Cutting video

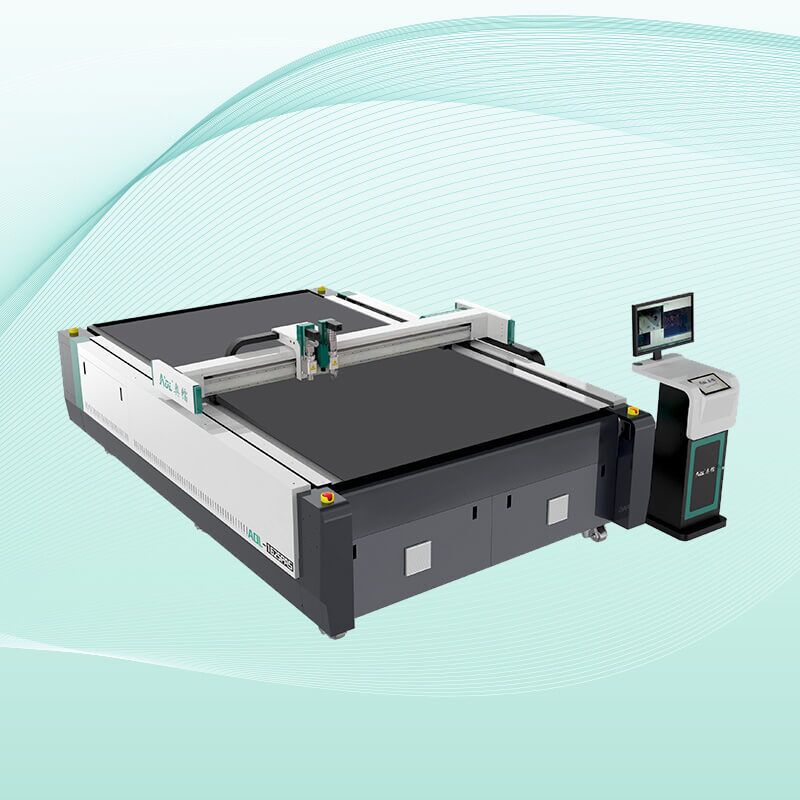

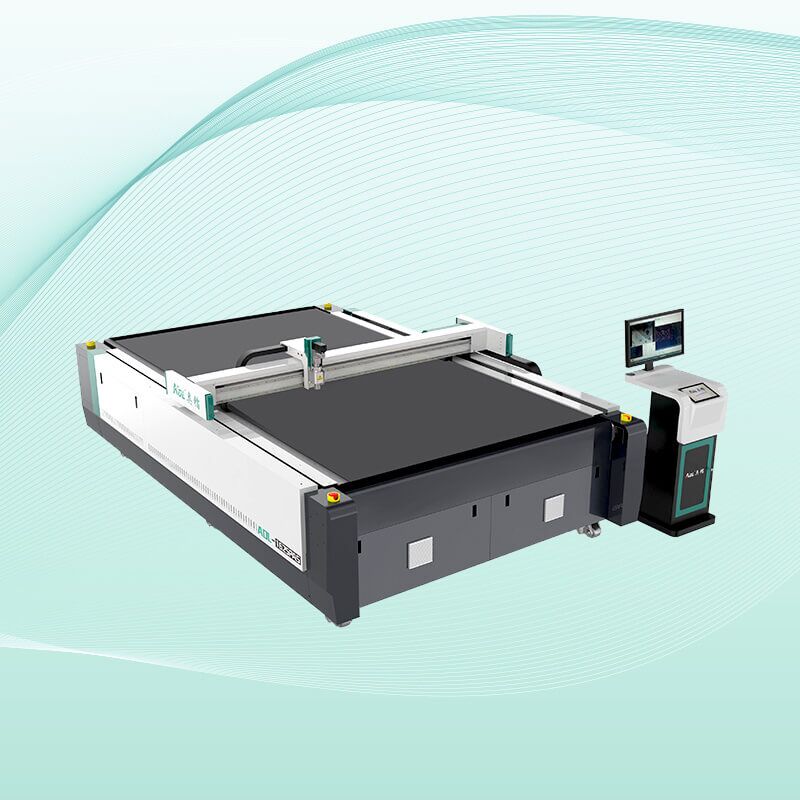

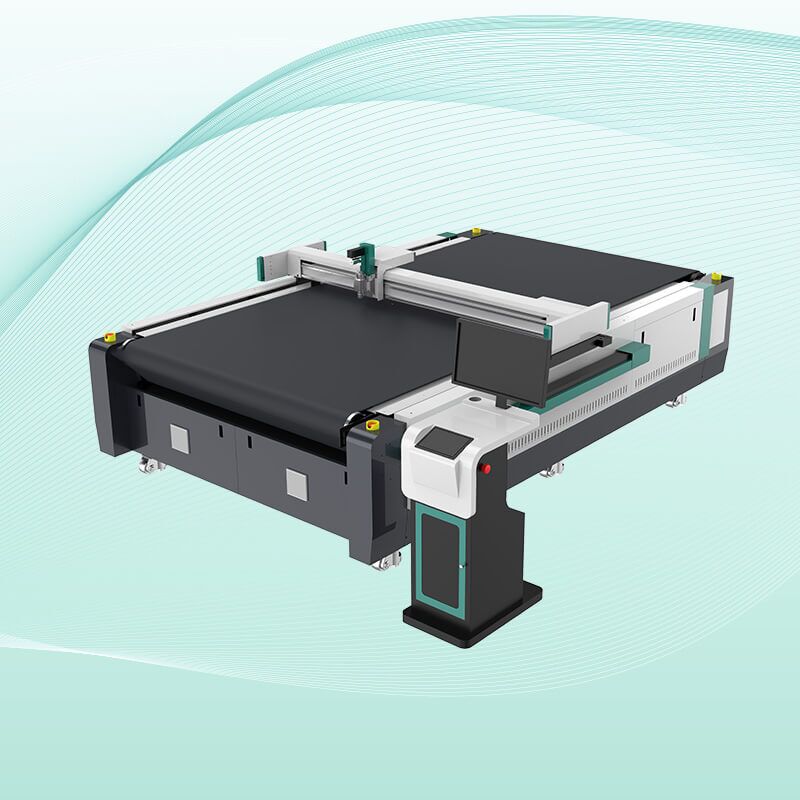

Advantage of Garment Pattern Cutting Machine for Fabric

1. Saving labor and material cost

2. Saving time

3. Everyone can operate and cut without lots of skills

4. Boost production capacity

5. Consistent accuracy even with complicated patterns

6. Reduces your lead times of pattern cutting from your clients

7. Wide range of clothes/garment/apparel material application

8. Running in a high automaton

9. Special design: less moving structure guarantee low down time and easy in installation and maintain

10. Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

11.Good experienced engineers

12. CNC control 13. Knife cutting method: oscillating Blade with multifunctional tool heads 14. Easy conversion

Application of Garment Pattern Fabric Cutting Machine

Automatic Garment Pattern Cutting Machine is not only applicable to the textile industry, but also applicable to gasket, leather, cardboard, plastic, paper, rubber, EVA foam, and it can cut many types of foam, such as closed cell foam, rubber foam, foamex, foam core, KT board, EPE foam, polyethylene foam, PE foam, PVC foam, etc. It’s widely used for packaging protection, advertising display, termal insulation, model & mock up making, puzzle and pattern cutting, etc.

Specifications of Garment Pattern Fabric Cutting Machine:

| Technical parameters / model | AOL-1625-ZS6 | AOL-1825-ZS8 | AOL-2125-ZS10 | Accept special model customization | ||

|---|---|---|---|---|---|---|

| Effective working area | 1600x2500mm | 1800x2500mm | 2100X2500 | |||

| Multi-head optional | Double head optional efficiency doubled, double gantry optional, double head mutual shift optional, length can be customized | |||||

| Multi-function tool | Vibrating knife full cutting, high power active round knife, punching tool, pneumatic knife, multi-layer knife | |||||

| safety devices | Safety devices use infrared sensing, safe and reliable | |||||

| Cutting speed | 200-2000mm/s | |||||

| Cutting thickness | ≤50mm Other thicknesses can be customized according to the material | |||||

| Applicable materials | cotton, linen, silk, blends, fibers, leather, wool, modal | |||||

| Material fixing method | Vacuum partition adsorption | |||||

| Transmission port | Network port | |||||

| Transmission system | Yaskawa servo motor, linear linear guide, timing belt, lead screw | |||||

| rated power | 11kw | |||||

| Rated voltage | 380V±10%/220V±10% Optional | |||||

| Control System | Chinese and English LCD touch screen | |||||

| Operating environment | Operating environment Temperature 0-40°C Humidity 20%-80%RH | |||||

| Software | Automatic nesting software, template entry software(Optional) | |||||

| Support file format | AI、PLT、DXF、CDRetc | |||||

| Overall size | 3570x2290x1165mm | 3570x2500x1165mm | 3570x25800x1165mm | |||

Why Choose Automatic Garment Pattern Cutting Machine

AOL CNC

Performance of Garment Pattern Cutting Machine for Fabric

1、Welded structure by thick steel tube welding under high temperature, ensures minimum distortion, excellent rigidity and powerful strength.High accuracy, long service time, steady movement.

2、Adopt linear guide rail, make sure the machine square the accuracy and can withstand large load.

3、Mechanical and electrical design, selection of straight excellent brand electrical accessories.

4、9KW HSD ATC spindle power changeknife spindle to ensure the machine can be vigorous cutting.

5、Breakpoint power function for carving.

6、Auto lubricating system, one touch can finish periodic maintenance easily.

7、Intelligent protection work to prevent incorrect operation etc mesa, may cause the damage of mesa.

8、New function add oscillating knife for cutting soft materials such as gasket, rubber, PVC,carton, PU.

Reasons for choosing AOL CNC equipment

1.High technology enterprise in China AAA Credit Enterprise, AAA heavy contract

2. Has 58 national R&D patents

3. The whole series of products have passed the national quality system certification

4. All series of electrical products are selected from leading brands in the industry

5. More than 25000+ customers worldwide

6. AOL promises to enjoy a three-year warranty service for all products

7. AO promises lifetime free technology upgrades and free software upgrades.

Service OF AOL

1.Three years warranty, main parts are free of charge when problems happened during the guarantee period.

2.We provide the consumable parts at the agent price when you need replacement.

3.24 hours online service each day, free technical support with different languages.

4.We provide door-to-door technical support, if necessary.

Media of AOL

The price of CNC knife cutting machine, Please inquire and tell us your cutting material and size.

If you want to know the price of the digital gasket cutting machine, please send us the name, size and thickness of the material to be cut, so as to give you the most detailed quotation.

More autimatic gasket cutting machine for sale, welcome to visit https://www.aollaser.net/

Reviews

There are no reviews yet.