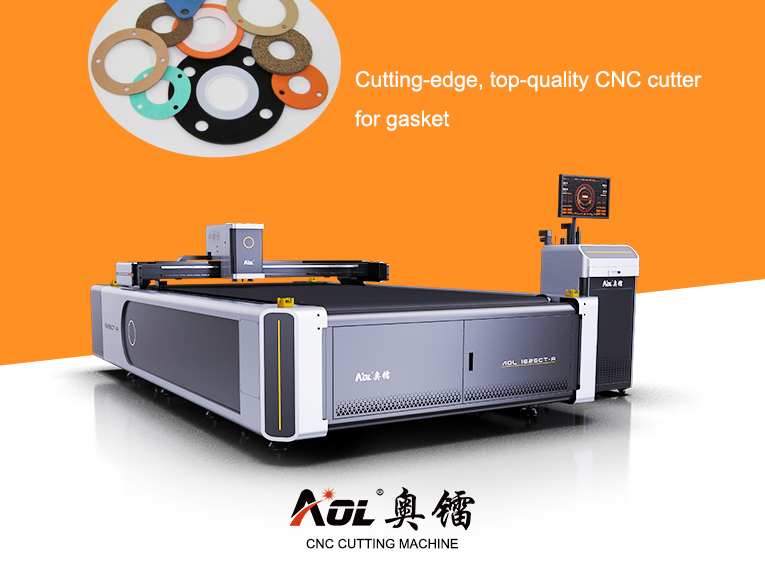

That’s why more and more gasket manufacturers are looking for a cutting solution that’s flexible, smart, and won’t break the bank. CNC vibrating knife cutting machines have become the first choice for many people.

If you’re keen to learn how to choose a high-quality CNC gasket cutting machine, read on for insightful guidance.

Need a CNC gasket cutting machine but not sure how to choose? Don’t worry. Tell AOL CNC whether you want to cut asbestos-free board, rubber, graphite board, or epoxy board, and we will recommend the most appropriate tool configuration based on your needs!

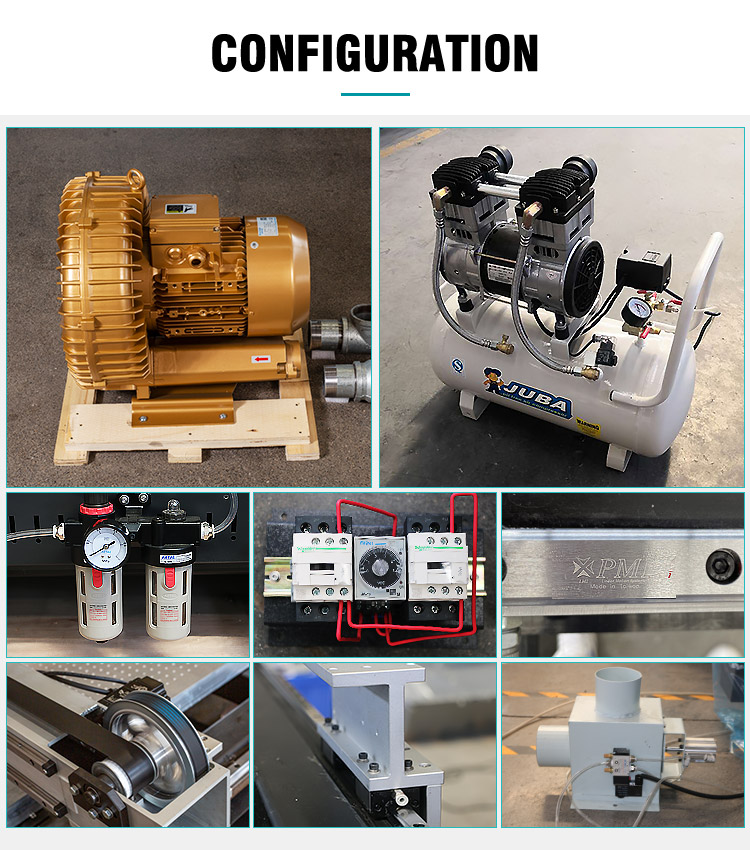

Once the configuration is determined, the stability and efficiency of the machine largely depend on the quality of its components. Then you need to pay attention to the following points:

1. Servo motor: We exclusively use Japanese Panasonic servo motor, which is famous for its stable performance and excellent servo rigidity.

2. Low-voltage equipment: Use low-voltage components such as relays, AC contactors and circuit breakers from French Schneider Electric. This ensures smooth and uninterrupted operation of our machines’ electrical systems.

In addition, our machines use high-grade components from all over the world, including Italian belts, Taiwan guide rails, German cable drag chains, etc.

If you want to cut to perfect size every time, you not only need high-quality equipment, but also a scientific production process:

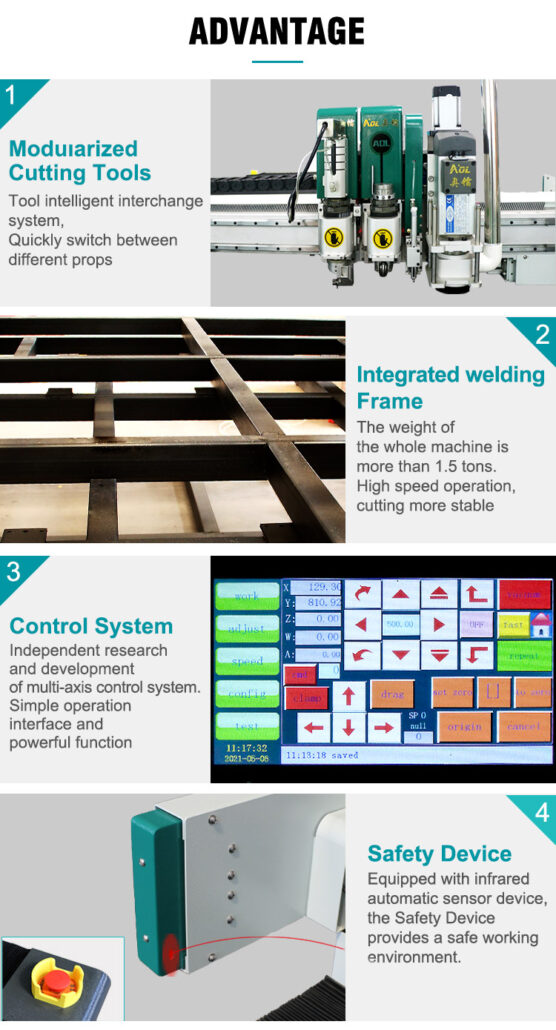

1. High-quality bed: The bed of a machine is very important, just like laying a good foundation when building a house. However, many customers will ignore this, leading some vibrating knife cutting machine manufacturers to reduce costs on the bed.

The bed of the CNC cutting machine is welded from 6mm thick square tubes to form a solid base. After a high-temperature heat treatment of about 800 degrees, the internal stress of the steel is released (to ensure that the accuracy of the equipment remains unchanged for a long time). After natural cooling, the milling machine is fine-machined to ensure that the bed accuracy error is within ±0.05mm.

This design minimizes vibration during high-speed machining and prevents the bed from warping, providing a stable foundation for precision cutting.

2. Motor + gear drive: Many customers will ask why they choose this method? The reason is that the belt easily expands due to heat and mechanical stretching during continuous cutting, thereby reducing accuracy. So use the motor + gear method.

3. Rack and pinion meshing: The rack and pinion are tightly fixed together to prevent gaps from forming due to long-term operation of the machine. This gap is the direct cause of inconsistent cutting sizes or incomplete circles.

4. High-strength knife holder system: The vibrating knife cutting machine cuts materials by rapidly vibrating the knife up and down. Continuous vibration poses challenges to tool holder systems, especially when using high-power vibrating tools to cut hard materials, such as non-asbestos or PTFE gasket materials, where vibration forces increase significantly. This requires the tool holder system to have excellent anti-vibration design.

Perfect after-sales team:

Choosing AOL CNC means more than just getting a high-quality CNC gasket cutting machine; it means getting a reliable partner. After purchasing our machine, a service team will be formed for you, including AOL sales staff, AOL engineers, AOL sales managers, AOL sales directors and you (or your employees). If you have any questions, we will reply within 1 minute.

The relevant introduction to cutting equipment comes to an end here. If you want to continue to learn more, you can learn more and contact us through the following methods, and we will give you detailed answers as soon as possible!

Email: [email protected]

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://aollaser.net/